In the increasingly competitive cosmetic packaging industry, efficient and precise filling machines and other related equipemnts, such as labeling machines play a vital role. Liquid Filling machines and cream & paste filling machines can not only improve production efficiency and reduce labor costs, but also ensure the consistency of product quality.

In this blog, we will introduce these key equipments used in cosmetic packaging and their advantages and features.

Process of Cosmetic Packaging

Cosmetic filling is the key process of packaging cosmetic raw materials into containers. According to the characteristics of the product, you need to choose the right filling equipment: Liquid Filling Machine is suitable for water, lotion and other liquid products, cream filling machine is used for viscous cream, hair wax and other products.

Preparation for Filling

Material inspection using an in-line weighing system

Cleanliness check of the container

Setting up the filling parameters and the automatic feeding system

Confirm the readiness of subsequent equipment such as the Bottle Labeling Machine.

Filling Procedure

Liquid product filling

Adopt a fully automatic liquid filling machine for quantitative filling.

Equipped with anti-drip filling valve to avoid product waste.

Filling volume is precisely controlled by servo motor.

Filling accuracy is monitored in real time (±1%).

Paste/Cream filling

Use piston type paste filling machine for filling.

Equipped with a heating system to control product fluidity

Positive pressure filling to prevent air bubbles

Automatic adjustment of filling speed and pressure

Packaging process

Capping with automatic capping machine

Labeling is done by labeling machine.

Laser coding machine to print the date of production

Packaging is done by automatic cartoning.

Quality control measures

In-line check weighing system for real-time monitoring of filling quantity

Visual inspection system to control the appearance quality

CIP cleaning system ensures equipment hygiene

Centralized control system to record production data

Liquid filling machine

Definition and application of liquid filling machine

Liquid filling machine is a kind of equipment specially used to fill liquid products into containers. In the cosmetics industry, liquid filling machines are widely used in the packaging of various liquid products, such as lotions, shampoos, etc.

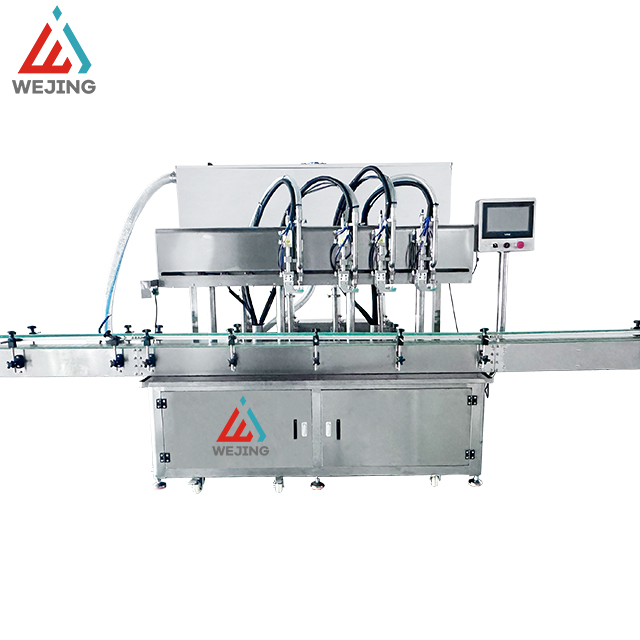

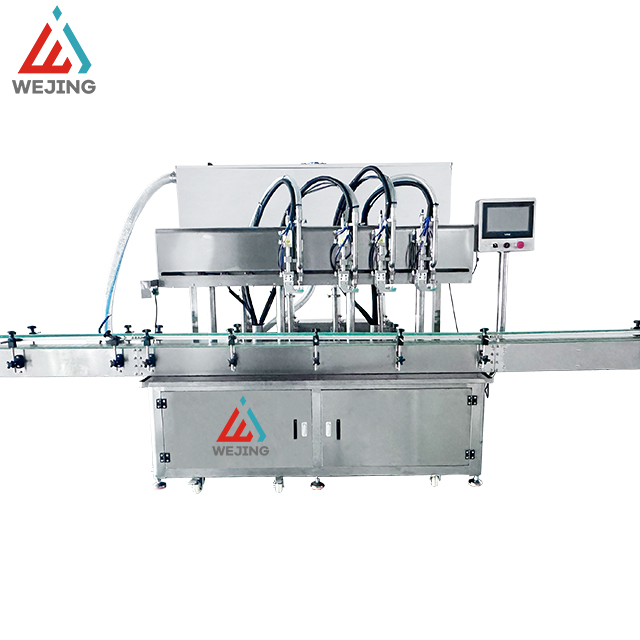

Wejing's liquid filling machines

Wejing Company provides a variety of high-performance liquid filling machines to meet the needs of different customers. These filling machines have the following main features and advantages:

Automatic Liquid Filling Machine of Wejing

Compact design and beautiful appearance: Weijing's liquid filling machine adopts a reasonable compact design, which not only saves production space, but also has a beautiful appearance, which enhances the overall image of the production workshop.

