Introduction to Aerosol Filling Machine:

Aerosol filling machine is a special filling equipment, which can be classified as liquid filling machine and gas filling machine. It is a mechanical device specially used for the production of aerosol products. The working principle of aerosol filling machine is similar to the combination of liquid filling machine and gas filling machine. The principle is to carry out liquid quantitative filling before gas filling.

Specifically, the aerosol filling machine is mainly composed of a filling system, a sealing system, a control system, etc. Among them, the filling system is responsible for filling liquid or liquefied gas into the aerosol can, the sealing system is responsible for sealing the aerosol can, and the control system is responsible for controlling and adjusting the entire filling process.

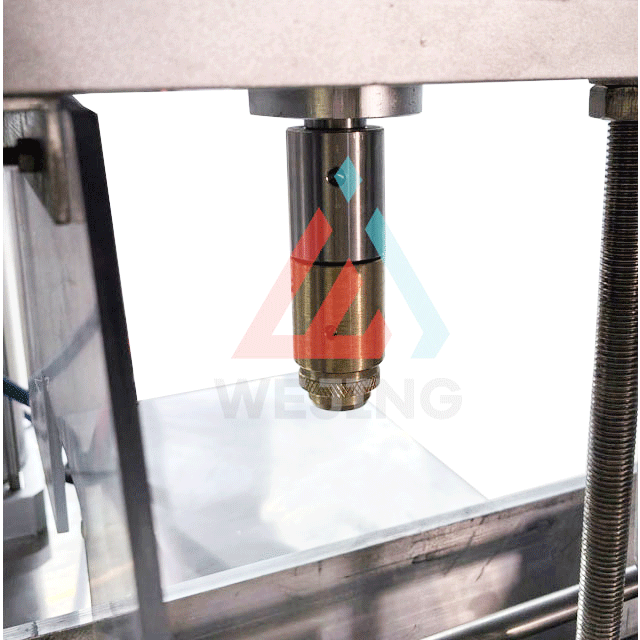

Because the aerosol product has a special reason of pressure, the filling is divided into a liquid filling machine that fills a quantitative liquid into an aerosol can at room temperature and normal pressure. The gas filling machine is to fill a quantitative and certain pressure gas (or liquefied gas) into the aerosol can. Also, because the aerosol product needs to have a certain pressure, the aerosol can must be sealed before inflation, and the gas filling machine fills gas through the valve mouth on the top of the aerosol can.

The working principle of aerosol filling machine:

The working principle of the aerosol filling machine is to fill the liquid or liquefied gas into the aerosol bottle through pressure, and then seal the aerosol bottle through the sealing device. Specifically, the aerosol filling machine is mainly composed of a filling system, a upright system, a sealing system, a Inflation system, and a control system.

