Configuration:

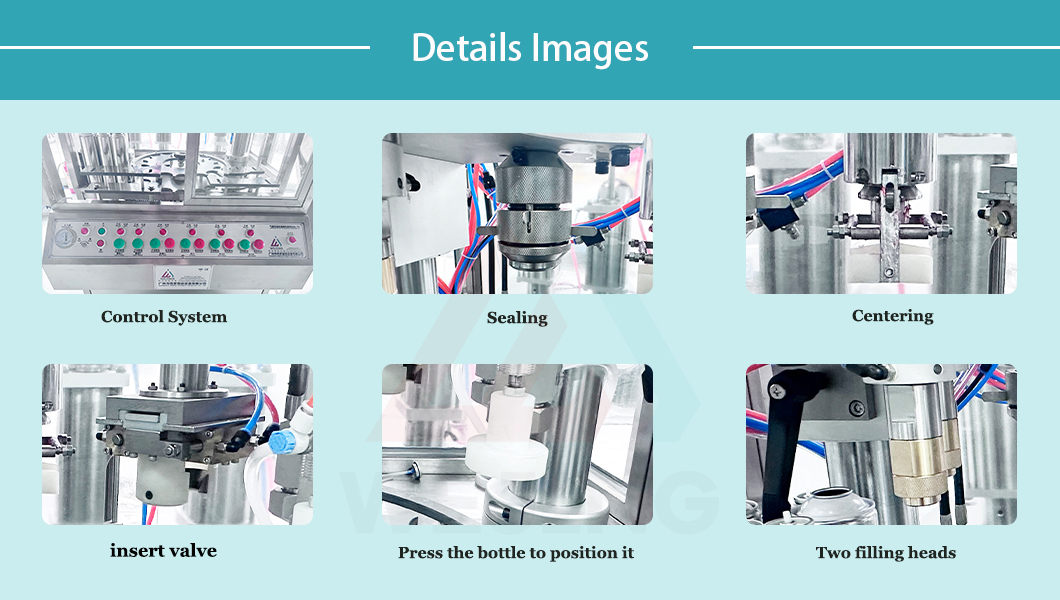

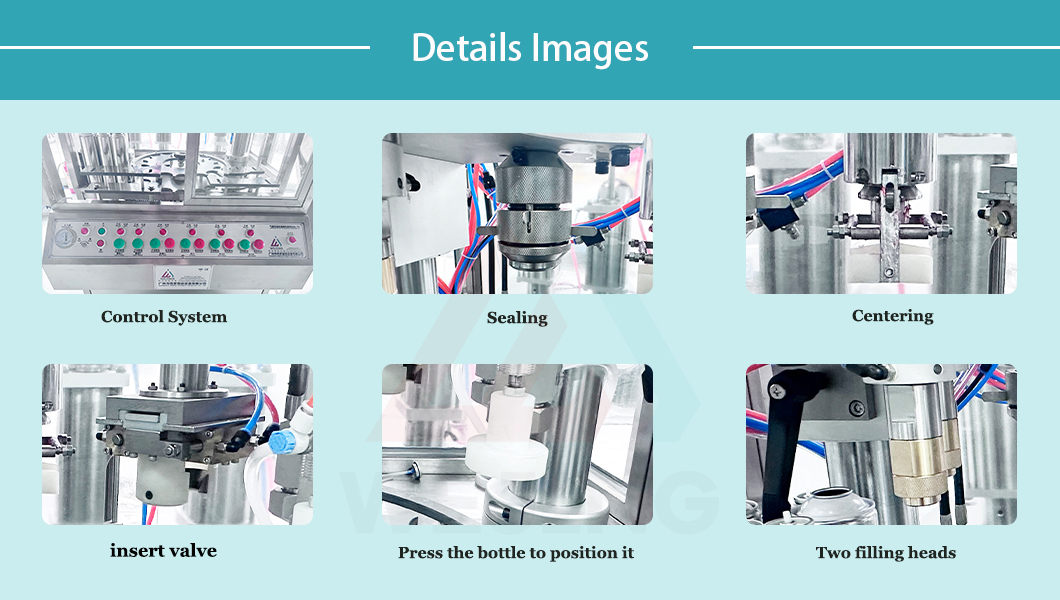

1. Integrated Efficiency: Combines valve insertion, filling, crimping, and gas injection in one streamlined process, optimizing production flow and reducing cycle times.

2. Precision Valve Placement: Advanced valve upper technology ensures accurate valve fitting, enhancing seal quality and minimizing leakage, thereby improving product quality.

3. Adaptability & Flexibility: Suited for diverse aerosol products, accommodating varying fill volumes and propellants. Quickly adjusts to different can sizes, meeting bespoke manufacturing demands.

4. Ease of Use & Maintenance: Intuitive control panel simplifies operation, reducing operator training needs. Robust design allows for effortless cleaning and maintenance, ensuring continuous high-performance operation and longevity.

