Parameters

Model:WJMX2 |

1 | Motion Flow | Automatic bag lowering, automatic filling, automatic sealing, coding finished product output |

2 | Filling Heads | 2(Individually controllable) |

3 | Speed | 2000-2500PCS/H |

4 | Bag size | W:95-160mm L:105-220mm |

5 | Standard filling pump | Electronic Gear Pump |

6 | Filling precision | ±0.2g |

7 | Power supply | 380V/50Hz |

8 | power | 5KW |

9 | Air pressure | 0.6Mpa 300L/min |

10 | Equipment size | L926*W1300*H1400 |

Detail Image

|

Suction cup bag pickup

The machine automatically grabs the mask bag by suction cups and positions it to the filling station to ensure that the bag opening is aligned. |

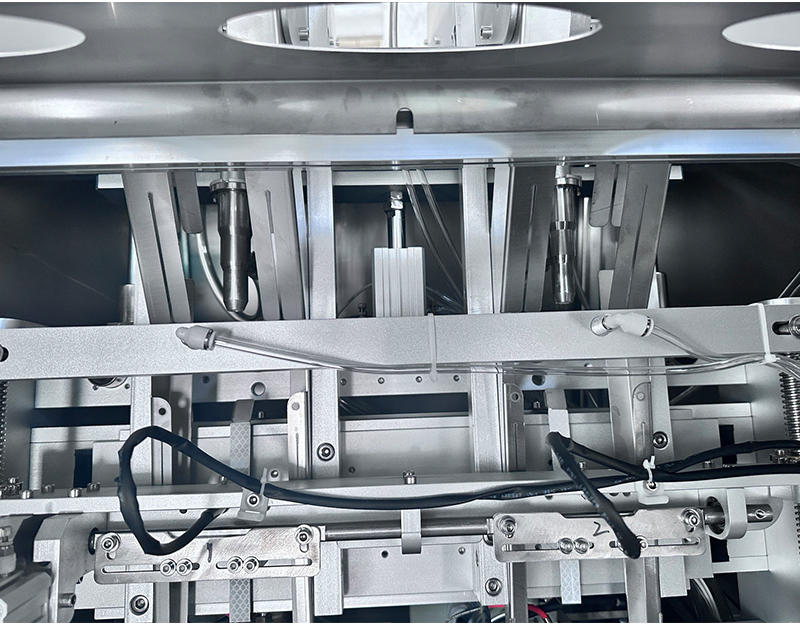

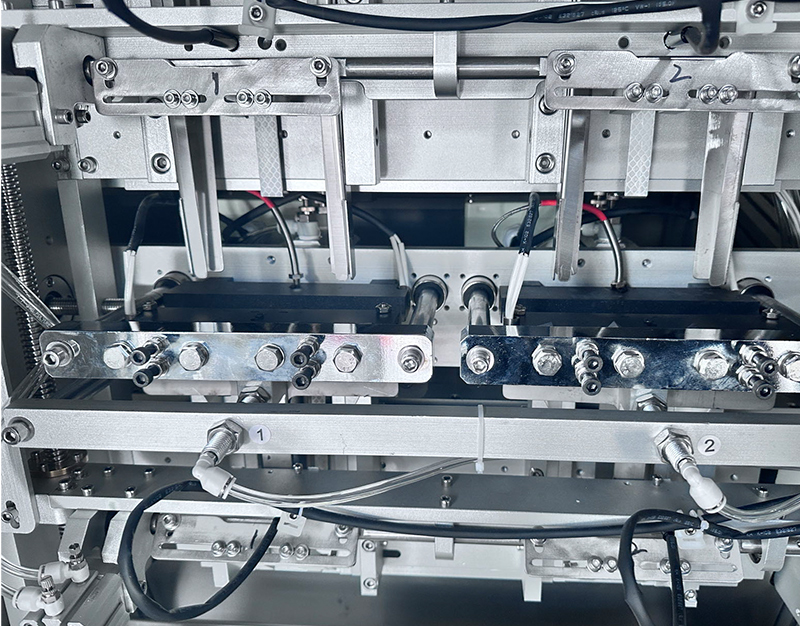

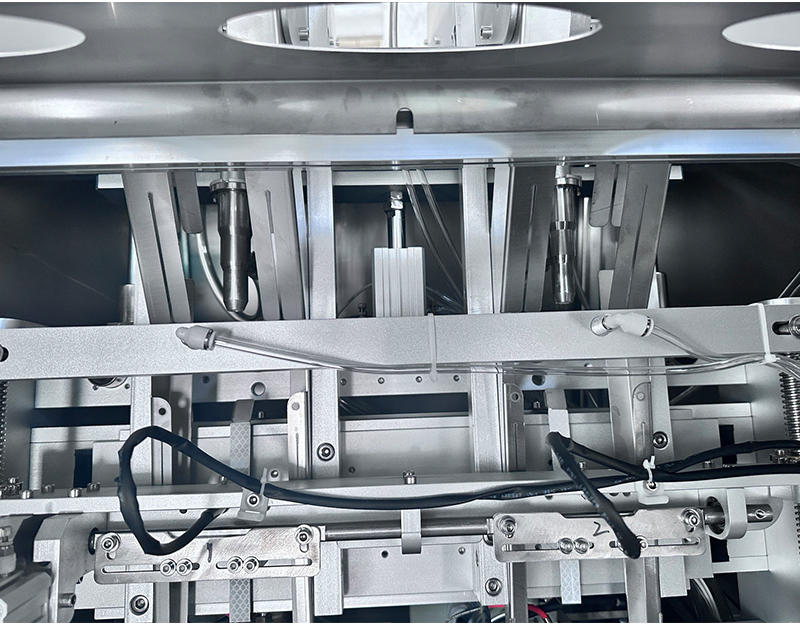

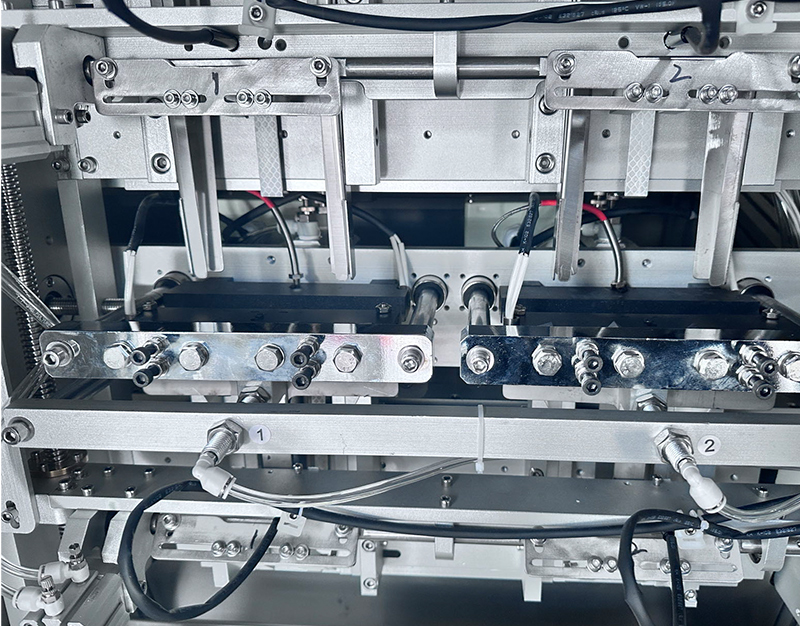

| Bag opening and filling Opening of the mask bag by means of a mechanical or pneumatic device to prepare it for subsequent filling

Dosing of the serum using a magnetic pump.

Excess air is discharged from the bag after filling to avoid liquid spillage or poor sealing during sealing.

|

|

Sealing and Coding

Heat sealing knife seals the mouth of the bag and prints the date of manufacture. |

|

Control System

PLC control: automatic control Temperature control: The temperature of the heat sealing knife is set by the temperature control meter. Emergency stop button: Abnormal emergency stop power off to ensure safety. |

Product Advantages:

1. Easy Maintenance: Its modular design allows for quick disassembly and assembly, facilitating routine cleaning and part replacement, minimizing downtime.

2. Intelligent Control: Equipped with a smart control panel, operators can easily adjust parameters like filling speed and volume, enhancing user experience.

3. Space-saving: Compact structure occupies less floor space in the production area, ideal for factories with limited room.

4. Gentle Filling: Adopts a special filling nozzle to avoid splashing and foaming of liquid, ensuring the integrity and quality of the facial mask essence.

Technical Features:

1. Anti-drip Filling Nozzles: Special nozzle design prevents liquid dripping after filling. This keeps the work area clean and ensures accurate dosing, reducing waste and maintaining mask quality.

