Product Advantage

Save labor and increase production speed.

Increase product quality stability and reduce loss.

It adopts electric and compressor air drive.pneumatic disc selection and high safety.

Adopting six head rotation to raise production speed greatly.

Technical Parameters

Technical Parameter | Description |

Voltage | 380V/50HZ( can be customized ) |

Dimension(L*W*H) | 22000*4000*2000mm |

Production speed | 130-150 cans/min |

Propellant Type | The type of propellant used in the aerosol product (e.g., LPG, DME, N₂, CO₂, R134a, etc) |

Noise control | ≤80 dB |

Can Type | Tinplate can or aluminum can |

Driven Type | Pneumatic control |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

Filling accuracy | ≤±1% |

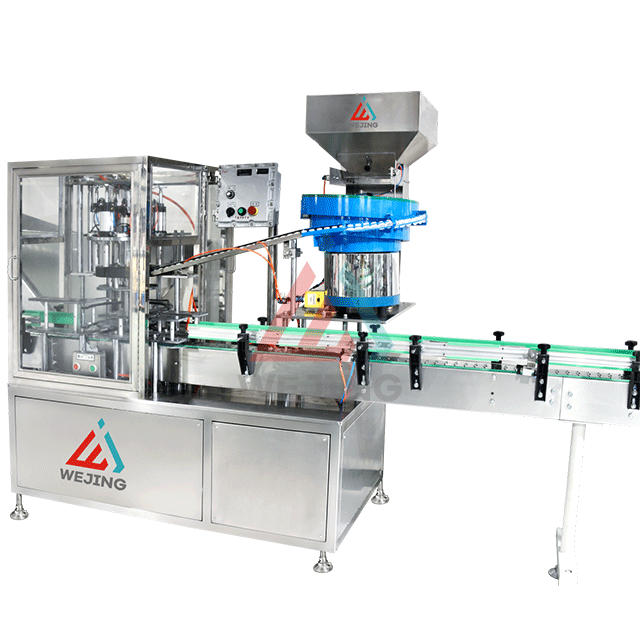

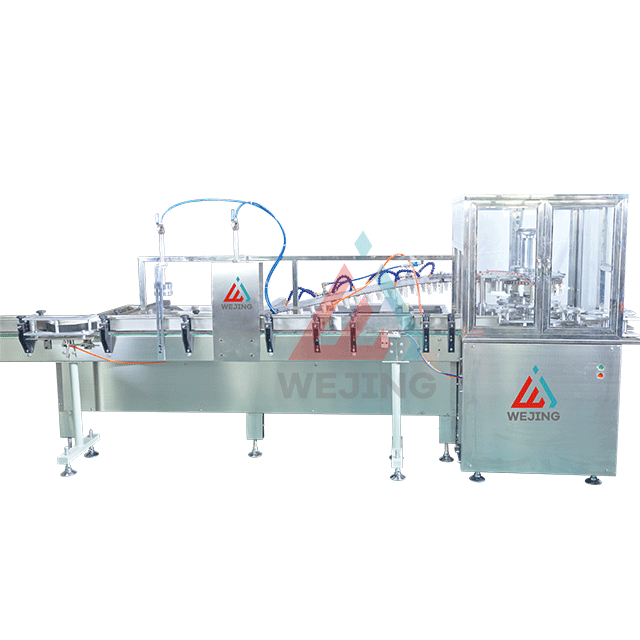

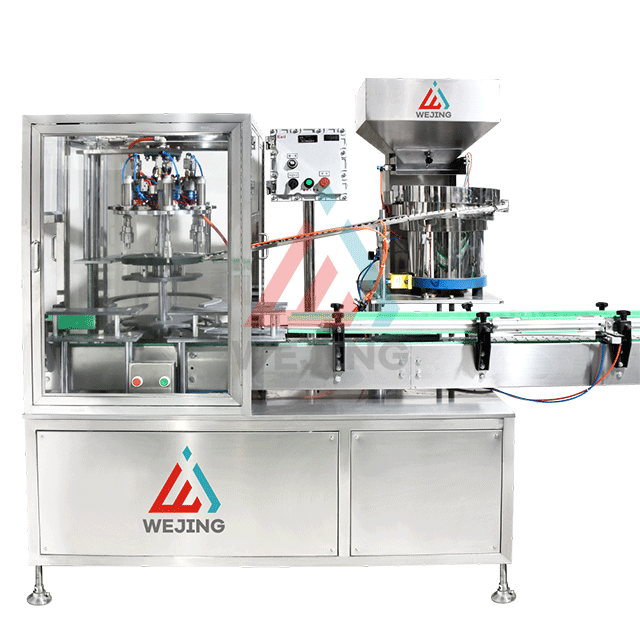

Detailed Images

Product Uses

1. Efficient aerosol filling: Enables high-speed and automated safety cover fixation during the aerosol filling process.

2. Increased productivity: Improves production efficiency by reducing manual labor and time consumption.

3. Consistent quality: Ensures uniform and reliable fixation of safety covers, enhancing product quality.

4. Safety enhancement: Provides a secure attachment of safety covers, minimizing the risk of leakage or exposure.

5. Compliance with standards: Helps manufacturers meet industry safety regulations and standards.

Product Operate Guide

1. Prepare the machine: Ensure the machine is properly assembled and connected to the aerosol filling line.

2. Load aerosol cans: Place the cans in the designated loading area of the machine.

3. Activate the machine: Switch on the machine and set the desired operating parameters.

4. Monitor the process: Observe the machine's operation and ensure smooth and accurate safety cover fixation.

5. Inspect the finished products: Check the fixed safety covers for proper attachment and quality.

FAQ

1. What is the function of the High speed auto safety cover fixed machine?

Answer: It is used to fix safety covers on aerosol cans automatically with high speed.

2. Can the machine be customized according to specific production needs?

Answer: Yes, the machine can be customized to meet different production requirements.

3. How does the machine ensure the accuracy of safety cover fixing?

Answer: It uses advanced technology and sensors to ensure accurate fixing of safety covers.

4. Is training provided for operating the machine?

Answer: Yes, training and instructions are provided to operators to ensure proper usage.

5. Can I get technical support and after-sales service for the machine?

Answer: Yes, our company provides comprehensive technical support and after-sales service.