Selecting the right cosmetic filling machine is crucial to ensure efficient production, consistent product quality, and customer satisfaction. With a wide range of cosmetic products, from lightweight lotions to thick creams and powders, cosmetic manufacturers must choose a filling machine that can handle their diverse product portfolio.

This blog will guide you through the process of selecting the optimal cosmetic filling equipment for your various products, taking into account factors such as product characteristics, filling accuracy, versatility, and manufacturer expertise.

Understanding Your Cosmetic Product Portfolio for Filling Machine Selection

The first step in choosing a cosmetic filling machine is to thoroughly understand your product portfolio. Classify your cosmetic products based on their viscosity, texture, and other unique characteristics. For instance, you may have low-viscosity serums, medium-viscosity lotions, and high-viscosity creams. Additionally, consider any products with special requirements, such as those containing particulates or temperature-sensitive ingredients.

| Product Type | Viscosity Range (cP) | Examples |

| Low | 1-500 | Serums, toners, essences |

| Medium | 500-5,000 | Lotions, light creams |

| High | 5,000-50,000+ | Thick creams, gels, pastes |

Table 1: Product viscosity ranges and examples

By categorizing your cosmetic products, you can better determine the filling accuracy and precision required for each type. For example, low-viscosity serums may require a filling accuracy of ±0.5%, while high-viscosity creams may allow for a slightly wider tolerance of ±1%.

Matching Filling Machine Types to Product Characteristics

Choosing the right cosmetic filling machine requires careful matching of the machine type to your products' specific characteristics. This ensures optimal performance, accuracy, and efficiency in the filling process. Let's explore the three main types of filling machines and their suitability for various product characteristics.

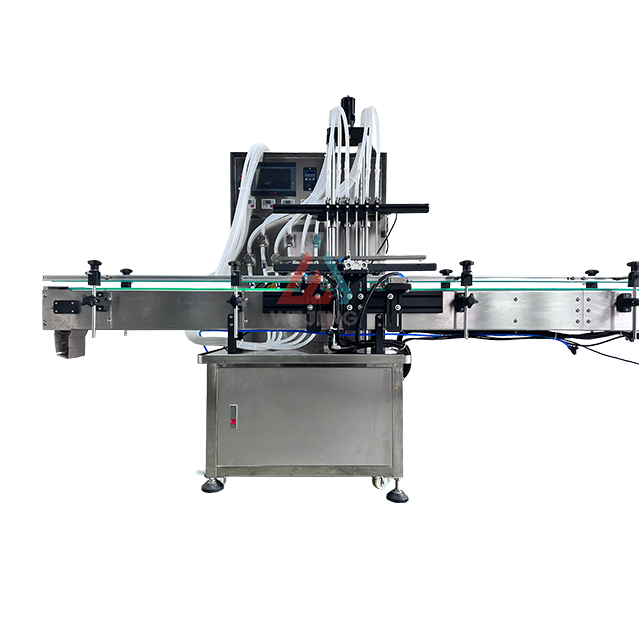

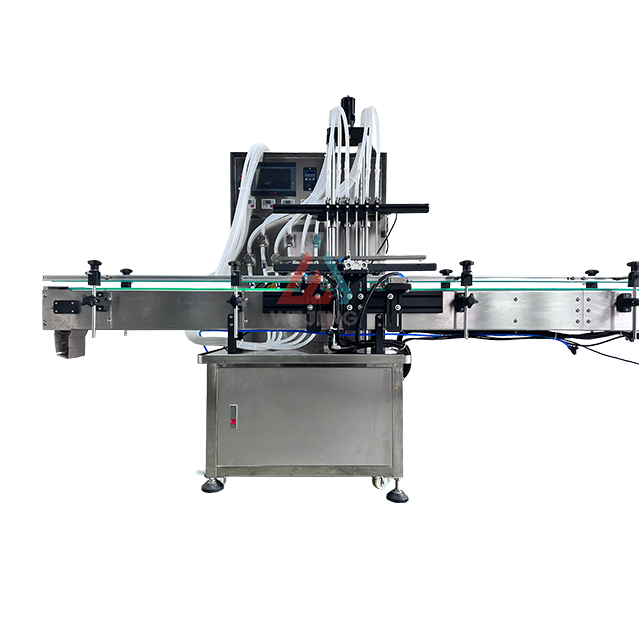

Liquid Filling Machines for Low to High Viscosity Products

Liquid filling machines are designed to handle products with a wide range of viscosities, from low to high. These machines are further categorized based on their filling principles and the viscosity range they can accommodate.

| Liquid Filling Machine Type | Viscosity Range (cP) | Suitable Products |

| Gravity Fillers | 1-500 | Water, alcohol, thin lotions |

| Pressure Fillers | 500-5,000 | Shampoos, conditioners, shower gels |

| Piston Fillers | 500-10,000+ | Creams, gels, pastes |

Table 2: Liquid filling machine types and their suitable viscosity ranges

Gravity Fillers: These machines rely on the force of gravity to dispense low-viscosity liquids, making them ideal for products like toners, essences, and thin serums.

