Product Advantages :

1. Precision Gas Filling: Ensures accurate, consistent gas quantities through advanced measurement and control systems, minimizing waste and optimizing resource utilization.

2. Gas Type Flexibility: Adapts seamlessly to a wide range of gases used in card furnace operations, such as natural gas, propane, or specialty blends, enhancing operational versatility.

3. Enhanced Safety Features: Incorporates multiple safety mechanisms, including leak detection, overfill protection, and automatic shutdown, to safeguard against potential hazards and ensure compliance with industry regulations.

4. Efficient Workflow Integration: Designed for smooth integration into existing card furnace facilities, streamlining gas tank filling processes and minimizing downtime for increased productivity.

5. User-Friendly Operation & Maintenance: Features intuitive controls, clear indicators, and accessible maintenance points, enabling operators to easily monitor, adjust, and service the machine without specialized training.

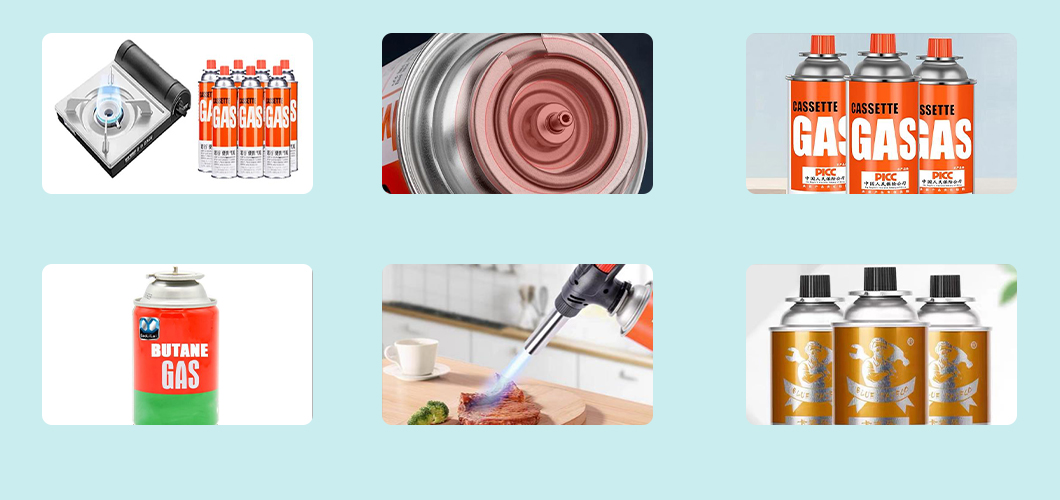

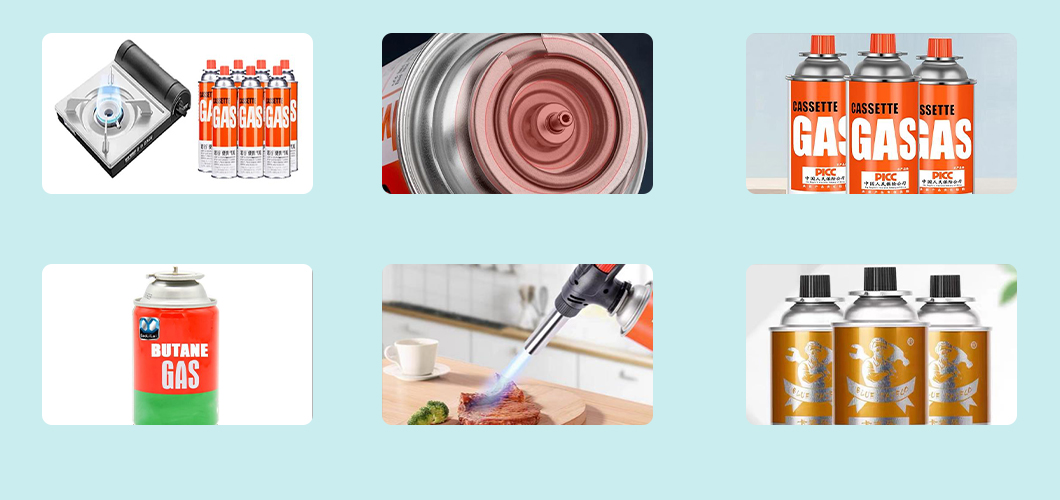

Applications:

1. Industrial Heating: Efficiently fills gas tanks for card furnaces used in manufacturing processes that require controlled, high-temperature heating, such as metal treatment, ceramics, or glass production.

2. Food Processing: Supports gas-fueled card furnaces in food industry applications, ensuring consistent gas supply for cooking, baking, or drying processes.

3. Research & Development: Facilitates experimentation and prototyping in R&D laboratories where card furnaces are utilized for material testing, thermal analysis, or chemical synthesis.

4. Maintenance & Repair: Enables quick, safe refilling of gas tanks for card furnaces undergoing routine maintenance, repairs, or upgrades, minimizing downtime and maintaining operational continuity.

5. Emergency Preparedness: Plays a vital role in emergency response plans by promptly refilling gas tanks for backup or emergency card furnaces, ensuring uninterrupted heat supply during power outages or critical situations.

Customization:

Model Number | QGJ70 |

Place of Origin | Guangdong |

Certification | CE&ISO9001 |

Supply Ability | 10sets per month |

Production speed | 60-70 cans / min |

Capacity | 30-750ml ( Can Be Customized) |

Speed | High |

Gas consumption | 6.5m 3/ Min |

Dimension | 22000*3000*2000 mm |

Technical Parameters:

This machine boasts a production rate spanning 100 to 120 bottles per minute, while its filling capacity varies from 30 to 750 milliliters. Remarkably, it maintains a repeat filling precision of ± 1%, underscoring its exceptional accuracy. It readily accommodates 1-inch valves and cans with diameters ranging from 35 to 73.85 millimeters, and widths up to 310 millimeters. Functioning optimally with a compressed air pressure of 0.7 to 0.85 megapascals and a gas usage rate of 5 cubic meters per minute, the machine is powered by an AC380V 50HZ supply. Customization options include compatibility with 220V 60HZ or 450V 60HZ power sources.

Packing and Shipping:

The Automated Filling Machine is packaged securely in a poly-wood box and shipped to the customer's location. The box is then secured with tape and labeled with an address sticker.

FAQ:

1. What is the production speed of this machine?

It fills gas tanks at a rate of 100 to 120 units per minute.

2. What is the filling volume range?

It can fill tanks with volumes from 30 to 750 milliliters.

3. What is the filling accuracy?

It achieves a repeat accuracy of ± 1%.

4. What valve sizes and can dimensions does it support?

It suits 1-inch valves and cans with diameters from 35 to 73.85 mm, width up to 310 mm.

5. What are the power and gas supply requirements?

Requires AC380V 50HZ power (customizable), 0.7 to 0.85 MPa air pressure, and 5 m³/min gas consumption.