Introduction

Ever wondered how the size of a packaging bag affects your bottom line? Whether you're shipping products or manufacturing goods, getting the right fit is crucial. In this article, we’ll dive into how to measure packaging bags accurately, the impact of proper sizing on efficiency, and why it’s essential for cost savings and product protection. Get ready to optimize your packaging process like never before!

1. Understanding Packaging Bag Sizes

1.1. Different Types of Packaging Bags

Packaging bags come in many different types, each designed to serve specific needs and accommodate different products. Some of the most commonly used types of packaging bags include poly bags, gusseted bags, vacuum bags, and stand-up pouches, each of which requires a slightly different approach to measuring. Poly Bags are versatile and lightweight, commonly used for packaging clothing, parts, and even food items. These bags are typically easy to measure because they are flat or lightly gusseted. On the other hand, Gusseted Bags have expandable sides that increase the bag's capacity, making them ideal for bulkier or irregularly shaped products. When measuring gusseted bags, it’s important to account for the expanded sides to get an accurate measurement of the bag's overall capacity. Vacuum Bags are another type where air is removed to shrink the bag around the product, ensuring it is tightly secured. For these bags, accurate measurements are critical to avoid overfilling, which can lead to ineffective sealing or product damage. Lastly, Stand-Up Pouches, often used in the food industry, are designed to stand upright for better presentation. These pouches usually have a bottom gusset that increases their capacity, and measuring them correctly requires attention to the length, width, and bottom gusset dimensions.

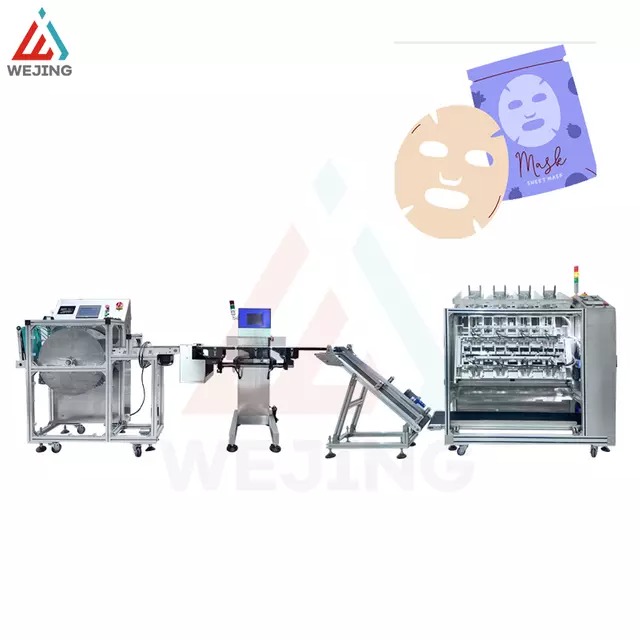

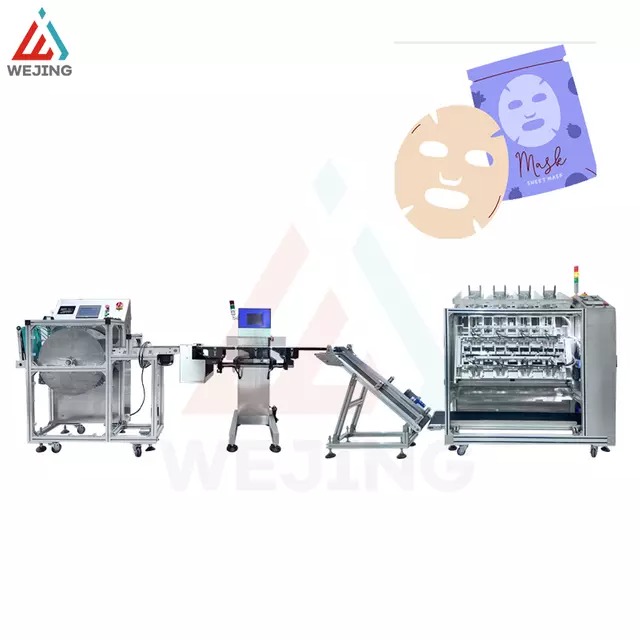

Each type of packaging bag affects how measurements are taken. For example, when filling facial masks using a Facial Mask Filling Machine, the bag must not only accommodate the product but also leave enough space for efficient filling and proper sealing. By ensuring that the packaging bags used for facial masks are correctly measured, manufacturers can significantly improve the efficiency and precision of their production lines.

