The story of aerosols started in 1927. Erik Rotheim made the first aerosol spray can and got a patent. This new idea used a pressurized system with a valve. It changed how people use and spray products. Over many years, aerosol cans became part of daily life. People use them for cleaning and personal care. Aerosol cans were also important in industry and war. Today, new ideas focus on helping the environment. For example, GDB International recycles millions of aerosol cans every year. They save metal, paint, and gases from these cans. The history of aerosol technology shows how it brings both ease and care for the planet.

Key Takeaways

Erik Rotheim made the first aerosol spray can in 1927. This invention gave people a safe and simple way to spray liquids. During World War II, aerosol cans helped soldiers by spraying insecticides. Later, people started using them at home too. New valves and safer gases made aerosol cans work better. They also became more reliable and safer for the environment. Scientists found that CFC gases hurt the ozone layer. This caused bans and new rules. Companies then looked for safer propellants. Today, aerosol cans use materials that are better for the earth. They are used for medicine, cleaning, and food. People now focus on recycling and safety.

Early Aerosol Concepts

Carbonated Beverages

The path to modern aerosol cans started long ago. People had ideas about pressurized containers in the late 1700s. They wanted to spray or pour liquids more easily. Carbonated beverages were very important in this process. Factories needed to keep drinks bubbly and safe in bottles. Machines controlled pressure so carbon dioxide would not escape.

Carbonation needed strong pressure to mix gas with the drink.

Special filling heads stopped drinks from foaming up.

Sealing stations made sure bottles did not leak.

Safety valves and leak detectors kept workers and products safe.

These systems showed why pressure control mattered for containers. Stainless steel pipes and temperature controls kept drinks fresh and safe. These changes in carbonated drink technology taught engineers about pressure. This helped lead to the first aerosol cans.

Regency Portable Fountain

In the early 1800s, inventors made things like the Regency Portable Fountain. This device let people spray liquids by using pressure. It worked by pumping air into a container. The air pushed the liquid out when released. The Regency Portable Fountain was popular at parties for serving drinks. It also gave people new ideas for spraying other things.

By the 1920s, inventors mixed these ideas with new materials and propellants. In 1927, a Norwegian engineer got a patent for a can and valve system. This system used pressure to spray liquids. It became the main design for modern aerosol cans. During World War II, engineers made spray cans for insect repellents. Soldiers used millions of these cans. By the late 1940s, aerosol products were in stores and homes across the United States.

Early ideas like carbonated beverage machines and the Regency Portable Fountain helped inventors solve problems with pressure, safety, and control. These ideas led to the first useful aerosol cans.

Invention of Aerosol Spray Can

Erik Rotheim's Patent

Erik Rotheim was a chemistry student. He wanted to fix real-life problems. He studied at Karlsruhe and liked making new things. In 1927, he got a patent for the first aerosol spray can. His invention used a metal can, a valve, and a special gas. This let people spray liquids safely and evenly. Rotheim's design was the first real aerosol can. It became the model for today's cans.

Rotheim's invention had some problems at first. The first cans could catch fire and cost a lot to make. Still, his idea had important features that changed everything:

Pressurized container kept things safe

Valve system let people spray with control

Gas propellant spread the liquid evenly

These features helped people use the right amount, waste less, and carry cans easily. Other inventors later made the technology better. Rotheim's patent started the worldwide aerosol industry.

Rotheim's work proved one invention can change many things. It helped people find new ways to use and keep liquids.

WWII and Bug Bomb

During World War II, soldiers needed better ways to fight bugs. Mosquitoes spread diseases in hot places. Lyle Goodhue and William Sullivan worked at the USDA. They wanted to help soldiers stay healthy. In 1941, they made the first spray pesticide. Their device was called the "bug bomb." It used aerosol technology to spray bug killer as a mist. This invention kept soldiers safe from malaria and other sicknesses.

Goodhue and Sullivan's bug bomb used a pressurized can with insecticide and Freon 12. They tested it under pressure and showed it worked. The USDA said their design was good. Westinghouse Electric helped make the first cans. The military made over 40 million bug bombs during the war. These cans became very important for the U.S. Army.

