2024.6.6 update

Product Advantage:

1. Precision Detection: The machine offers highly accurate leak detection, ensuring the integrity and quality of aerosol products.

2. Efficient operation: With its automated processes, the detecting machine saves time and increases productivity on the production line.

3. Versatile design: Suitable for different types and sizes of aerosol cans, the machine can be easily adapted to various production requirements.

4. Reliable performance: Built with durable components, the machine ensures consistent and reliable operation, minimizing downtime.

5. Safety features: The detecting machine incorporates safety mechanisms to protect operators and ensure a safe working environment.

Technical Parameters:

Water Bath Detecting Machine :

Temperature accuracy | ± 1 ℃ |

Water heating power | 45KW |

Drying power | 3kw |

Water tank capacity | 1.1m³ |

Max air consumption | 3m³ /min/0.6MPa |

Capacity | 130-150cans/min |

Main Drive Power | 2kw |

Soaking time | 3-5min |

Suitable can diameter | 35-73mm |

Suitable can height | 90-330mm |

Working Plate | SS304 |

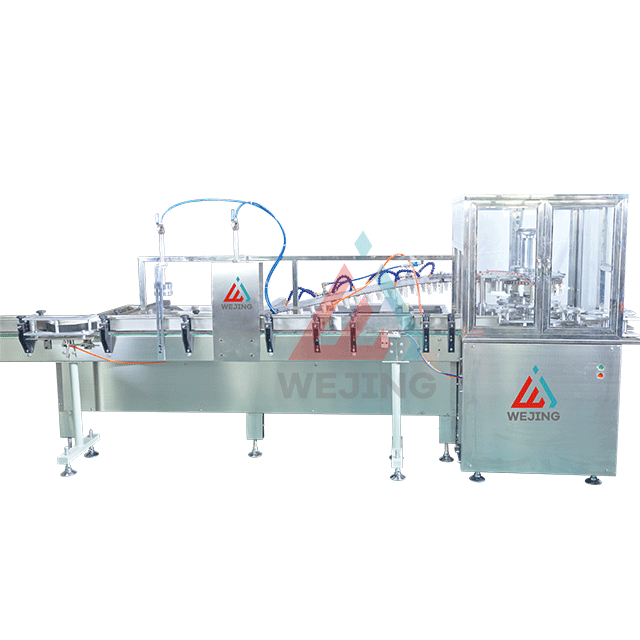

QGJ150 Aerosol Filling Machine Line:

Technical Parameter | Description |

Voltage | 380V/50HZ( can be customized ) |

Dimension(L*W*H) | 22000*4000*2000mm |

Production speed | 130-150 cans/min |

Propellant Type | The type of propellant used in the aerosol product (e.g., LPG, DME, N₂, CO₂, R134a, etc) |

Noise control | ≤80 dB |

Can Type | Tinplate can or aluminum can |

Driven Type | Pneumatic control |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

Filling accuracy | ≤±1% |

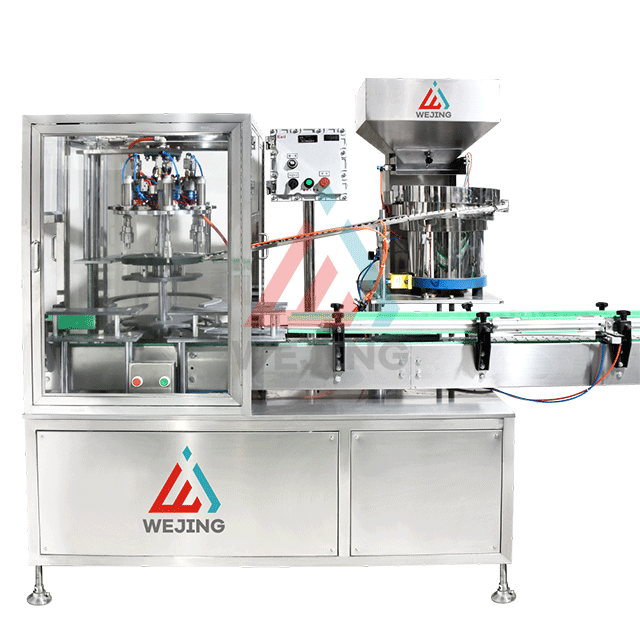

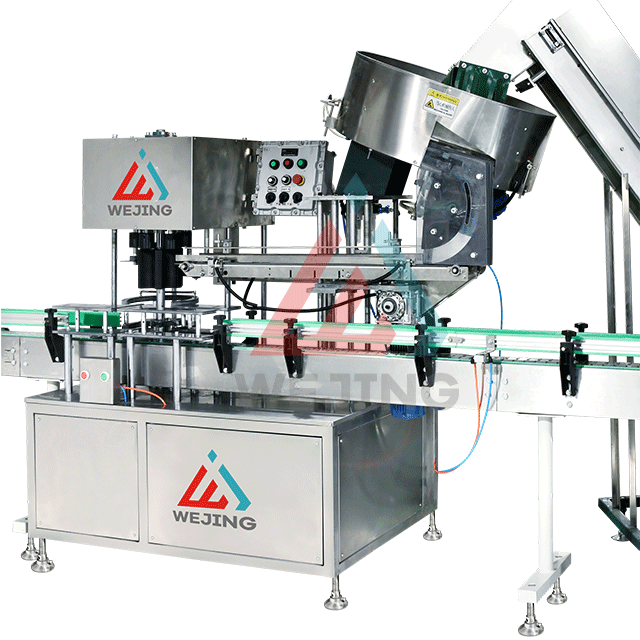

Detailed Images:

Product Uses:

1. Quality control: Detects leaks and defects in aerosol cans to ensure product quality.

2. Safety assurance: Identifies potential safety hazards, ensuring the safety of aerosol products.

3. Production efficiency: Automates the detection process, increasing productivity.

4. Compliance: Helps manufacturers comply with industry standards and regulations.

5. Brand protection: Maintains brand reputation by ensuring consistent product quality.

Product Operate Guide:

1. Prepare the machine: Ensure the machine is properly installed and connected to power and water sources.

2. Load aerosol cans: Place the aerosol cans to be tested into the designated positions on the machine.

3. Set parameters: Adjust the testing parameters according to the specific requirements of the production line.

4. Start the detection: Initiate the detection process by activating the machine's controls.

5. Monitor and analyze results: Observe the machine's output and analyze the test results to ensure product quality.

FAQ:

1. What is the function of the Water Bath Detecting Machine?

Answer: It is used to detect leaks and defects in aerosol cans during the filling process.

2. How does the machine work?

Answer: The cans are placed in water and pressurized to identify any leaks or faults.

3. Can it handle different can sizes?

Answer: Yes, it is designed to accommodate various sizes of aerosol cans.

4. Is the machine easy to operate?

Answer: Yes, it features a user-friendly interface and simple controls.

5. What are the benefits of using this machine?

Answer: It improves product quality, ensures safety, and increases production efficiency.