Product Advantage:

1. Accurate Fill Control: Guarantees consistent fill levels to uphold premium product consistency and consumer satisfaction.

2. Continuous Pressure Management: Systematically verifies and sustains ideal internal pressures within each container, boosting both product efficacy and user safety.

3. Semi-Automated Operation: Optimizes efficiency through automated filling processes while preserving adaptability via manual handling of can loading and unloading tasks.

4. Sturdy Build: Fabricated from resilient materials for extended service life, inherent corrosion resistance, and full compliance with stringent hygiene and safety regulations.

5. Flexible Modularity: Enables straightforward maintenance, updates, and smooth assimilation into existing production layouts, catering to evolving manufacturing requirements.

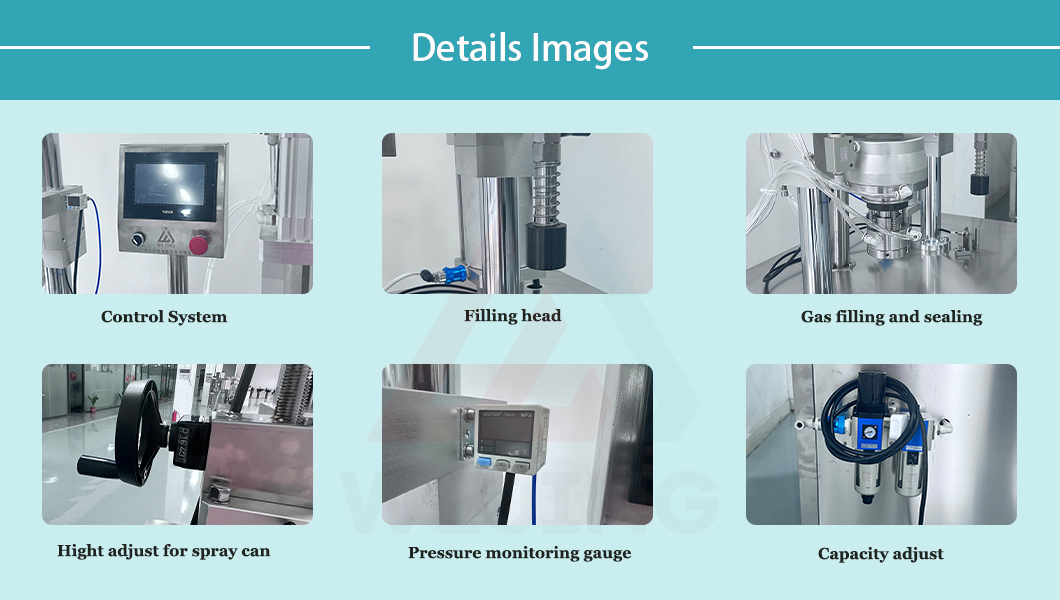

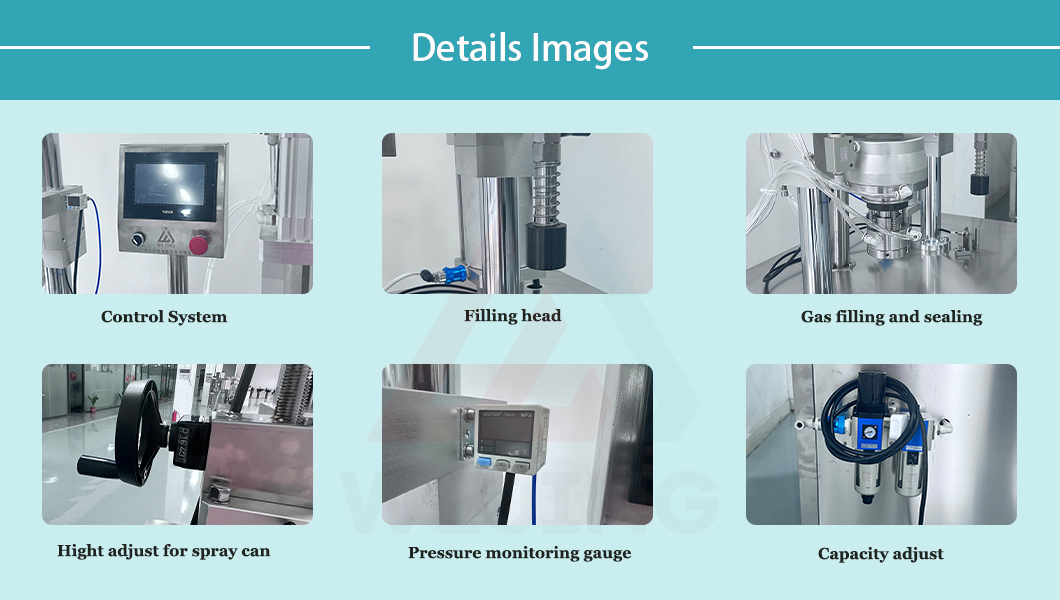

Detailed Images:

Applications:

1. Beauty & Grooming: Ideal for packaging hair sprays, deodorants, body mists, and assorted cosmetics that rely on consistent atomization and exact dosage accuracy.

2. Home Care Solutions: Catering to the production of air fresheners, cleaning agents, pest control products, and other household essentials demanding precise dispensation and dependable functionality.

3. Pharmaceutical Applications: Vital in the packaging of metered-dose inhalers, topical pharmaceuticals, and medical device sanitizers, where precision dosing and absolute sterility reign supreme.

4. Food & Beverage Sector: Suited for whipping cream dispensers, cooking sprays, and flavor enhancers, ensuring compliance with food safety standards and consistent flavor release.

5. Industrial Uses: Essential for filling lubricants, bonding agents, and specialized coatings utilized in automotive, engineering, and construction contexts, where accurate application and steadfast product characteristics are non-negotiable.

Technical Parameters:

Filling capacity (cans/min) | 45-60cans/min |

Liquid filling volume (ml) | 30-650ml/one stroke/head |

Gas filling accuracy | ±0.03Mpa |

Liquid filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35-70 ( can be customized) |

Applicable cans height (mm) | 80-300 ( can be customized) |

Applicable valve (mm) | 25.4 (1 inch) male BOV and female BOV |

Propellant | N2, compressed air |

Max gas consumption (m3/min) | 6m3/min |

Power (KW) | AC 220V/50HZ |

Air source | 0.6-0.7Mpa |

Our Service:

Pre-sales service:

Inquiry and consulting support.

Sample testing support.

24 hours on line answer your confusion.

Welcome to view our Factory.

Take video as client's request.

After-sales service:

We will adjust the machine to fit for yourproduct before delivery.

We provide useful instructions of machine.

Training how to install the machine, traininghow to use the machine.

FAQ:

1. What is a Fully Automatic Four-in-One Aerosol Filling Machine?

A single machine integrating sealing, centering, valve application, pressurization, and filling functions for aerosol cans.

2. How does the upper valve system work?

It automatically places and secures valves onto can tops before filling, ensuring proper alignment and airtightness.

3. Is operator intervention required during operation?

No, the machine operates autonomously from can loading to finished product output.

4. Can it handle various can sizes and shapes?

Yes, with quick-change tooling, it adapts to different aerosol can dimensions seamlessly.

5. How does it ensure filling accuracy?

Utilizing weight-based or volumetric filling technology, it consistently dispenses precise amounts of product.