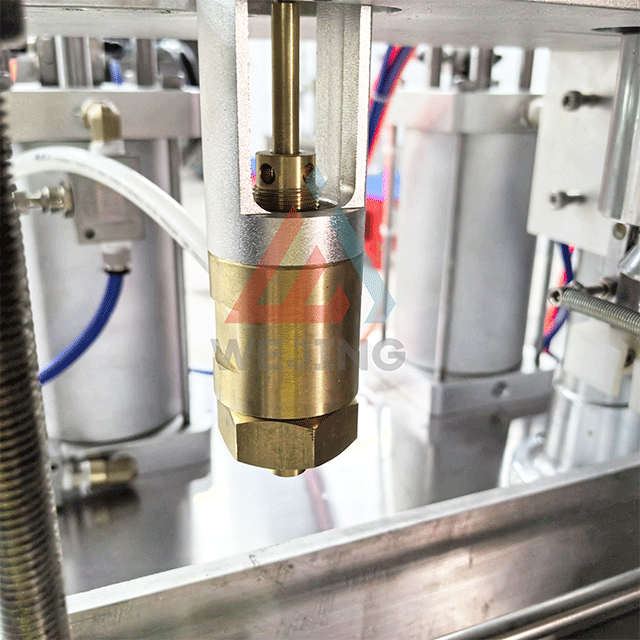

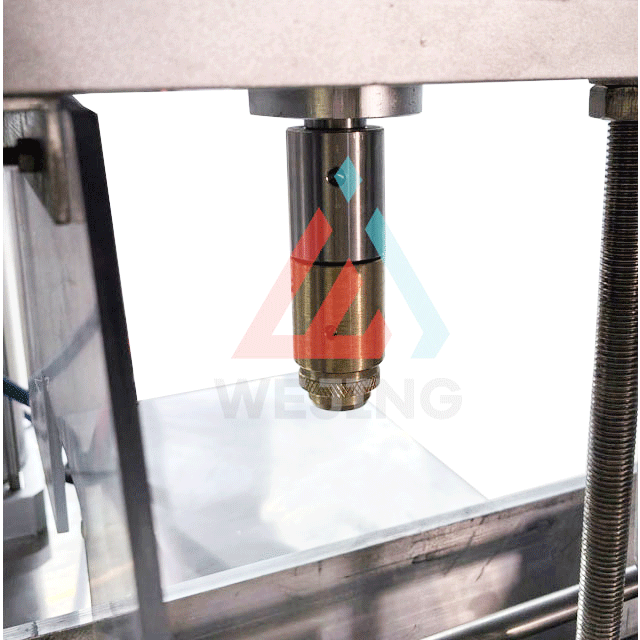

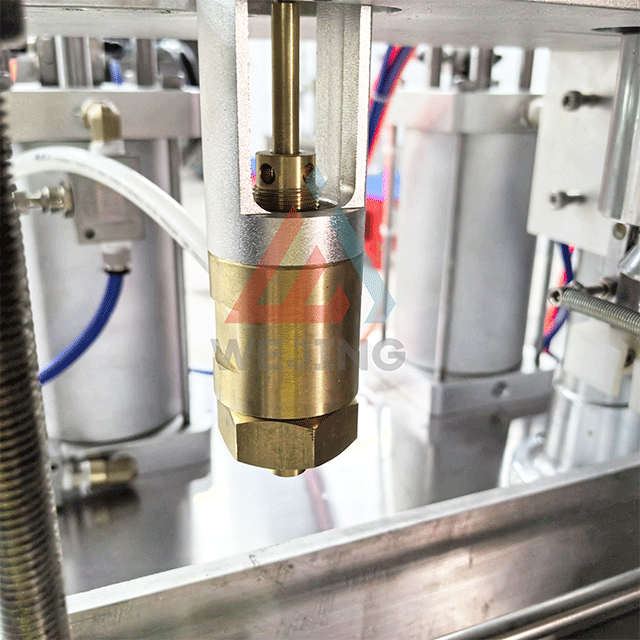

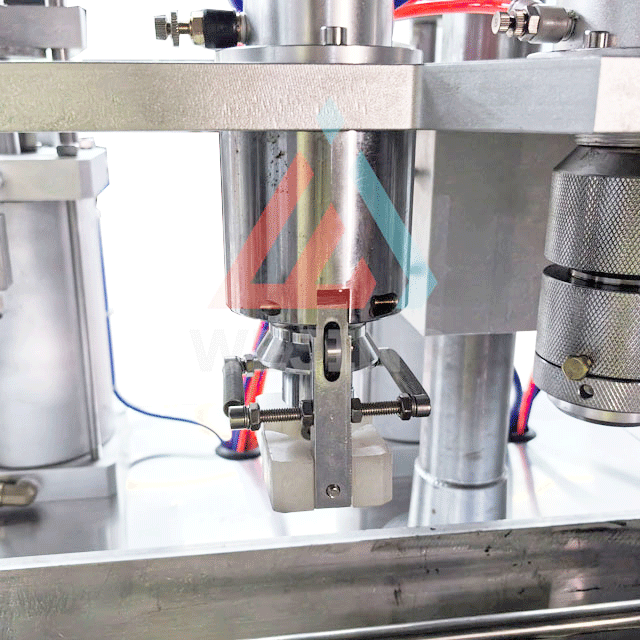

1.Filling system

Responsible for filling liquid or liquefied gas into an aerosol bottle. It is mainly composed of a liquid storage tank, a filling head, a filling pump, etc.