2. Variable Frequency Speed Regulation: The motor uses variable frequency control, allowing operators to adjust the filling speed according to different liquid viscosities and production demands, optimizing efficiency.

3. Fault Self-diagnosis System: Built-in intelligent diagnosis can quickly identify equipment faults. It displays error codes on the control panel, enabling timely maintenance and minimizing production interruptions.

4. Ergonomic Design: The height and angle of the operation panel are adjustable to suit different operators. This reduces fatigue during long working hours and improves work comfort.

5. Sealing Pressure Adjustment: Can precisely adjust the sealing pressure. It ensures proper sealing for various mask materials, from thin silk to thick fiber, enhancing product integrity.

6. Remote Monitoring Function: Supports remote connection via Wi-Fi or Ethernet. Supervisors can monitor production status, adjust parameters, and receive real-time alerts from anywhere, enhancing management convenience.

FAQ:

1. How do I clean the filling machine?

The parts in contact with liquid can be disassembled easily. Use a mild detergent and warm water to clean, then rinse thoroughly and dry. The stainless steel 316 material ensures durability and easy cleaning. Make sure to unplug the machine before cleaning.

2. What if the filling amount is inaccurate?

First, check if the liquid viscosity has changed. If so, adjust the filling speed via the variable frequency control. Also, ensure the nozzles aren't clogged. Regular calibration using the provided tools can help maintain accuracy.

3. How do I handle a machine fault?

When a fault occurs, the self-diagnosis system will show an error code. Refer to the manual for the code meaning. Simple issues like loose connections can be fixed by operators. For complex problems, contact technical support.

4. Can I change the sealing type for different masks?

Yes, you can adjust the sealing pressure according to the mask material. For thin masks, lower pressure; for thick ones, increase it. The adjustable sealing feature accommodates various materials.

5. How to set up remote monitoring?

Connect the machine to your local network via Wi-Fi or Ethernet. Then, install the provided software on your monitoring device. Follow the setup wizard to pair the machine and start monitoring production status and adjusting parameters.