Pressure Fillers: Using pressure to dispense liquids, these machines can handle a wider range of viscosities, including shampoos, conditioners, and body washes.

Piston Fillers: For high-viscosity liquids and semi-solids, piston fillers offer precise dosing and exceptional accuracy. They are well-suited for products like hair masks, styling gels, and thick serums.

Paste Filling Machines for Thick and Semi-Solid Products

Paste filling machines are engineered to handle thick, semi-solid products that require more powerful and specialized filling mechanisms.

| Paste Filling Machine Type | Viscosity Range (cP) | Suitable Products |

| Piston Fillers | 5,000-100,000+ | Thick creams, ointments, balms |

| Auger Fillers | 10,000-500,000+ | Pastes, gels, putties |

Table 3: Paste filling machine types and their suitable viscosity ranges

Piston Fillers: With their ability to handle high-viscosity products, piston fillers are a popular choice for thick creams, ointments, and balms. They offer excellent accuracy and consistency in dosing.

Auger Fillers: For extremely thick and dense products, auger fillers use a rotating screw to dispense the product. They are ideal for pastes, gels, and putties that require a high level of control and precision.

Powder Filling Machines for Dry and Granular Products

Powder filling machines are specifically designed to handle dry, granular, and free-flowing products. These machines ensure accurate and consistent dosing of powders while minimizing dust and product waste.

| Powder Filling Machine Type | Particle Size Range (μm) | Suitable Products |

| Auger Fillers | 50-1,000 | Fine powders, spices, supplements |

| Cup Fillers | 500-5,000 | Coarse powders, salts, exfoliants |

Table 4: Powder filling machine types and their suitable particle size ranges

Auger Fillers: Using a rotating auger, these machines accurately dispense fine powders, such as setting powders, spices, and dietary supplements.

Cup Fillers: For coarser powders and granules, cup fillers use a volumetric cup to measure and dispense the product. They are well-suited for products like bath salts, body scrubs, and exfoliating powders.

Considerations for Product Particle Size and Temperature Sensitivity

In addition to viscosity, product particle size and temperature sensitivity should be considered when selecting a filling machine.

Particle Size: For products containing particulates, such as exfoliating scrubs or glitter-infused formulas, choose a filling machine with nozzles and pumps that can handle the specific particle size without clogging or damaging the product.

Temperature Sensitivity: Some cosmetic products, like those containing heat-sensitive ingredients or formulations that thicken at low temperatures, may require temperature control during the filling process. In such cases, opt for filling machines equipped with jacketed tanks, temperature sensors, and heating or cooling systems to maintain the desired product temperature.

Evaluating Versatility and Adaptability of the Filling Machine

When investing in a cosmetic filling machine, it's essential to consider its versatility and adaptability to accommodate your current and future product range. A flexible filling machine can handle various product types, packaging formats, and production requirements, saving you time and resources in the long run.

Importance of Machine Flexibility for Handling Various Products

A versatile cosmetic filling machine should be capable of handling a wide range of product viscosities, from thin liquids to thick pastes and powders. This flexibility allows you to streamline your production process and minimize the need for multiple specialized machines.

Look for filling machines with adjustable settings, such as:

Customizable filling speeds

Adjustable nozzle sizes

Interchangeable product pathways

Programmable recipes for different product types

Quick Changeover Capabilities for Minimizing Downtime Between Products

In a fast-paced production environment, the ability to quickly switch between different products and packaging formats is crucial. A filling machine with quick changeover capabilities can significantly reduce downtime and increase overall productivity.

Some key features to look for include:

Tool-free changeovers

Color-coded parts for easy identification

Pre-programmed settings for different products

Automated cleaning and sanitizing systems

By minimizing changeover times, you can optimize your production schedule, reduce product waste, and improve overall equipment effectiveness (OEE).

Modular Design Options for Future Expandability and Upgrades

As your business grows and evolves, your filling equipment should be able to adapt to your changing needs. A modular filling machine design allows for easy expandability and upgrades, ensuring that your investment can keep pace with your business.

Consider machines with:

Scalable frame designs

Plug-and-play components

Upgradeable software and control systems

Compatibility with various filling technologies (e.g., volumetric, net weight, flow meters)

Compatibility with Different Packaging Types and Materials

A versatile cosmetic filling machine should be compatible with a wide range of packaging types and materials to accommodate your diverse product range. This compatibility ensures that you can use the same machine for multiple products, reducing the need for separate filling lines.