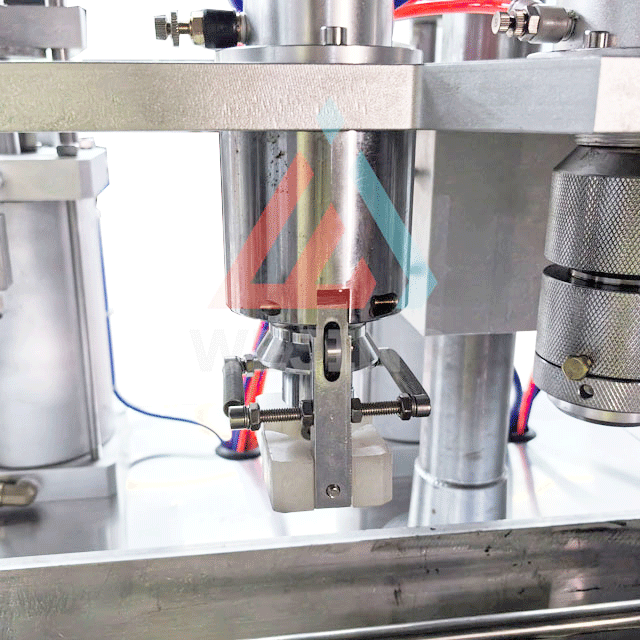

2. Upright system

Usually referring to the upper valve sealing machine in the filling process, its function is to clamp each valve back into the center of the bottle mouth to prevent the valve and bottle from being crushed during sealing.

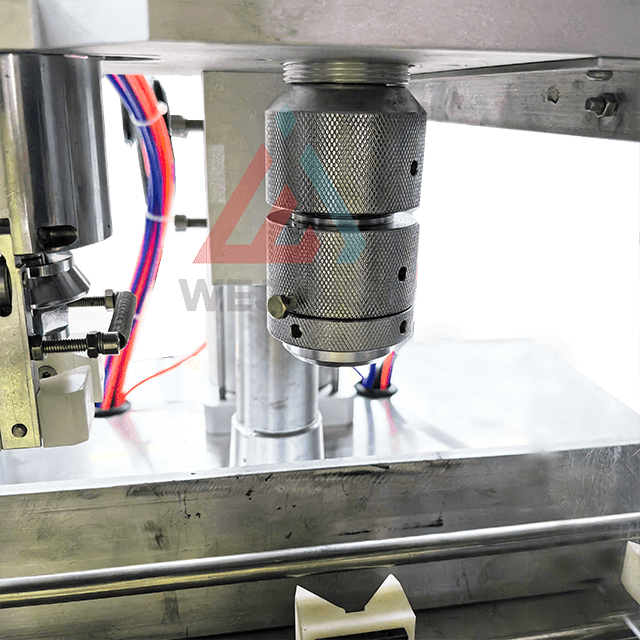

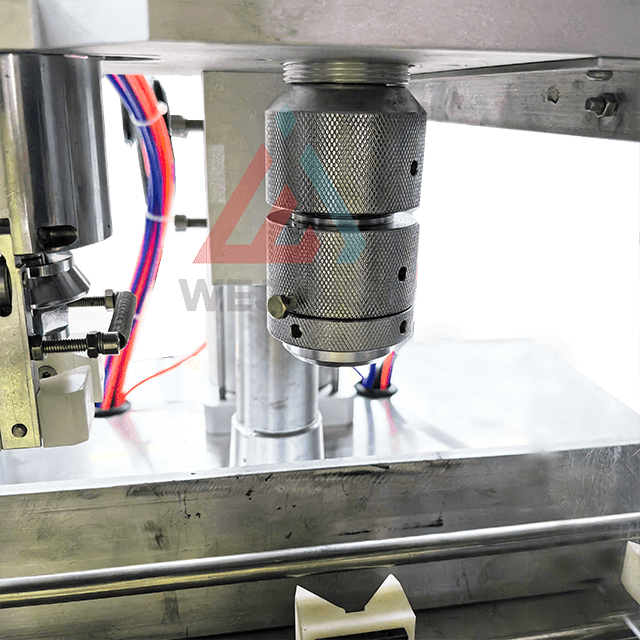

3. Sealing system

Responsible for sealing the aerosol bottle, mainly composed of a sealing head, a sealing mold, etc.