Adopting international famous brand electrical components: In order to ensure the reliability and stability of the equipment, Weijing selected internationally renowned brands of electrical components, such as double-acting cylinders and magnetic switches from FESTO, Germany, PLC computers from Mitsubishi, Japan, photoelectric sensors from Omron, and touch screens from Siemens, Germany, etc., to ensure the long-term and stable operation of the equipment.

High filling accuracy, up to ±1%: Accurate filling volume control is one of the key indicators of liquid filling machines. Weijing's liquid filling machines use advanced metering systems such as magnetic flowmeters, mass flowmeters, etc., which can achieve high-precision filling of ±1%, ensuring consistent product volume in each container.

Fast filling speed, up to 600-1000 bottles/hour: Weijing's liquid filling machine adopts a multi-head parallel filling design, which can fill multiple containers at the same time, greatly improving production efficiency. Depending on the machine model and configuration, the filling speed can reach 600-1000 bottles per hour to meet the needs of mass production.

Strong applicability: Suitable for various cosmetic liquids, such as lotions, lotions, essences, etc. By replacing different filling nozzles and adjusting filling parameters, it can adapt to liquid products with different viscosities and characteristics.

Advantages of using Wejing liquid filling machine

Easy maintenance, disassembly and cleaning without tools: The design of Weijing liquid filling machine is very user-friendly, and it can be easily disassembled and cleaned without any tools, which greatly simplifies the process of equipment maintenance. The filling system adopts a clamp-type quick-release sanitary joint, and the entire cylinder can be quickly disassembled from top to bottom, which is convenient and thorough cleaning.

Accurate filling to avoid product waste: Weijing liquid filling machine is equipped with a precise metering and adjustment system, which can accurately control the filling volume through a combination of large-scale adjustment and fine-tuning. At the same time, the equipment also has the function of not filling when there is no bottle or lack of bottle, which avoids product waste.

High efficiency and productivity: The fast filling speed can significantly improve production efficiency, reduce production time and labor costs, and improve overall productivity.

Simple structure, easy operation and maintenance: Weijing liquid filling machine adopts a simple and clear structural design, operators can quickly get started, and daily maintenance is also very convenient.

Paste/Cream filling machine

Definition

Apart from luqiud filling machines, paste filling machines are also commonly used in cosmetic packaging. Paste filling machine is a specialized equipment for filling paste and ointment products into various containers. It has a wide range of applications in cosmetic, pharmaceutical, food and other industries. It can accurately fill various semi-solid or creamy products such as face cream, hand cream, petroleum jelly, etc. into bottles, jars, tubes and other packages.

Advantages compared to manual canning

Compared with traditional manual filling, the use of automated cream filling machine can significantly improve the productivity and filling accuracy, and ensure the consistency of product quality. Advanced paste filling machine usually adopts servo motor control to realize accurate quantitative filling; equipped with heating device, which can be adapted to different viscosity products; at the same time, it has the functions of automatic loading and conveying to realize fully automatic production.

The main features and advantages of Wejing's paste filling machines:

High-quality Paste Filling Machine

PLC control, easy and intuitive operation: through the touch screen interface, the operator can easily set and adjust the filling parameters.

Servo motor drive, stable and precise filling: controlled by high precision servo motor, it realizes ±1% filling precision to avoid overfilling or underfilling of products.

Wide range of application and high flexibility: it can fill cream products with different viscosities, and meet diversified production needs by changing filling nozzles and adjusting parameters.

High degree of automation and significant improvement of efficiency: integrated automatic feeding, conveying, filling, capping and other functions.

Bottle labeling machine

Labeling is an indispensable part of the cosmetic packaging process. Exquisite, eye-catching labels can not only display product information, but also enhance the visual appeal of the product and improve brand recognition. Bottle labeling machine is specially used to paste labels on the body of the cosmetic bottle equipment, has a wide range of applications in the cosmetics industry.

Bottle labeling machine applications

In the cosmetic industry, bottle labeling machine is mainly applied to label the following products:

Bottle products: such as lotion bottles, essence bottles, make-up bottles, etc., which can be labeled on the bottles and caps.