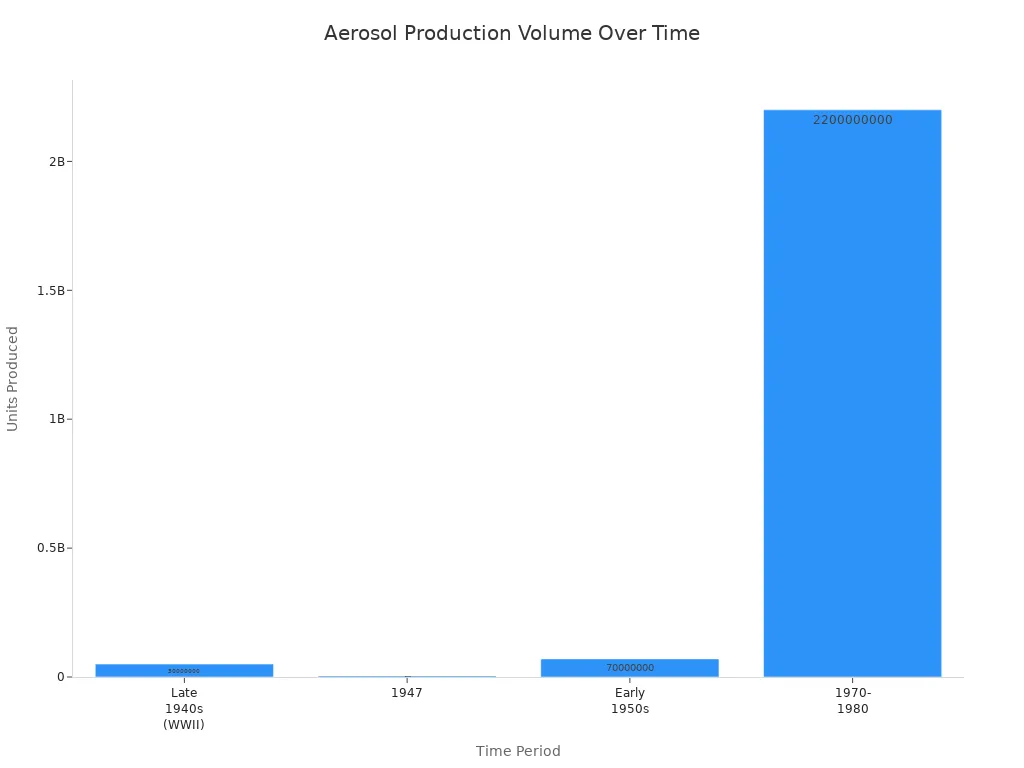

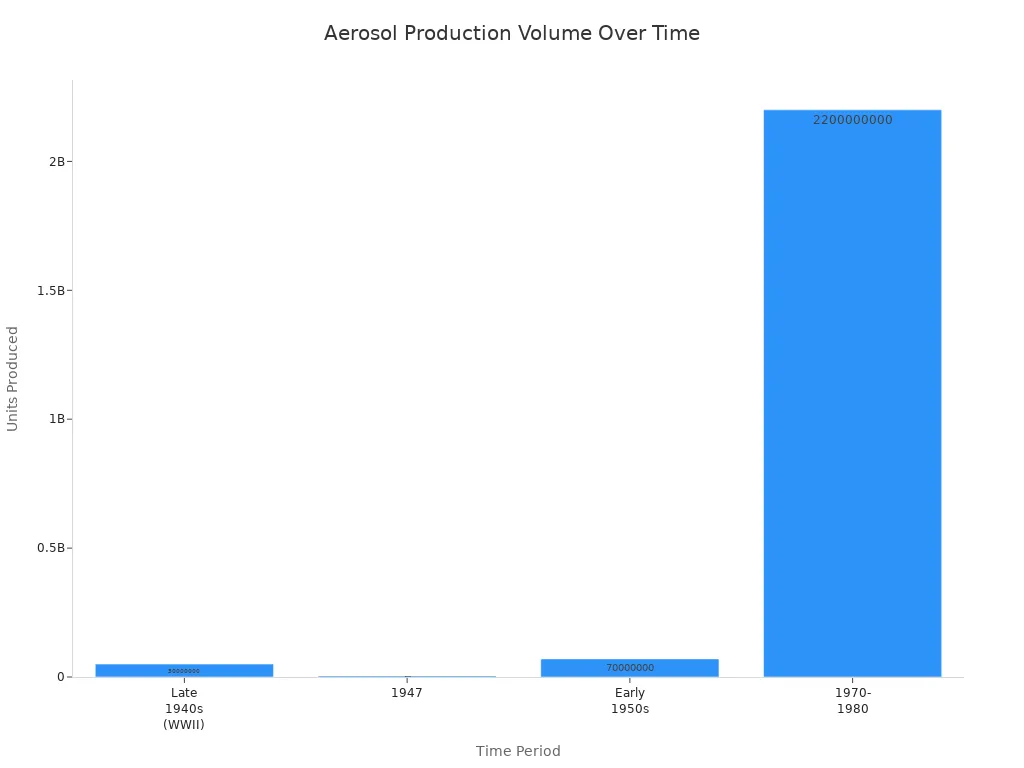

Time Period | Military Use | Civilian Use and Impact | Production Volume |

Late 1940s (WWII) | Aerosol insecticides ("bug bombs") used by U.S. military to protect soldiers from insect-borne diseases | N/A | 50 million units produced during WWII |