4. Inflation system

Fill the aerosol canister with propellant gas while sealing, so that the contents and propellant mix inside the canister to form an aerosol.

3. Control system

Responsible for the control and adjustment of the entire filling process, mainly composed of electrical control components, human-machine interface, etc.

The classification of aerosol filling machines:

Aerosol filling machines are divided into fully automatic aerosol filling machines and semi-automatic aerosol filling machines. So, what is the difference between them?

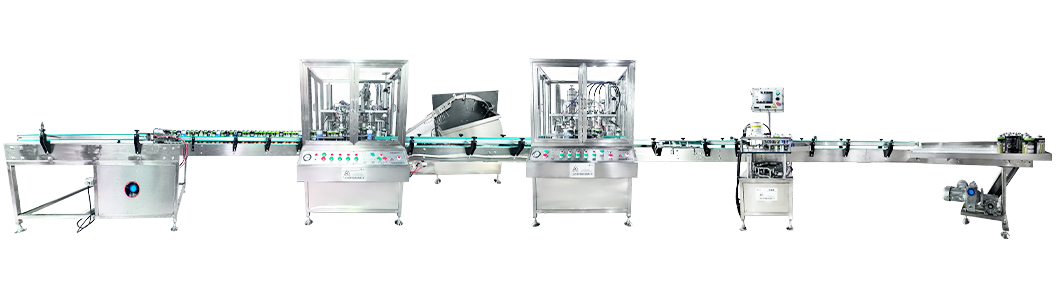

Fully automatic aerosol filling machine introduction:

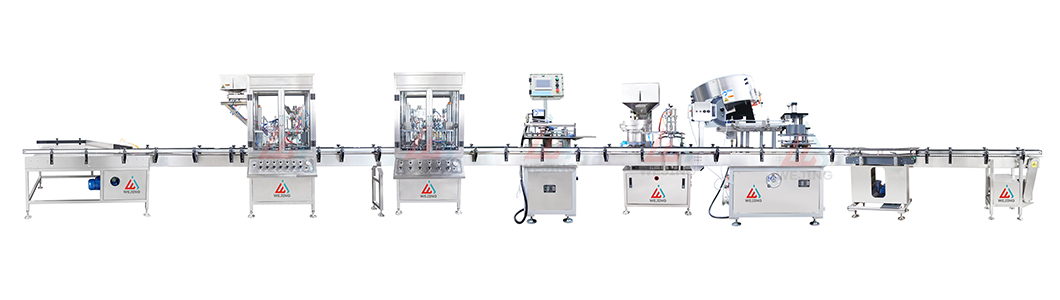

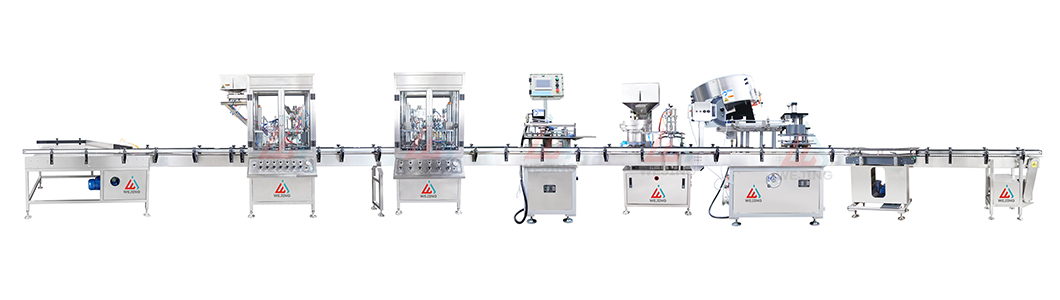

The fully automatic aerosol filling machine is a fully automatic production line composed of a bottle cleaning workbench, a fully automatic filling machine, an automatic valve machine, an automatic sealing and inflating machine, an automatic weighing and rejection machine, a water leakage detection, an automatic nozzle machine, and a large cap machine. In addition, it can be equipped with an automatic glass bead machine, a labeling machine, and a labeling machine according to needs. The conveying system can be designed in a U-shaped rotary structure to save space.

The production line has the following characteristics:

1. High degree of automation:

The production line is easy to operate, runs stably, and can effectively reduce enterprise costs and improve production efficiency.