Look for machines that can handle:

Various container shapes and sizes (e.g., bottles, jars, tubes)

Different closure types (e.g., pumps, sprays, droppers)

Multiple packaging materials (e.g., glass, plastic, metal)

Specialized packaging features (e.g., airless, double-walled)

| Packaging Type | Compatible Filling Machine Features |

| Bottles | Adjustable nozzles, variable speed conveyor, neck-grabbing clamps |

| Jars | Diving nozzles, bottom-up filling, vacuum assist |

| Tubes | Positive displacement pumps, servo-driven pistons, hot air sealing |

| Airless | Specialized nozzles, vacuum-assisted filling, crimp or snap-on capping |

Table 5: Packaging types and compatible filling machine features

Ensuring Optimal Performance for Each Product Type

To achieve the best results and maintain product quality, it's crucial to select a cosmetic filling machine that offers optimal performance for each product type. By considering adjustable filling parameters, product-specific tooling, cleanability, and gentle handling options, you can ensure that your filling machine meets the unique requirements of your diverse product range.

Adjustable Filling Parameters for Fine-Tuning Accuracy and Precision

A versatile cosmetic filling machine should offer adjustable filling parameters to accommodate the specific characteristics of each product type. Fine-tuning these parameters allows you to achieve the desired accuracy and precision, minimizing product waste and ensuring consistent fill levels.

Key adjustable parameters include:

Fill volume: Precise control over the amount of product dispensed per container

Fill speed: Adjustable speed settings to optimize filling efficiency and prevent product splashing or foaming

Nozzle height: Adjustable nozzle positioning to accommodate different container sizes and minimize product dripping

Pressure settings: Customizable pressure control for consistent filling of viscous or sensitive products

By having the ability to fine-tune these parameters, you can adapt your filling machine to handle a wide range of product viscosities, densities, and flow characteristics, ensuring optimal performance across your product portfolio.

Product-Specific Tooling and Accessories for Improved Efficiency

Investing in product-specific tooling and accessories can be of vital importance. These specialized components are designed to handle the unique properties of different product types, such as viscosity, particle size, and flow behavior.

Examples of product-specific tooling and accessories include:

Nozzles: Various nozzle designs (e.g., cone-shaped, multi-port, hypodermic) for precise filling of liquids, pastes, and powders

Pistons: Different piston materials (e.g., stainless steel, ceramic, PTFE-coated) for compatibility with a range of product formulations

Hoppers and agitators: Customized hoppers and agitation systems for consistent feeding of powders and granular products

Heating or cooling jackets: Temperature control accessories for maintaining product stability during the filling process

| Product Type | Recommended Tooling and Accessories |

| Low-viscosity liquids | Cone-shaped nozzles, positive displacement pumps, overflow filling |

| High-viscosity pastes | Piston fillers with PTFE-coated pistons, gear pumps, follower plates |

| Powders and granules | Auger fillers, vibrating hoppers, agitators, dust collection systems |

| Temperature-sensitive products | Jacketed hoppers, temperature sensors, heating/cooling control systems |

Table 6: Product types and recommended tooling and accessories

Cleanability and Sanitation Features for Maintaining Product Integrity

Maintaining product integrity is paramount in the cosmetic industry. A filling machine with excellent cleanability and sanitation features ensures that your products remain free from contamination and meet the highest quality standards.

Look for machines with:

Stainless steel construction: Durable, corrosion-resistant, and easy to clean and sanitize

Hygienic design: Smooth surfaces, minimal crevices, and easy-to-disassemble components for thorough cleaning

CIP/SIP capabilities: Clean-in-place and sterilize-in-place systems for efficient and effective sanitation between product runs

FDA-compliant materials: Food-grade components and lubricants that meet regulatory requirements for cosmetic production

By prioritizing cleanability and sanitation features, you can minimize the risk of cross-contamination, extend product shelf life, and maintain the integrity of your cosmetic formulations.

Gentle Handling Options for Delicate or Sensitive Products

Some cosmetic products, such as emulsions, suspensions, or products containing delicate ingredients, require gentle handling during the filling process to maintain their stability and effectiveness. A filling machine with gentle handling options can prevent product degradation and ensure consistent quality.

Gentle handling options include:

Low-shear pumps: Peristaltic or diaphragm pumps that minimize product agitation and prevent ingredient separation

Bottom-up filling: Nozzles that fill containers from the bottom up, reducing air incorporation and product foaming

Vacuum-assisted filling: Systems that remove air from containers before filling, minimizing oxidation and preserving product integrity

Laminar flow nozzles: Specialized nozzles that ensure a smooth, non-turbulent product flow, preventing product damage

Consider the efficiency and productivity of cosmetic filling machines

Production capacity of cosmetic filling machines

One of the main considerations when selecting a filling machine is to ensure it has sufficient production capacity to meet your current and future demand for each product type. Evaluate your expected production volume and growth projections to select a machine that can handle the required output. Consider machines with adjustable filling speeds and fast changeover capabilities to accommodate different production requirements and maximize overall equipment effectiveness (OEE).