1947 | N/A | Civilian markets began using aerosol products like insecticides | 4.3 million units for civilian use |

Early 1950s | N/A | Insecticides and hairsprays introduced in Europe | 70 million units in Europe (1950-1960) |

1960-1970 | N/A | More aerosol products, new can materials | Production increased (exact numbers not specified) |

1970-1980 | N/A | Continued growth, environmental concerns | 2.2 billion units, 80% increase in 10 years |

The bug bomb changed life for soldiers and regular people. After the war, companies used aerosol cans for many things. People bought insecticides, hairsprays, and cleaners for their homes. The technology that started for soldiers soon helped everyone.

The bug bomb showed how one invention could save lives and create new products for all.

Advancements in Aerosol Cans

Valve and Propellant

After the first aerosol package, inventors wanted to make it better. In 1949, Robert H. Abplanalp made a new valve. This valve was cheaper and easier to make. Companies could now make millions of cans for many things.

Modern valves do more than just open and close. They control how much comes out and the spray shape. Some valves make a soft mist for perfumes. Others make a strong spray for cleaners. Factories use lasers and robots to build these valves. This helps make each can safe and dependable.

Many valves now use tough plastics. These plastics last longer and do not rust. Some valves can change the spray or flow. This helps people use just what they need.

New propellants also changed the industry. Early cans used gases that could catch fire. Today, many cans use air or nitrogen. These gases are safer and do not burn. Some cans have a bag-in-can system. The product is inside a bag, and gas is outside. This keeps the product clean and lets people use almost all of it.

Here is a table that shows how new valves and propellants made cans safer and better:

Improvement Aspect | Description and Impact on Safety and Efficiency |

Product Purity | Bag-on-valve (BOV) keeps product and gas apart, so the product stays clean and works well. |

Spray Efficiency | BOV gives a fine mist and even spray, making the product work better. |

Product Utilization | BOV lets people use almost all the product, so less is wasted. |

Propellant Safety | Air and nitrogen do not burn, so they lower fire risk and pollution. |

Environmental Impact | Inert gases help cut greenhouse gases and follow new rules. |

Cost and Quality | BOV costs more at first, but it gives better quality and happier customers. |

Today, companies use many kinds of valves and propellants. Some valves give a steady spray. Others give a set amount, which is good for medicine. New propellants like hydrofluoroolefins (HFOs) help the environment. Factories use recyclable materials for cans and valves. Some smart valves even use sensors to control the spray.

Strong plastics make valves last longer.

Multi-use valves let people pick the spray they want.

Recyclable aluminum and plastics help the earth.

Bag-in-can systems help cut waste.

Smart valves use electronics for better control.

These changes make aerosol cans safer, cleaner, and better for the planet.

Mass Production

Abplanalp's new valve changed how companies made aerosol cans. Factories could now make millions of cans every year. In the 1950s, one U.S. company made over one billion cans. Other countries made half a billion more. Company sales went over $100 million at this time.

Here is a table that shows how aerosol can production grew:

Time Period | Key Data Point / Milestone |

1927 | First patent for the aerosol spray can |

1930s | Propellants were developed |

World War II | Over 30 million aerosol cans sent to U.S. Army and Air Force |

1950s | Abplanalp's company made 1 billion cans in the USA |

1950s | Half a billion cans made in other countries |

1950s | Company sales went over $100 million |

1970s | Aerosol can production grew by over 80% |

Factories used new machines to make cans faster and cheaper. Robots and computers checked for leaks and safety. Companies used more recyclable metals and plastics. Energy-saving machines helped the environment.

Factories made more cans every year.

Machines checked cans for leaks and safety.

Recyclable materials became more common.

Energy-saving steps cut power use and pollution.

Mass production made aerosol cans part of daily life. People used them for cleaning, beauty, medicine, and food. The industry kept growing as people found new uses.

Today, the aerosol can industry keeps changing. Companies focus on safety, quality, and the environment. They use smart machines and better materials. These steps help people and protect the planet.

Regulation and Environment

CFCs and Ozone

A long time ago, many aerosol cans used CFCs as propellants. In the 1970s, two scientists found out something important. They learned that CFCs float up into the stratosphere. There, sunlight breaks them apart. This lets chlorine atoms escape. The chlorine destroys ozone molecules. The ozone layer keeps Earth safe from UV-B rays. If the ozone gets thin, more UV rays reach us. This can cause skin cancer and other health problems. In 1985, scientists found a big ozone hole over Antarctica. This showed the problem was very serious. CFCs can stay in the air for up to 140 years. So, their effects last a long time.