2. Stand-alone independence:

Each stand-alone machine can complete its work independently, with an independent operating system and CNC display and other electrical components to control and adjust parameters.

3. Good coordination:

The quick linkage and separation of each stand-alone machine are fast, and the adjustment is quick and simple, making every process of production can maintain coordination.

4. Filling flexibility:

Each stand-alone machine can adapt to the filling of various cans, and the adjustment parts are few.

5. Patents and certifications:

The production line has obtained multiple national patents and passed the CE certification.

6. Diversity of combinations:

The production line runs smoothly, and the functional combinations are convenient, which is convenient for maintenance. It can be combined according to the process requirements of users' respective products.

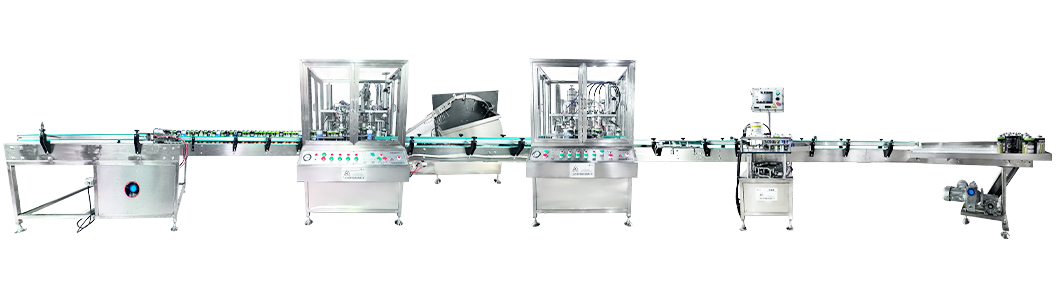

Semi-automatic aerosol filling machine introduction:

The semi-automatic aerosol filling machine is composed of a liquid filling machine, a sealing machine, and a gas filling machine. It can be operated on one or more workbenches, and it is controlled by 1 to 3 people to complete the filling, sealing, and inflating three processes, and other processes are completed by manual work.

The filling machine has the following characteristics:

1. Pure pneumatic:

Using compressed air as power, it is suitable for environments with explosion-proof requirements and has high safety.

2. No electricity:

There will be no static electricity and electric shock, and there is no need to ground.

3. Strong controllability:

In case of an emergency, the pneumatic switch can be turned off to stop the operation of the equipment.

4. Few people:

The whole line is coordinated and controlled, and only 1 to 2 people are required to operate.

5. Easy to operate:

The whole line adopts a humanized design, is easy to operate, and can be easily mastered after simple training.

6. Easy maintenance:

The structure adopts easy-to-install and disassemble structures, which are convenient for maintenance and repair.

7. Small footprint:

One workbench is enough to meet production needs, without the need for a large factory.

The application fields of aerosol filling machines:

Aerosol products are usually packaged in aerosol cans, which are popular among the masses because of their portability and ease of use. Now, with the continuous improvement and advancement of aerosol technology, aerosol filling machines are widely used in various fields.

1. Daily care products:

Common daily spray products include hair moisturizer, sunscreen lotion, perfume, shaving foam, etc. They are usually applied to the human body surface through spraying or smearing to achieve whitening, sun protection, moisturizing, cleaning, beauty, and odor removal effects.

2. Industrial and chemical products:

Aerosol filling machines can be used for filling various chemical products, such as spray paint, mold release agent, silicon-based lubricant, foaming adhesive, etc.

3. Automotive supplies:

With the continuous development of the social economy, the use of automobiles has become more and more common, and the corresponding automotive care products have also increased. Common products include car dashboard wax, carburetor cleaner, rust preventive lubricant, screw loosening agent, glass water, car wash liquid, etc.

4. Food and pharmaceutical products:

Common products include Yunnan Baiyao, salbutamol inhaler, edible seasoning spray, etc.

Conclusion:

In conclusion, different types of aerosol filling machines are suitable for different aerosol products and production needs. Aerosol filling machines are very important packaging equipment and are widely used in various fields. With the continuous development of technology, the technology of aerosol filling machines is also constantly updated and improved, and in the future, it will become more intelligent, efficient, and environmentally friendly.