Factors that affect production capacity include:

Filling speed: the number of containers filled per minute

Container size: the amount of product dispensed per container

Product viscosity: the higher the viscosity, the slower the filling speed

Changeover time: the time required to switch between different products or container sizes

Balancing filling speed with accuracy and precision

While high filling speeds are desirable for increased productivity, it is critical to maintain the proper balance between speed and filling accuracy. Sacrificing accuracy for speed can result in product waste, inconsistent fill levels, and customer dissatisfaction.

Look for a filler with the following features:

Precision dosing system: Volumetric, net weight, or flow meter filling technology that ensures accurate dispensing

Adjustable speed settings: Ability to fine-tune filling speed based on product characteristics and container size

Smooth product flow: Laminar flow nozzles or gentle handling options prevent splashing or foaming, ensuring consistent fill levels

| Filling Technology | Accuracy | Speed | Applicable Products |

| Volumetric | High | Medium | Thin to Medium Viscosity Liquids |

| Net Weight | High | Low | Thick Liquids, Pastes, Powders |

| Flow Meter | Medium | High | Low to Medium Viscosity Liquids |

Table 7: Comparison of Filling Technologies Based on Accuracy and Speed

Automation Options to Reduce Labor and Increase Output

Automating your cosmetics filling process can significantly reduce labor requirements, increase output, and improve overall efficiency. Consider using a filling machine with integrated automation to streamline your production workflow. By incorporating automation into your filling process, you can minimize manual intervention, reduce the risk of human error, and increase the consistency and reliability of your production output.

Automation options include:

Automated container handling: conveyor systems, turntables, or robotic arms to move containers during the filling process

Inline capping and sealing: automated cappers or heat sealers to close containers immediately after filling

Labelers: integrated labeling systems that apply labels to filled containers, ensuring accurate product identification

Vision systems: quality control cameras to check fill levels, cap position, and label alignment, reducing the need for manual inspection

Integrate with other packaging equipment for seamless operation

For a seamless and efficient production process, it is important to consider how your cosmetics filling machine integrates with other packaging equipment. Proper integration ensures a smooth flow of containers and minimizes bottlenecks or downtime.

Key considerations for integration include:

Compatible conveyor heights: Ensure the filler’s conveyor system is at the same height as the upstream and downstream equipment

Synchronous speeds: Match the filler’s output rate to the speed of other packaging machines, such as cappers or labelers

Communication protocols: Select a filler with a compatible communication interface (e.g. Ethernet, PLC) to allow seamless data exchange with other equipment

Modular design: Select a filler with a modular layout that allows for easy integration of additional packaging modules as needed

Conclusion

Selecting the right cosmetic filling machine requires careful consideration of product characteristics, filling accuracy, production capacity, and machine versatility. From viscosity ranges to automation options, every factor plays a crucial role in achieving optimal filling performance.

As a leading manufacturer, Wejing offers comprehensive filling solutions for both liquid and cream products. Our advanced filling machines feature precision dosing systems, quick changeover capabilities, and robust automation options. Whether you need a liquid filler or cream filling machine, contact Wejing today to find the perfect solution for your cosmetic production needs.

Frequently Asked Questions About Cosmetic Filling Machines

Q: What is the filling accuracy range for a cosmetic liquid filling machine?

A: Most modern cosmetic liquid fillers achieve accuracy between ±0.5% to ±1%. High-precision models can reach ±0.2% accuracy for premium cosmetic products.

Q: Can the same filling machine handle both thin serums and thick creams?

A: While versatile machines exist, it's recommended to use dedicated fillers for different viscosity ranges. Thin serums typically require liquid fillers, while thick creams need specialized paste fillers.

Q: How long does it take to clean and sanitize a cosmetic filling machine between different products?

A: With modern CIP systems, cleaning typically takes 30-45 minutes. This includes complete product changeover and sanitization for cosmetic-grade requirements.

Q: What's the minimum production speed I should look for in a cosmetic filling machine?

A: Entry-level machines should handle at least 20-30 bottles per minute. Mid-range machines typically operate at 40-60 bottles per minute for efficient production.

Q: Do I need different nozzles for different container types?

A: Yes, different container openings and product viscosities require specific nozzle types. Most machines come with a set of interchangeable nozzles for various applications. nnnnnnnnnnnnn