When people learned CFCs hurt the ozone, things changed fast. Companies like SC Johnson stopped using CFCs in 1975. Soon, governments made new rules to help.

Aerosol cans also let out VOCs. These chemicals help make smog. Smog is bad for lungs and makes it hard to breathe.

Industry Response

Governments wanted to protect the ozone layer. In the U.S., most CFCs in aerosol cans were banned by 1978. The EPA, FDA, and CPSC worked together on new rules and labels. In 1987, many countries signed the Montreal Protocol. This treaty said CFCs had to be phased out. It became a very successful plan for the environment.

The aerosol industry changed quickly. Companies spent money to find safer propellants. They used HFCs, air, nitrogen, and carbon dioxide. Many switched to bag-on-valve systems. These keep the product and propellant apart. Big brands like Procter & Gamble and Unilever led the way. They used propellants that do not harm the ozone. Today, natural propellants are common. But companies still look for even safer choices.

Year | Major Action | Impact |

1975 | SC Johnson removes CFCs | Industry sets example |

1978 | U.S. bans CFCs in aerosols | CFC emissions drop |

1987 | Montreal Protocol signed | Global phaseout begins |

Now, international rules and certifications help keep aerosol cans safe. These rules protect people and the planet and build trust.

Modern Aerosol Innovations

Eco-Friendly Solutions

Today, aerosol companies work hard to help the environment. They use formulas with little or no VOCs. This means less bad gas goes into the air. Water-based spray paints are now common. These paints do not have as many harmful chemicals. Many brands pick safer propellants like carbon dioxide or nitrogen. These choices help stop fires and keep people safe.

Manufacturers add things that break down naturally to paints. They use safe colors and plant-based liquids. These steps lower chemical pollution. Packaging is changing too. Companies use cans made from aluminum and tin that can be recycled. Some cans are made from recycled metal. Recycling programs ask people to return used cans.

Many brands follow strict rules from groups like the EPA, EU REACH, and LEED. They also try new propellants that break down and ways to save energy.

Here is a table that shows some eco-friendly features in today's aerosol cans:

Feature | Benefit |

Low/Zero VOC Formulas | Less air pollution |

Water-Based Paints | Fewer toxic chemicals |

Non-Flammable Propellants | Safer for users |

Recyclable Packaging | Reduces landfill waste |

Biodegradable Additives | Better for the environment |

New Applications

Aerosol technology now has many new uses. The healthcare industry uses aerosol cans for inhalers and medicine. During COVID-19, scientists made inhaled vaccines and other treatments. These help people with asthma, COPD, and lung problems. New devices give dry powder vaccines. This helps people get shots in places without fridges.

People use aerosols for hair, cleaning, and even food. The market for aerosol cans grows every year. Companies make new products because people want easy and green choices.

Aerosol technology now helps with gene therapy, drug delivery, and special treatments. These new ideas show how innovation changes aerosol products.

The story of aerosol cans has many big changes.

Erik Rotheim's patent in 1929 was the first step.

Bug bombs in war helped save many people.

In the 1950s, sprays became popular for everyone.

The 1960s brought cans made in one piece and better valves.

In the 1970s, new rules made cans safer for the environment.

Impact Area | Highlights |

Society | Easy-to-use sprays changed how people do things. |

Environment | Recycling and green valves are important now. |

Today, companies work to make cans safer and better for the planet.

FAQ

What is an aerosol can?

An aerosol can is made of metal. It holds both a product and a gas. The gas is under pressure inside the can. When you press the valve, the product sprays out. It comes out as a mist or foam. People use aerosol cans for paint and deodorant. They also use them for cleaners and other things.

Who invented the first aerosol spray can?

Erik Rotheim was an engineer from Norway. He invented the first aerosol spray can in 1927. He made a system with a valve and pressurized gas. His idea became the main design for today's aerosol cans.

Why did people stop using CFCs in aerosol cans?

Scientists learned that CFCs hurt the ozone layer. The ozone layer protects us from harmful UV rays. After this, governments banned CFCs in aerosol cans. Companies started using safer gases instead.

How do companies recycle aerosol cans?

Companies collect used aerosol cans from people. They sort the cans and clean them. Next, machines crush the cans flat. Factories melt the metal to make new things. Recycling saves resources and cuts down on waste.

Step | What Happens |

Collection | Workers pick up cans |

Sorting | Machines separate cans |

Cleaning | Workers clean out cans |

Crushing | Machines flatten cans |

Melting | Factories melt metal |

What are some new uses for aerosol technology?

Aerosol technology is now used in many ways. Inhalers help people with asthma breathe better. Spray cheese and whipped cream come in aerosol cans. Cleaners and disinfectants also use this technology.