1.2. Common Units of Measurement

When it comes to measuring packaging bags, there are various units of measurement, each suited to specific locations or industries. The most common units used in measuring packaging bags are inches, millimeters, and centimeters. Inches are the standard in countries like the United States, and they are often used for business transactions and everyday packaging. Millimeters (mm), however, are more commonly used internationally and in industries where precision is vital, such as manufacturing and scientific applications. Centimeters (cm) are used for smaller products and in regions that prefer metric measurements, offering a versatile middle ground between inches and millimeters.

The choice of units depends largely on the market you are serving and the nature of your business. For instance, if you're dealing with international shipping, it might be more practical to use millimeters or centimeters to ensure that packaging sizes meet global standards. For businesses that utilize automated machinery like the Facial Mask Filling Machine, it is also crucial to ensure that the machine’s specifications align with the measurement units of the packaging bags used. This helps in optimizing the filling process and ensures that bags are filled accurately and efficiently.

1.3. Why Proper Measurements Matter

Properly measuring packaging bags is essential for several reasons. Cost Efficiency is one of the most important aspects to consider. If the bags you are using are too large for your products, you may be wasting material, which increases your overall costs. On the other hand, if the bags are too small, you may end up damaging your products or needing to order more bags, both of which add unnecessary costs. The right size packaging bag ensures that the product fits snugly, minimizing waste and maximizing material usage. Additionally, correct sizing is critical for Product Protection. When packaging bags are too large, products may shift inside, potentially leading to damage during transport. A well-measured bag ensures that the product is secure, preventing breakage, contamination, or spoilage, which is particularly important when dealing with sensitive items like facial masks.

Proper bag sizes are also essential for Regulatory Compliance. Many industries, especially food and pharmaceutical sectors, have specific requirements for packaging sizes to meet safety and regulatory standards. If your packaging bags don’t meet these requirements, you may face fines, product recalls, or delays in shipping. Ensuring your packaging bags are the correct size helps maintain compliance with these regulations and keeps your business running smoothly.

Moreover, when using advanced machines like the Facial Mask Filling Machine, selecting the correct packaging bag size becomes even more important. This is because the filling machine is optimized for specific bag dimensions, and using bags that don’t fit correctly could lead to inefficiencies, such as product spillage or improper sealing. By ensuring accurate bag sizing, businesses can reduce downtime and improve the overall productivity of their production lines.

2. How to Measure the Size of Flat Packaging Bags

2.1. Measuring Length and Width

Measuring flat packaging bags is relatively straightforward, but accuracy is still crucial. The first step is to measure the Length of the bag, which is the distance from the top edge to the bottom edge when the bag is fully extended. To get the correct measurement, lay the bag flat on a smooth surface and use a ruler or measuring tape to measure the length. The next step is to measure the Width of the bag, which is taken across the bag from one side to the other at its widest point. This measurement is important because it ensures that the bag is wide enough to hold the product, but not so wide that it wastes material or leaves too much empty space.

It is important to note that when measuring flat bags, they should be fully extended and lying flat to get the most accurate dimensions. Avoid measuring when the bag is folded or wrinkled, as this can lead to inaccurate results. If you’re using a Facial Mask Filling Machine, ensure that the bags you choose are large enough to accommodate the volume of product being filled, but not so large that they create excess space inside.

2.2. The Role of Tolerances in Measurements

Manufacturing tolerances refer to the acceptable range of variation in the dimensions of a packaging bag. Tolerances are typically expressed as a range, such as ±0.5 inch, and they are essential to consider when selecting bags for your production line. It’s important to understand that tolerances in packaging bags can affect the final size, meaning that the bags you receive might be slightly different from the measurements you initially provided.

Tolerances should always be factored into the measurement process, as they can influence how well the bag fits the product, how it holds up during shipping, and how effectively the Facial Mask Filling Machine performs its job. For example, if the tolerances are too wide, the filling machine might not work efficiently, leading to wasted products or delays in the production process. Always check the tolerance specifications with your packaging supplier before placing an order to ensure that the bags will meet your exact needs.

2.3. Common Sizes of Flat Packaging Bags

Flat packaging bags are available in a variety of standard sizes to accommodate different products. Here are some typical flat packaging bag sizes:

Bag Size | Common Use |

10x12 inches | Small items like jewelry or accessories |

18x24 inches | Larger items like clothing or parts |

24x36 inches | Bulk items or large product packaging |

Selecting the right size depends on your product’s dimensions. If the product is too large for the bag, it may get damaged or improperly sealed. On the other hand, if the bag is too large, there will be excess space, which could result in product shifting during shipping. When filling facial masks using the Facial Mask Filling Machine, it's essential that the bag size matches the amount of product being filled to prevent wastage and ensure a proper seal.

