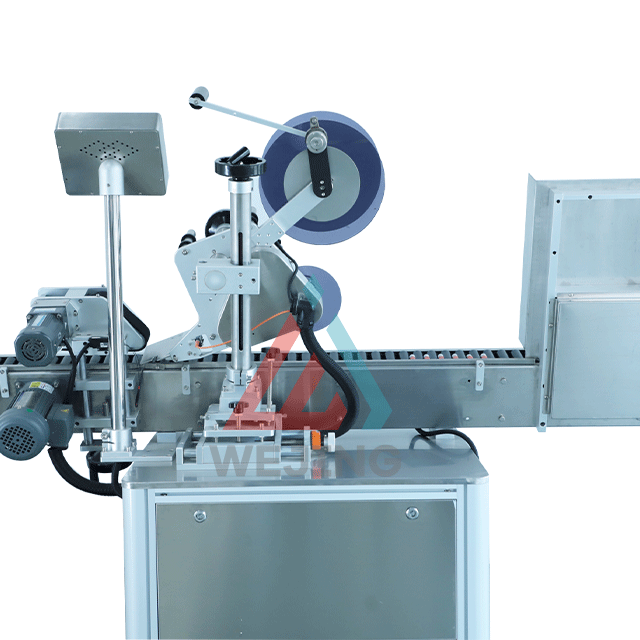

Equipment characteristics:

1. High precision: It can accurately label ampoules to ensure consistent labeling quality.

2. High efficiency: It can label multiple ampoules at the same time, improving labeling efficiency.

3. Easy to operate: It adopts a human-machine interface, which is easy to operate and can be controlled by one person.

4. Stable performance: It adopts high-quality components to ensure the stability and reliability of the equipment.

5. Flexible customization: It can be customized according to customer needs to meet different labeling requirements.

Technical Parameters:

Labeling speed | 0-100P/min (depending on product and label size) |

Labeling accuracy | ± 1mm (excluding errors such as product labels) |

Applicable product size | Diameter 15-35mm; Height 30-100mm; |

Applicable label range | Length 10-100mm, base paper width 10-100mm |

Maximum label supply | Within an outer diameter of 300 and an inner diameter of 76mm |

Environmental temperature/humidity | 0-50℃/15-85% |

Voltage | AC220V/50HZ |

Dimension | 2200*1000*1700mm(L*W*H) |

Weight | 190kg |

Product application:

1. Pharmaceutical industry: It is used for labeling small glass containers such as ampoules and vials in the pharmaceutical industry.

2. Cosmetics industry: It is used for labeling cosmetics, such as essences, serums, and lotions.

3. Food and beverage industry: It is used for labeling food and beverage packaging, such as bottles and cans.

4. Chemical industry: It is used for labeling chemical products, such as reagents and adhesives.

5. Laboratory: It is used for labeling laboratory samples and reagents to ensure accurate identification and tracking.

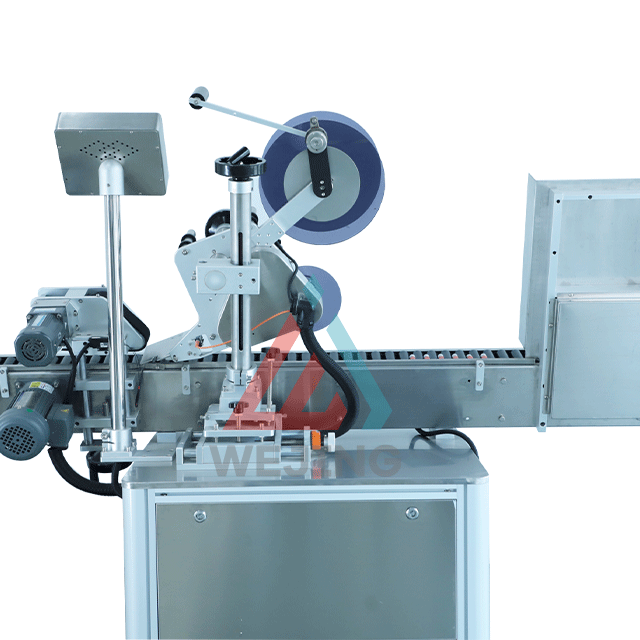

Product operation:

1. Prepare the ampoules: Ensure that the ampoules to be labeled are clean and dry.

2. Install the labels: Install the labels on the labeling machine and adjust the position and tension of the labels.

3. Adjust the speed: Adjust the labeling speed according to the production requirements.

4. Start the labeling machine: Press the start button of the labeling machine, and the machine will automatically label the ampoules.

5. Check the labeling quality: Check the labeling quality of the labeled ampoules and adjust the machine if necessary.

Common Faults and Solutions:

1. Labeling is not accurate: Check whether the label position is correct and adjust it; check whether the labeling head is clean and replace it if necessary.

2. Labeling is skewed: Check whether the label is installed correctly and adjust it; check whether the conveyor belt is smooth and replace it if necessary.

3. Labeling speed is too slow: Check whether the speed of the conveyor belt is adjusted correctly and adjust it; check whether the labeling head is working properly and replace it if necessary.

4. Labeling machine fails to start: Check whether the power supply is normal and whether the fuse is blown; check whether the switch and wiring are normal.

5. Label jams: Check whether the label is properly installed and adjusted; check whether the conveyor belt is smooth and replace it if necessary.