In the field of mask production, emulsification of raw materials, pure water treatment and filling and packaging are the core links that determine product quality and efficiency. To meet the market demand, we provide a full set of solutions from raw material preparation to finished product packaging, covering vacuum homogenizing emulsifier, reverse osmosis water treatment system, automatic mask filling machine and other equipments, to help enterprises enhance competitiveness.

1.Homogenizing and emulsifying machine: high shear homogenizing

Emulsifying pot as the core equipment for mask liquid preparation, its material and process directly affect the stability of the finished product and equipment life.

|

(1) Material selection: 304 and 316 stainless steel (sanitary standard), suitable for high hygiene requirements of the cosmetics industry, to ensure that the raw materials are not contaminated.

(2)Multi-stage high shear homogenization: support for speed regulation in stages (such as low-speed mixing, followed by high-speed homogenization), to avoid splashing of high-viscosity raw materials, suitable for serums, gels and other formulations.

|

2.Fully automatic mask filling machine: high efficiency, precision, low consumption

For mask packaging needs, the following two star models are recommended to meet the production needs of enterprises of different sizes:

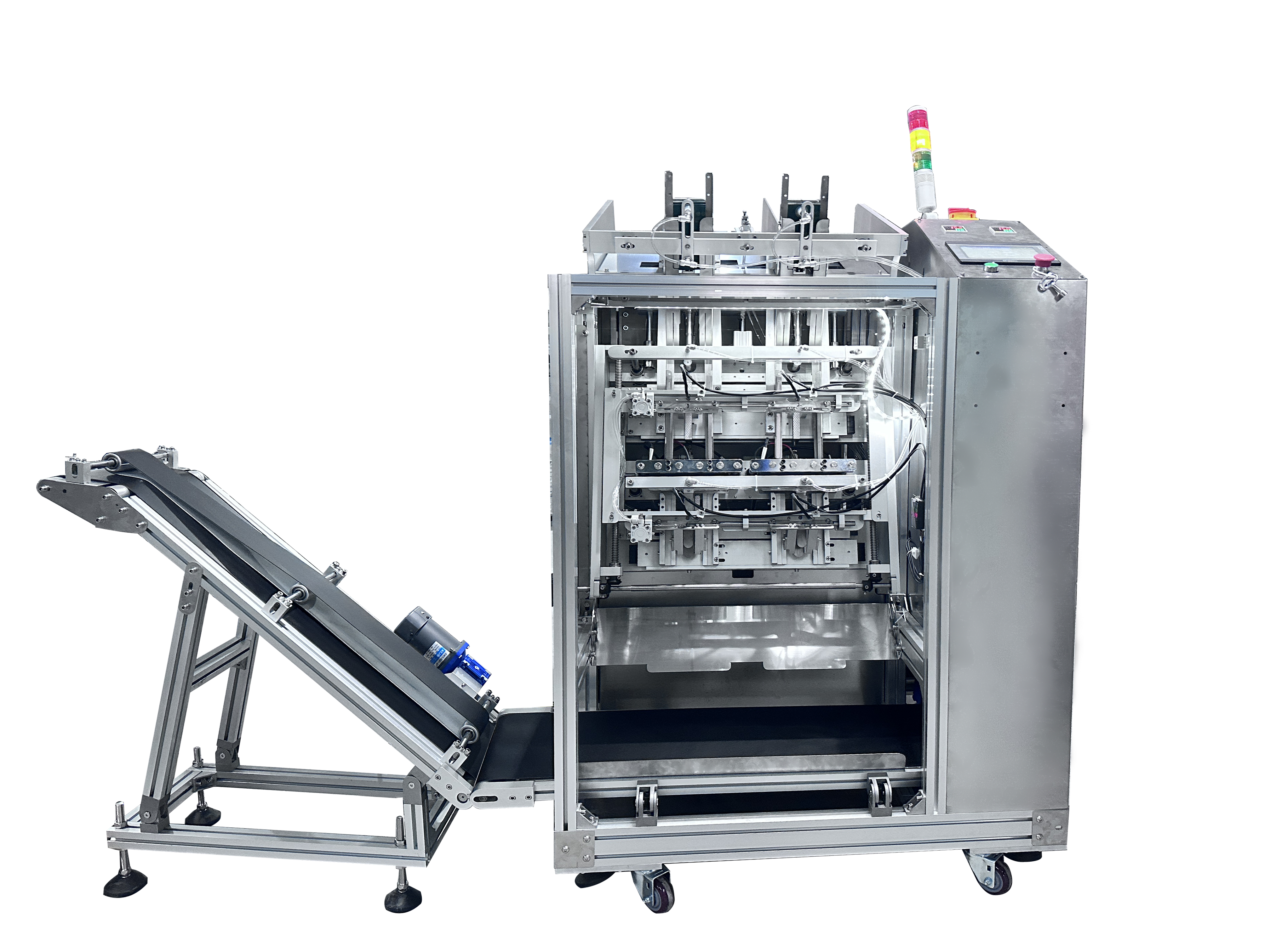

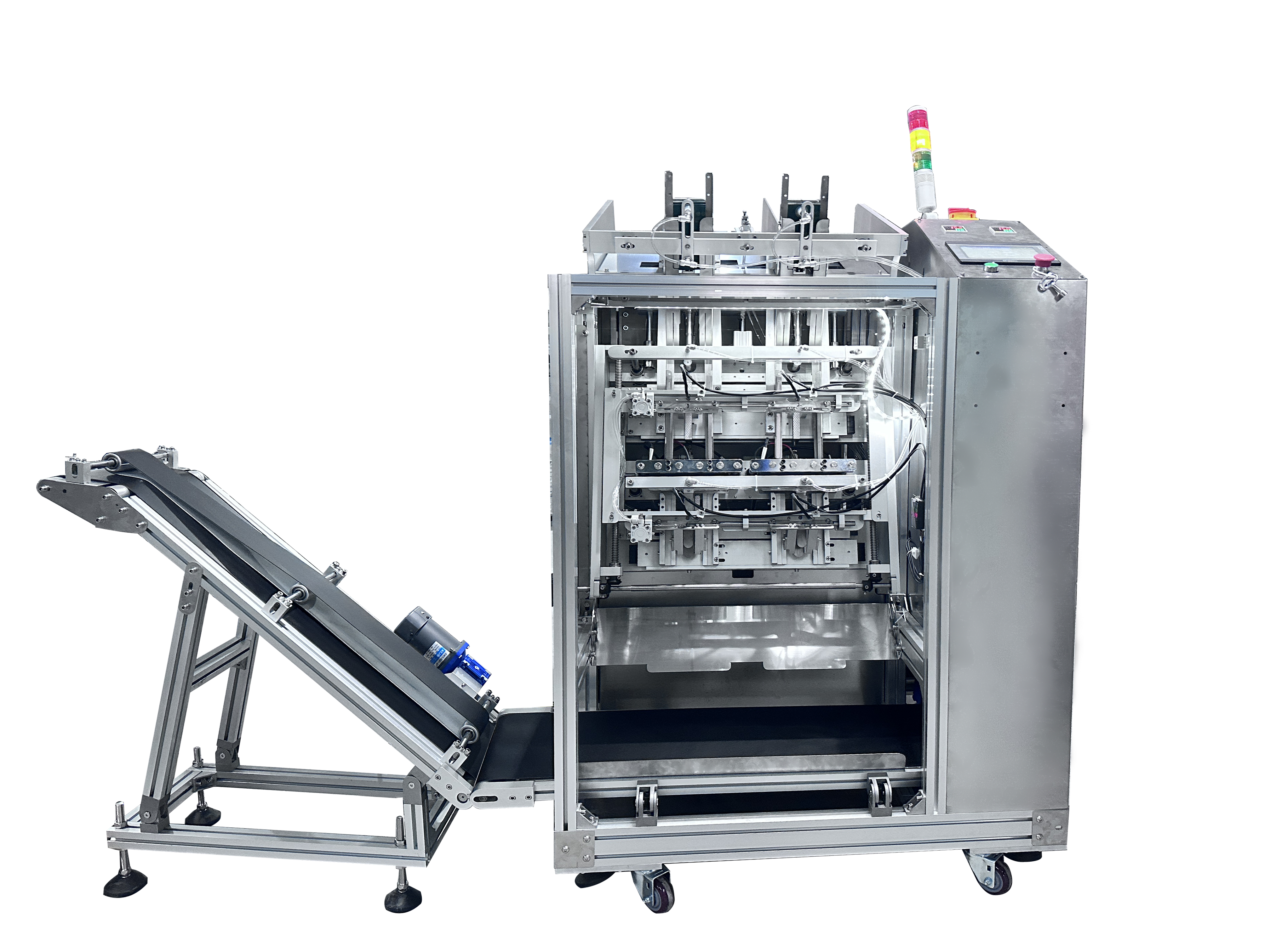

| WDMX2 double-head filling machine

(1) Efficiency: 2000-2500 tablets/hour, suitable for 95-160mm wide mask bags. (2) Technical highlights: magnetic pump filling (accuracy ± 0.2g), PLC + touch screen control, intelligent detection function of no bag no filling, saving labor cost. (3)Compatibility: Modularized design, support quick replacement of bag type without extra accessories. |