Canned products: such as face cream cans, eye cream cans, cream cans, etc., which can be labeled on the can body and lid.

Hose products, such as face wash hose, hand cream hose, etc., can be labeled on the hose body.

In addition, bottle labeling machine can also be applied to special shaped cosmetic packaging, such as shaped bottles, triangular bottles and so on. By changing the molds and adjusting the settings, it can be adapted to the labeling needs of different sizes and shapes.

Types of labeling machines

There are several types of common bottle labeling machines as follows:

Round Bottle Labeling Machine: specially used for labeling cylindrical bottles, such as lotion bottles, essence bottles, etc.Square bottle labeling machine: for rectangular or square bottle labeling, such as perfume bottles, nail polish bottles and so on.Irregular bottle labeling machine: it can be adapted to the labeling of irregular shaped bottles, such as shaped bottles, conical bottles and so on.Multi-surface labeling machine: can paste labels on multiple surfaces of bottles at the same time to improve labeling efficiency.

Advantages of Wejing's bottle labeling machine

Weijing's universal labeling machines has the following outstanding advantages:

Wide range of application: it can be adapted to a variety of bottle types, including round bottles, square bottles, oval bottles, etc., to meet the labeling needs of the cosmetic, daily chemical, food and other industries.

Precise labeling: Adopting imported microcomputer control system and extra-large touch screen, it is easy to operate and the labeling position is precise, which realizes high quality labeling effect.

Stable and Reliable: Made of high grade stainless steel and anodized aluminum alloy to ensure the equipment never rusts, conforms to GMP standards, and has stable and long-lasting performance.

Function of parameter memory: The equipment can store more than 100 groups of labeling parameters, which can be quickly recalled when changing products, greatly shortening the time of changeover and improving production efficiency.

Modular design: the labeling machine adopts modular design, can be flexibly matched with different functional modules to meet the individual needs of customers.

Advantages of Using Filling Machines in the Cosmetic Packaging

Using filling machines can bring many benefits to cosmetics production. These advantages make filling equipment an indispensable core equipment in modern cosmetics production, which can effectively improve production efficiency, ensure product quality and reduce production costs.

Improve production efficiency and output:

High-speed fully automatic production line can achieve a filling speed of 130-150 bottles/minute

Equipped with automatic bottle feeding system to ensure continuous operation of the production line

One-button lifting function greatly improves the speed of production and mold change

Adopting turntable design, multiple heads can be filled at the same time

Suitable for tinplate, aluminum cans and other packaging forms with 1-inch can mouth specifications

Consistent and accurate product filling:

Using PLC program control and touch screen human-machine interface (HMI) technology

Repeat filling accuracy reaches the industry-leading level of ±1%

With an online weighing detection function to ensure the accuracy of each bottle's weight

Filling capacity range 10-1200ml to meet different product needs

Equipped with high-precision electronic weighing system, weighing accuracy of ±1.5g

Reduce labor costs and human errors:

Fully automated operation to minimize human intervention

With automatic detection function, it can identify missing bottles and not fill

Automatic water full shutdown, waterless startup, no manual supervision required

IC microcomputer controller automatically flushes reverse osmosis membrane

Integrated design, integrating filling, sealing, inflation and other functions

Improve product quality and shelf life:

All parts in contact with materials are made of 316L grade stainless steel

Pipes and tanks are mirror polished to meet GMP requirements

Adopt gas-electric safety grade explosion-proof design

Applicable to a variety of medium-viscosity materials such as oil, water, emulsion, etc.

Equipped with an efficient cleaning system to ensure equipment hygiene

Enhance hygiene and pollution control:

Adopt quick-install sanitary connectors for easy disassembly and cleaning

The entire cylinder can be easily disassembled and cleaned without tools

The surface roughness of key components is controlled below 0.8

Equipped with sterile sampling ports and CIP cleaning spray heads

Meet the quality management system requirements of the international ISO9001 standard

Contact Wejing For Your Need

This blog comprehensively explains the key role of filling equipment in modern cosmetics production, and introduces in detail the technical characteristics and application advantages of core equipment such as liquid filling machines, paste filling machines and labeling machines. For cosmetics packaging, it is particularly important to choose the right high-quality machine.

With advanced technical strength, reliable product quality and professional service system, Wejing's filling equipment has become an ideal choice for cosmetics companies to improve production efficiency and ensure product quality. Whether it is a large-scale automated production line or small and medium-sized production needs, Wejing can provide the most suitable solution. Don't hesitate, contact us now!