Product characteristics:

It is suitable for pump heads, duckbill heads, round caps and other product lock covers.

The overall design is reasonable, practical and sturdy, simple to operate, and no tools are required to adjust the height of the bottle.

Synchronize the bottle clamp cap to prevent bottle overflow.

The torque setting of the lock cover is easy and reliable.

Suitable for a wide range of product closures.

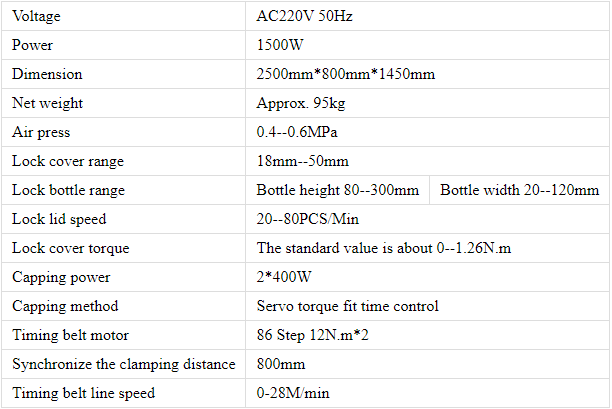

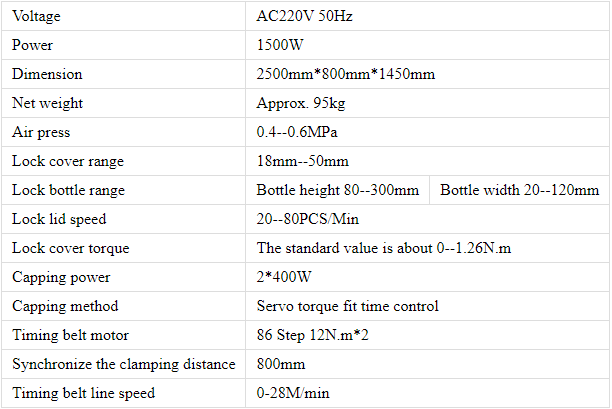

Technical Parameters:

Product Uses:

It is suitable for pump heads, duckbill heads, round caps and other product lock covers.

Product Operate Guide:

First, make sure the power to the device is connected and all the components are installed.

Then, according to the product you want to fill, adjust the filling amount and filling speed.

Next, put the product into the filling tank, press the start button, and the equipment will automatically complete the filling and sealing work.

During the filling process, you can monitor the filling of the product at any time through the observation window.

After filling, turn off the power of the equipment, clean the filling tank and seal the tail, and prepare for the next use

FAQ:

Q1: Can it handle different cap sizes?

A1: Yes, it can accommodate various cap sizes

Q2: Can I adjust the cap tightening torque?

A2:Yes, the torque settings are adjustable to customize cap tightness.

Q3:Can the machine be integrated into existing production lines?

A3:Yes, these machines can be seamlessly integrated into existing production lines, allowing for efficient workflow and synchronization with other packaging equipment.

Q4: Which industries commonly use these machines?

A4 Industries such as food and beverage, pharmaceuticals, and cosmetics commonly use them for secure and consistent capping.

Q5: Is it easy to clean and maintain?

A5: Yes, it is designed for easy cleaning and requires minimal maintenance.