Introduction

Tube sealing plays a vital role in packaging, ensuring product protection and freshness. Without a proper seal, products can become contaminated or leak, affecting quality and safety.

In this article, we’ll explore various tube sealing techniques, their benefits, and the best use cases for each. You’ll learn how different methods work and which one is best suited for your business needs.

| Sealing Method | Advantages | Disadvantages |

| Hot Air Sealing | Fast, versatil

e, works with different materials, strong seal | Needs equipment for various tube sizes, costly maintenance |

| High-Frequency Sealing | Strong, reliable, efficient for aluminum tubes | Slower, aesthetic quality may be lower |

| Ultrasonic Sealing | Precise, minimal wear, ideal for small runs | Slower, less polished seals |

| Hot Jaw Sealing | Simple, low-cost, easy to set up | Slower, less visually appealing |

| Metal Tube Sealing | Strong, durable, best for metal tubes | More complex, requires specific equipment |

Hot Air Sealing: Versatile and Fast Sealing for Various Materials

How Hot Air Sealing Works

Hot air sealing works by directing heated air onto the opening of a tube, which softens the material, such as plastic or laminate. This causes the material to fuse together under pressure, creating a strong, durable bond. The method is widely used for tubes made from materials like polyethylene, polypropylene, and aluminum laminated tubes. It offers versatility, making it a popular choice in various industries, from cosmetics to food packaging.

Advantages of Hot Air Sealing

Hot air sealing is known for its fast sealing capabilities, which makes it ideal for high-volume production environments. It’s also highly versatile, working with a wide range of tube materials. The seals produced by this method are robust and secure, ensuring that the contents of the tube are well-protected and safe from external contamination. Additionally, the process is neat, providing a professional finish that enhances the overall appearance of the packaging.

Another advantage is its ease of integration into automated production lines. The speed at which the sealing occurs allows for consistent output, improving overall operational efficiency. This makes it a preferred choice for businesses that require fast, reliable results.

Disadvantages of Hot Air Sealing

While hot air sealing has many advantages, it is not without its challenges. A major drawback is the need for specialized equipment to accommodate different tube sizes. This may require frequent adjustments and the use of additional change parts, which can result in downtime and increased maintenance costs. This is particularly relevant in high-volume production environments where tube sizes may vary frequently.

The equipment can also be costly to maintain. The high-speed nature of the process can lead to wear and tear, necessitating regular servicing to ensure optimal performance. For businesses that are looking to minimize maintenance costs, this could be a concern.

High-Frequency Sealing: Effective for Aluminum Laminate Tubes

How High-Frequency Sealing Works

High-frequency sealing uses electromagnetic waves to generate heat within the tube's material. The electromagnetic field targets the tube’s seams, causing the material to bond tightly without requiring direct contact. This process is ideal for aluminum laminate tubes, which are often used in the packaging of cosmetics, pharmaceuticals, and other premium products. The process ensures that the seal is secure and that the contents remain safe from external contaminants.

Advantages of High-Frequency Sealing

High-frequency sealing is especially effective for aluminum laminate tubes, providing a strong and reliable seal that protects the product from air, moisture, and other environmental factors. It’s efficient and allows for automated production, which can lead to faster output in high-volume environments. The process produces high-quality seals, ensuring that the product remains fresh and intact throughout its lifecycle.

Moreover, this sealing technique is highly efficient for businesses focused on premium packaging. The consistency and strength of the seal contribute to the overall integrity of the product, enhancing consumer trust in the brand.

Disadvantages of High-Frequency Sealing

However, high-frequency sealing does come with some drawbacks. One of the primary disadvantages is the slower sealing process compared to hot air sealing. This can be a limiting factor for businesses with large-scale production needs. The slower speed may also result in a higher cost per unit, which could affect profitability in high-volume settings.

Additionally, while high-frequency sealing offers a strong seal, the aesthetic quality may not always meet the high standards of other sealing methods. This could impact consumer perception, especially for premium products that rely on polished, attractive packaging.

Ultrasonic Sealing: High-Precision Sealing with Less Wear and Tear

How Ultrasonic Sealing Works

Ultrasonic sealing uses high-frequency sound waves to generate vibrations within the tube’s material. These vibrations produce heat, causing the material at the tube's opening to melt and bond. The ultrasonic process requires less heat than other methods, making it ideal for sensitive products that could be damaged by excessive temperatures. This method is particularly effective for sealing tubes that contain volatile or heat-sensitive contents, such as in the pharmaceutical and cosmetic industries.