3. Measuring Gusseted Packaging Bags

3.1. Understanding Gusseted Bags

Gusseted bags are designed with expandable sides, which provide more room for bulkier items. These bags are ideal for packaging products that are irregularly shaped or larger than typical flat items. The gusset allows the bag to expand and hold more, making it more versatile than flat bags. When measuring gusseted bags, it’s important to consider the gusset as part of the overall capacity.

For example, if you are using a Facial Mask Filling Machine and require a gusseted bag, the measurement must account for both the length, width, and gusset expansion. The correct size ensures that there is enough space for the facial mask, allowing it to be filled effectively and preventing spillage during the sealing process.

3.2. Measuring the Length, Width, and Gusset

To measure a gusseted bag, you need to account for three main dimensions: Length, Width, and the Gusset. The Length is measured from the top edge to the bottom edge of the bag, just like with flat bags. The Width is measured across the bag from one side to the other, at its widest point. Lastly, the Gusset is measured at its maximum expansion, which tells you the additional depth available in the bag.

This method ensures that you get the full capacity of the gusseted bag. For instance, when filling products such as facial masks, the gusset provides enough room to accommodate the product without forcing it into a tight space that could affect the bag's seal.

3.3. Examples of Common Gusseted Bag Sizes

Some typical gusseted bag sizes include:

Bag Size | Common Use |

12x16x4 inches | Bulk food items or textiles |

8x10x2 inches | Small parts or accessories |

These sizes offer flexibility for packaging larger or bulkier items. For facial mask production, selecting the correct gusseted bag size is critical to ensure the product fits securely, allowing for easy filling and sealing by machines like the Facial Mask Filling Machine.

4. Measuring Custom and Specialty Packaging Bags

4.1. Custom Packaging Bag Specifications

When ordering custom packaging bags, providing the right measurements is essential. Start by measuring your product accurately, and ensure the bag dimensions are tailored to fit perfectly. Custom bags often have wider tolerances, so be sure to clarify the acceptable range before placing an order.

For businesses like facial mask manufacturers using automated filling systems like the Facial Mask Filling Machine, custom bags ensure that each filled product is properly packaged and sealed without waste.

4.2. Specialty Bags: Vacuum, Stand-up Pouches, etc.

Specialty bags, such as vacuum bags or stand-up pouches, often require additional care when measuring because of the unique features they offer. For vacuum bags, accurate measurements ensure a snug fit once the air is removed, preventing issues with sealing. Stand-up pouches require measuring the length, width, and bottom gusset to ensure they stand upright correctly.

In the case of facial mask production, using vacuum-sealed bags with accurate measurements can significantly improve shelf life and product presentation. When using the Facial Mask Filling Machine, the right specialty bags enhance efficiency and ensure proper product containment.

4.3. Ensuring Fit with Your Product

When measuring custom or specialty bags, always check if the bag fits snugly around the product. Too much space inside the bag can lead to product shifting, while a bag that is too tight can damage the product. The right fit is crucial for maintaining product quality and efficiency.

Conclusion

Accurately measuring packaging bags is essential for ensuring cost-effectiveness, product safety, and regulatory compliance. By understanding the various types of bags and following the correct measuring procedures, businesses can optimize storage and shipping operations, reduce waste, and avoid unnecessary costs. In industries such as beauty and cosmetics, where precision is key to delivering quality products, ensuring the right bag size for filling machines like Wejing's Facial Mask Filling Machine is crucial. Properly measured bags ensure that products are protected, efficiently filled, and ready for shipment, making the production process smoother and more efficient. Taking the time to measure correctly will lead to long-term benefits for your bottom line.

FAQ

Q: What is the correct way to measure the size of a packaging bag?

A: To measure the size of a packaging bag, first measure its length from the top edge to the bottom edge, and then measure its width from side to side. For gusseted bags, also account for the gusset's expansion. This ensures accurate measurements for proper fitting.

Q: Why is it important to measure packaging bags accurately?

A: Accurate measurements of packaging bags help optimize storage and shipping efficiency, reduce material waste, ensure product protection, and comply with industry regulations, ultimately saving costs and enhancing production quality.

Q: How do I measure the size of a gusseted packaging bag?

A: When measuring a gusseted packaging bag, measure its length, width, and gusset (the pleated side). The gusset allows the bag to expand, providing extra capacity for bulkier items.

Q: What types of packaging bags require special measuring techniques?

A: Gusseted bags, vacuum bags, and stand-up pouches require special measuring. Gusseted bags need the gusset expansion measured, vacuum bags must be measured for proper fit once air is removed, and stand-up pouches require attention to the bottom gusset.