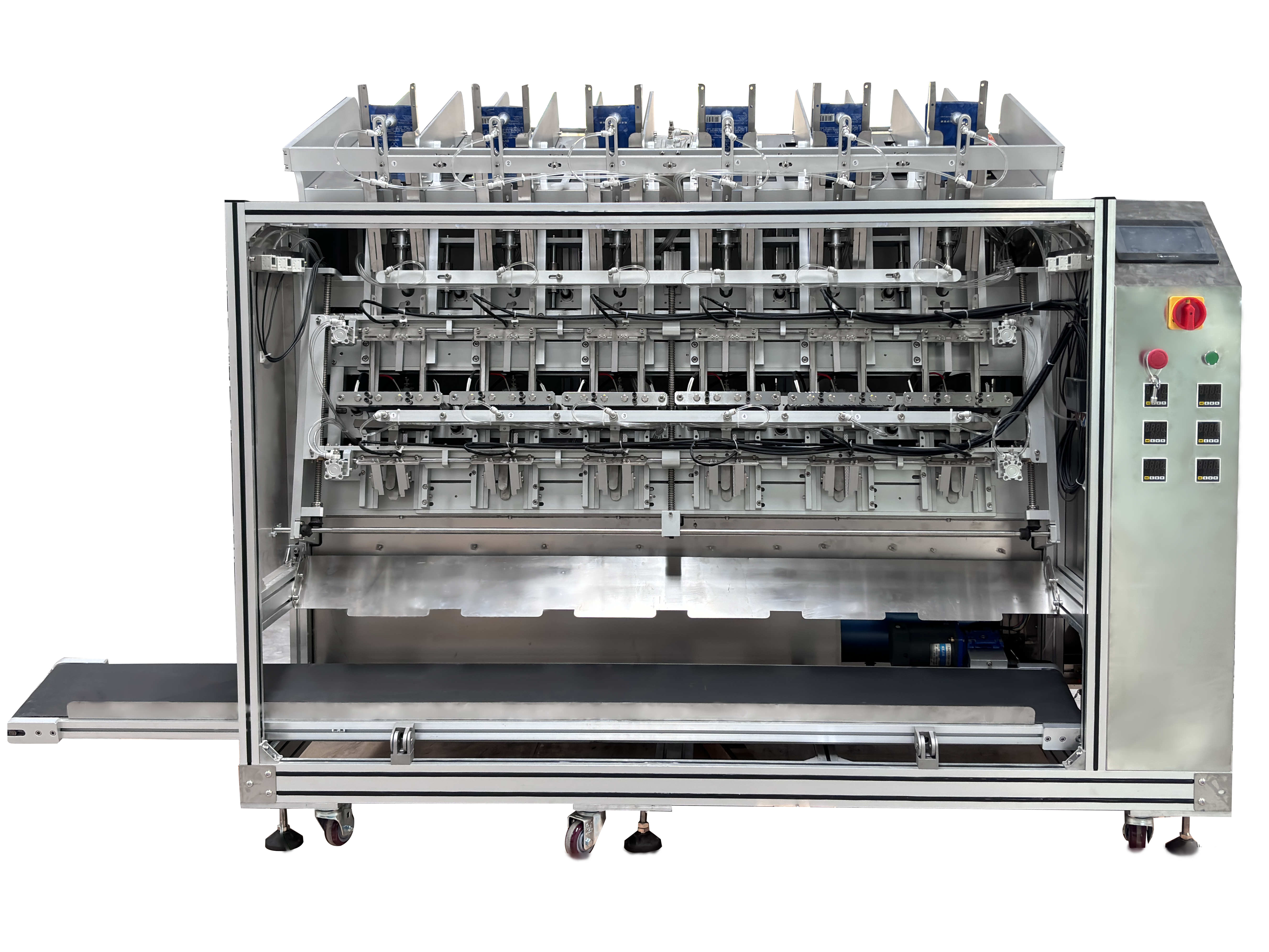

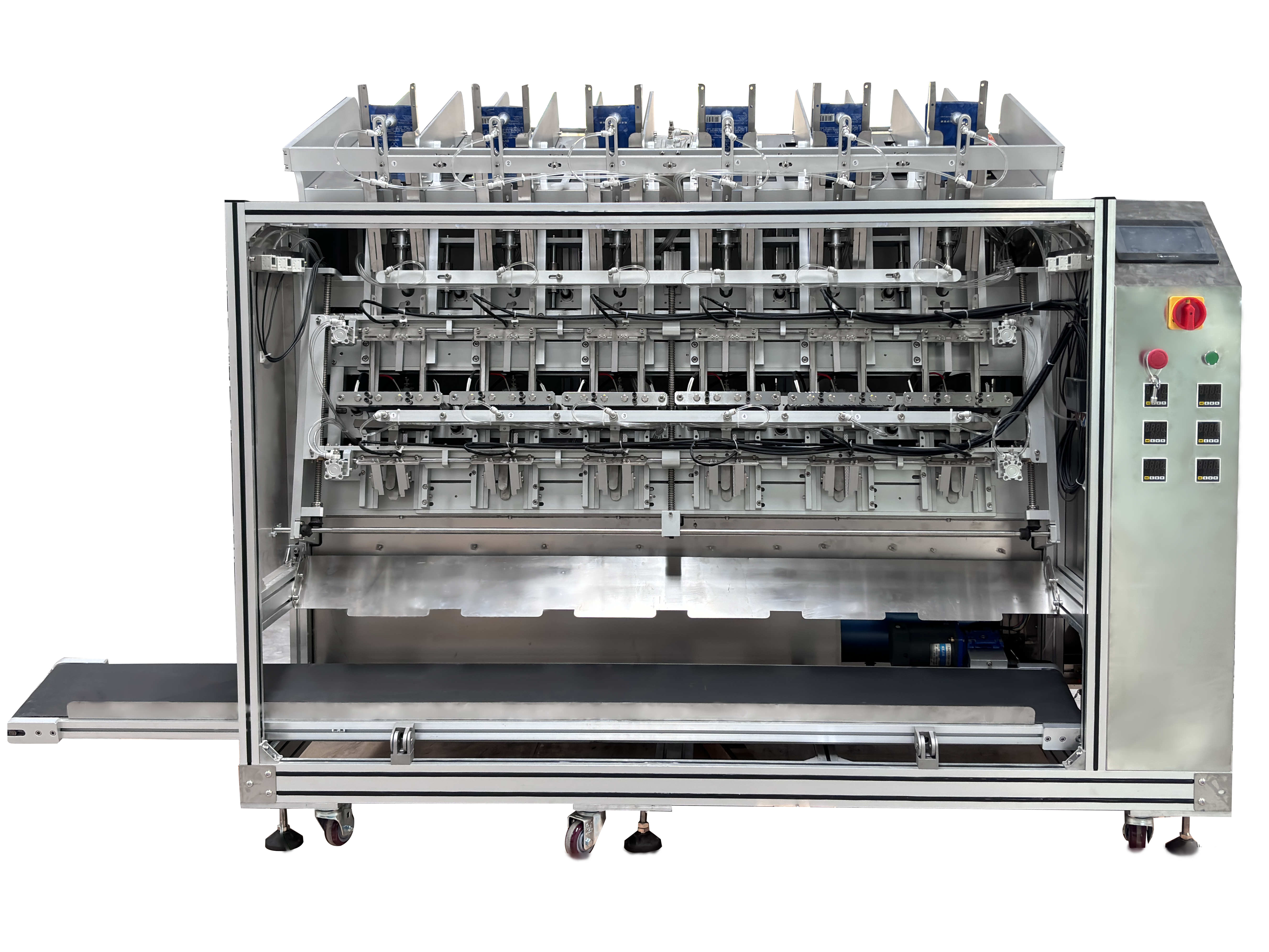

| WDMX6 Six Heads High Speed Filling Machine

(1) Efficiency: 7500-8500 bags/hour, suitable for mass production. (2) Automation process: integrated bag picking, filling, sealing, coding and finished product output, one key operation reduces failure rate. (3) Energy-saving design: 220V power supply, no need for industrial power electricity, reduce energy consumption and site restrictions. |

3.Fully automatic mask filling machine: high efficiency, precision, low consumption

Water treatment is the basic part of mask liquid proportioning, which directly affects the product safety and effect.

|

(1) Pure water preparation: adopts reverse osmosis technology to remove impurities and microorganisms in the water, providing pure water that meets GMP standards, extending the shelf life of the mask solution and enhancing the usage effect. (2) System Integration: Seamless connection with emulsifier and storage tanks to form a semi-finished product turnover center, providing a stable supply of raw materials for the subsequent filling process. |

4.One-stop production line integration benefits

(1) Cost Optimization: Full process automation from emulsification to filling reduces manual intervention and allows a single employee to operate 2-3 pieces of equipment.

(2) Quality Assurance: Passivation treated emulsifying pot + sterile pure water + high precision filling to ensure products meet international certification standards.

(3) Flexible Expansion: Support equipment combination upgrading (e.g. folding machine, labeling machine) to adapt to future capacity enhancement needs.

Whether you're a start-up or an established company, our emulsification, water treatment and filling equipment can be customized to help you achieve efficient, low-cost, high-quality production. Contact us today for a customized solution and quote!