Advantages of Ultrasonic Sealing

One of the key advantages of ultrasonic sealing is its precision. The vibrations generated during the process create a highly accurate and clean seal, ensuring minimal contamination. Ultrasonic sealing also causes less wear on equipment compared to methods that involve higher temperatures. The process is more energy-efficient, requiring less power to operate, which can help reduce operational costs.

Because it generates less heat, ultrasonic sealing is perfect for smaller production runs and for products that require a higher degree of protection from heat. It also reduces the need for frequent replacement parts, which can be an ongoing cost in other sealing methods.

Disadvantages of Ultrasonic Sealing

Despite its advantages, ultrasonic sealing is slower than hot air or high-frequency sealing. The slower speed can be a disadvantage for businesses that require fast production cycles and larger quantities of sealed tubes. Additionally, the appearance of the seal may not be as visually appealing as those created by other sealing methods. This can be a concern for businesses that prioritize the aesthetics of their product packaging.

Hot Jaw Sealing: Cost-Effective Sealing for Small-Scale Operations

How Hot Jaw Sealing Works

Hot jaw sealing involves the use of heated crimping jaws to apply pressure to the tube's opening. The jaws are heated to a specific temperature, and when they come into contact with the tube, the material at the opening melts. The heat causes the ends of the tube to fuse together under pressure, creating a secure and durable seal. This method is particularly useful for small-scale operations where cost-efficiency and simplicity are essential. It doesn’t require complex machinery or specialized expertise, making it an attractive option for startups and businesses with lower production volumes.

Advantages of Hot Jaw Sealing

One of the biggest advantages of hot jaw sealing is its simplicity and low cost. The process is easy to implement, as it requires minimal equipment and space. This makes it a great choice for small businesses or those just starting with tube sealing. Additionally, the method provides reliable seals that help secure the product and maintain its integrity. The equipment is easy to maintain, which helps reduce ongoing operational costs. Since the setup is straightforward, the method is also user-friendly, with minimal training required for operators. This simplicity makes it a practical choice for businesses that need to seal smaller batches or don’t have the resources for more advanced sealing systems.

Disadvantages of Hot Jaw Sealing

Despite its cost-effectiveness, hot jaw sealing comes with limitations. The sealing process is relatively slow compared to other methods, which can hinder scalability for larger production runs. As production volumes grow, the time needed to seal each tube can lead to inefficiencies. Additionally, the appearance of the seals produced by this method may not be as aesthetically pleasing as those from more sophisticated techniques. For consumer-facing products that require a polished and professional appearance, this could be a concern. In some cases, the visual appeal of the seal may affect the overall branding and perception of product quality.

Metal Tube Sealing: Strong Seals for Metal Packaging

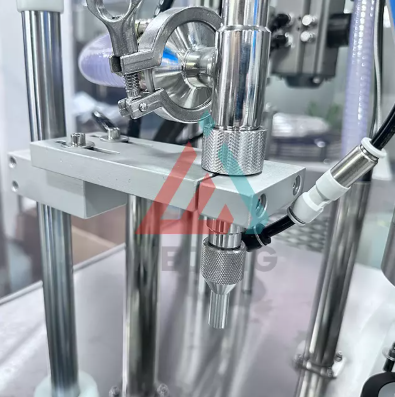

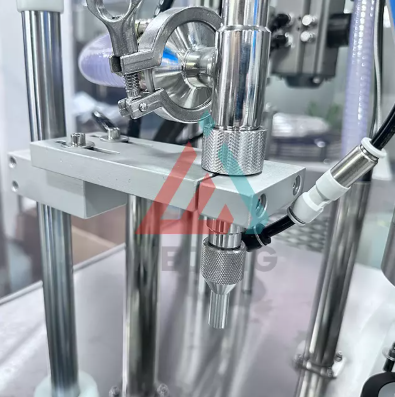

How Metal Tube Sealing Works

Metal tube sealing is typically performed using crimping stations, which fold and seal the metal tube's opening. The crimping process involves folding the tube’s open end around a metal nozzle and applying pressure to form a secure seal. This ensures that the product inside is protected from contaminants and remains securely sealed during transportation and storage. The strength of the seal is particularly beneficial for metal tubes, which are commonly used for high-value products like pharmaceuticals, luxury cosmetics, and food items that require enhanced protection.

