2024.6.6 update

Product Advantage:

1. This machine is a new type of equipment independently developed by the company. It consists of one sealing inflation head and two forced liquid filling heads combined on a table, saving space.

2. Adopting a linear screw bottle pushing system instead of the original transmission, the equipment can choose between jog and automatic modes during operation, which is flexible and efficient, with a high degree of automation and saves labor.

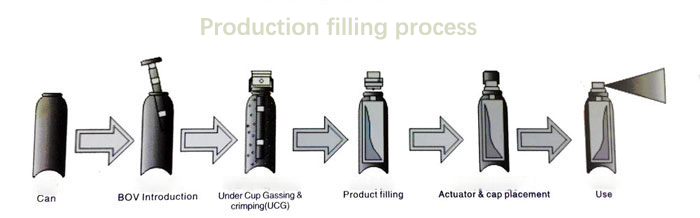

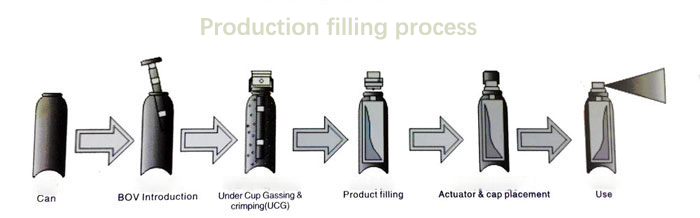

3. The machine fills the valve with propellant or compressed air while sealing the bag, and then injects liquid raw materials into the bag under high pressure. By completely isolating the raw materials from the tank, the problem of raw materials corroding the tank or preventing gas-liquid fusion is solved.

4. The main sealing components are imported to ensure sealing quality, stable equipment operation, and low failure rate.

Technical Parameters:

Filling capacity (cans/min) | 10-15 cans/min |

Liquid filling volume (ml) | 30-650ml |

Gas filling accuracy | ±0.03Mpa |

Liquid filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35-70 ( can be customized) |

Applicable cans height (mm) | 70-330 ( can be customized) |

Applicable valve (mm) | 25.4 (1 inch) |

Propellant | N2, compressed air |

Max gas consumption (m3/min) | 1m3/min |

Power (KW) | AC 220V/50HZ |

Air source | 0.6-0.7Mpa |

Dimensions | 1200×650×1670 mm |

Weight | 255 kg |

Product Uses:

This set of equipment has been widely used in medicine, health, fire protection, cosmetics and other industries, such as the filling and production of water-based cleaning agent, disinfectant, household fire extinguishing agent, tear gas, shaving foam, cosmetics spray, photocatalyst and other aerosol products with bags.

Guidelines for Selecting Filling Machines:

1. Make sure the product bottle and material you wanna filling

Weijing has been engaged in filling machinery for more than 10 years, with an excellent technical research and development team, specializing in the production of filling equipment for various materials such as filling aerosols, gases, liquids, pastes, powders, particles, etc.

2. Make sure the filling ranges you want

The selection of filling machines varies depending on the filling range.

3. Choose a brand filling enterprise

Choose models with mature technology and stable quality to make packaging faster and more stable, as well as low energy consumption, low labor, and low waste rate.

4. CAfter sales service

Wejing has a dedicated after-sales service team with guaranteed after-sales tracking to solve customer problems in the first time