Advantages of Metal Tube Sealing

The primary benefit of metal tube sealing is its strength. Metal tubes provide a more robust and durable seal compared to plastic alternatives, making them ideal for sensitive or high-value products. They offer superior protection against air, moisture, and contamination, which is critical for products like medications, ointments, and premium cosmetic formulations. Additionally, metal tube packaging gives products a premium look and feel, making it especially appealing for high-end consumer goods. This aesthetic advantage can be crucial in markets where presentation plays a significant role in consumer purchasing decisions. Metal tubes also have the added benefit of being tamper-proof, which enhances product safety and consumer trust.

Disadvantages of Metal Tube Sealing

While metal tube sealing offers numerous benefits, it also presents several challenges. The process is more complex than sealing plastic tubes, requiring specialized equipment for the folding and crimping process. This increases the overall cost and time needed for sealing, which can become a drawback in large-scale operations. Furthermore, the materials used for metal tubes are often more expensive than plastic, contributing to higher production costs. For businesses with limited budgets or those focused on mass production, these additional costs can be prohibitive.

Choosing the Right Tube Sealing Method for Your Business

Factors to Consider When Selecting a Sealing Method

When selecting a sealing method, it's essential to evaluate several factors to ensure you choose the most suitable one for your specific needs. First, consider the type of product you're packaging, as different sealing techniques work better with different materials. For example, hot air sealing is ideal for plastic and laminate tubes, while high-frequency sealing is typically used for aluminum laminate tubes. The material of the tube itself also plays a significant role in your decision, as some sealing methods are better suited for specific materials. For example, metal tube sealing is essential for products packaged in metal tubes, while ultrasonic sealing may be the best choice for heat-sensitive products.

Next, take into account the production volume. Some sealing methods, like hot air and high-frequency sealing, are better suited for large-scale production runs, offering fast sealing times and high efficiency. In contrast, methods like hot jaw sealing and ultrasonic sealing are more commonly used in smaller production runs or for specialized products. Understanding your production needs will help determine the most efficient and cost-effective sealing method.

How to Match the Right Sealing Method with Your Product

Matching the right sealing method to your product involves considering both the tube material and the specific requirements of the product. For example, if you’re packaging a product that is sensitive to heat, ultrasonic sealing may be the best option since it generates minimal heat. This method can help prevent product degradation during sealing. On the other hand, if you are packaging high-value items, such as luxury cosmetics or pharmaceuticals, metal tube sealing may be the ideal choice. Metal tubes provide additional protection and a premium presentation that aligns with the branding of high-end products. Additionally, for larger-scale operations that require quick sealing, hot air sealing or high-frequency sealing would be more efficient, ensuring your production process runs smoothly.

In summary, the right sealing method depends on multiple factors, including the product type, tube material, and production scale. Careful evaluation of these factors will ensure that you select the most effective sealing solution for your business’s needs.

Conclusion

Choosing the right tube sealing method is essential for optimizing your production process. Each sealing technique offers unique benefits and drawbacks, making it important to consider factors like tube material, production scale, and product needs.

Whether you're sealing plastic, laminate, or metal tubes, selecting the best technique will improve production efficiency, reduce costs, and enhance your product’s visual appeal. Guangzhou Wejing Intelligent Equipment Co., Ltd. offers advanced tube sealing solutions that provide long-lasting, reliable results for a wide range of industries, helping businesses meet high-quality standards and consumer expectations.

FAQ

Q: What is tube sealing?

A: Tube sealing is the process of securely closing the end of a tube to protect its contents from contamination or leakage. It involves using different techniques depending on the tube material and product type.

Q: What are the different types of tube sealing techniques?

A: The main types of tube sealing techniques include hot air sealing, high-frequency sealing, ultrasonic sealing, hot jaw sealing, and metal tube sealing. Each method is suited to specific materials and production needs.

Q: Why is tube sealing important?

A: Tube sealing is crucial for ensuring product safety, extending shelf life, and preventing leaks or contamination. It also plays a role in consumer perception, as a well-sealed tube often indicates a high-quality product.

Q: Which tube sealing method is best for my business?

A: The best tube sealing method depends on your production scale, tube material, and product type. For high-volume operations, hot air or high-frequency sealing might be ideal, while smaller runs may benefit from ultrasonic or hot jaw sealing.

Q: How much does tube sealing equipment cost?

A: The cost of tube sealing equipment varies widely. Automated systems like high-frequency sealing machines are more expensive, while simpler methods, such as hot jaw sealing, are more affordable. The price will also depend on production volume and customization needs.

Q: Can tube sealing be used for different materials?

A: Yes, tube sealing methods are versatile and can be used for plastic, laminate, and metal tubes. Each sealing method is designed to accommodate specific materials for optimal results.