Technical Parameters:

Production speed | 60-70 bottles/min |

Filling volume | 10-300ml |

Repeated filling accuracy | ±1% |

Can size | 1inch aerosol can, diameter:φ40-φ70 height: 85-300mm |

Pressure of air compressed | 0.7-0.85Mpa |

Air consumption | 5m³/min |

Power supply | AC380V/50Hz/1.1KW |

Detailed Images:

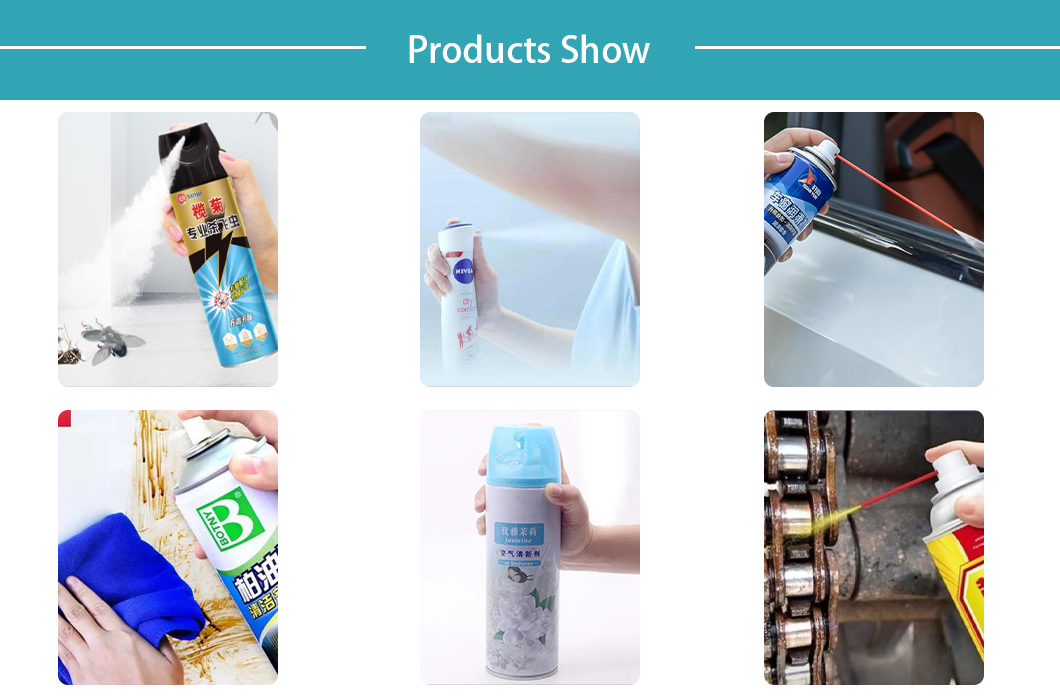

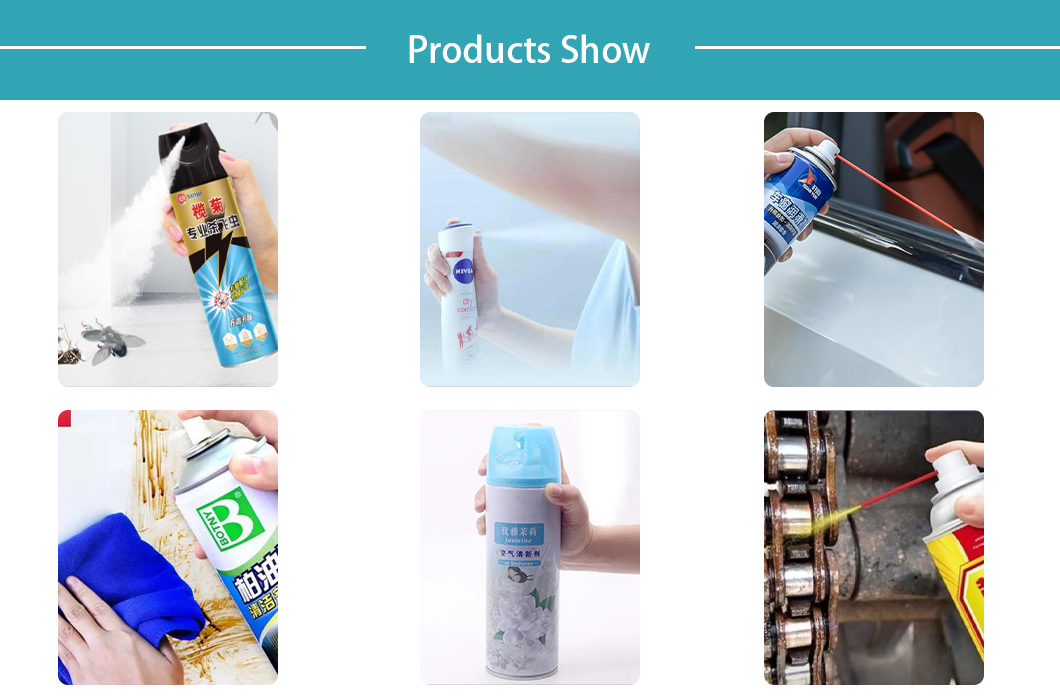

Products:

1. Personal Care Industry: High-speed aerosol filling technology is pivotal in the creation of personal care goods ranging from deodorants, hair sprays, body mists, shaving gels, to numerous cosmetic aerosols, offering hygienic and efficient packaging solutions.

2. Household Cleaning Solutions Manufacturing: These systems are indispensable for the mass production of home cleaning agents like air fresheners, insecticides, antibacterial sprays, furniture polish, and heavy-duty oven cleaners, assuring both large-scale productivity and uniform product superiority.

3. Pharmaceutical and Healthcare Sphere: In pharmaceuticals, the use of rapid aerosol filling systems is essential for the production of metered-dose inhalers, topical medications, and antiseptic sprays, demanding meticulous dosage accuracy and adherence to rigorous industry standards for safety and efficacy.

FAQ:

1. What does a 4 in 1 Aerosol Filling Machine with Valve Upper Function include?

It integrates valve insertion, product filling, crimping, and gas injection, streamlining the entire aerosol packaging process.

2. How does the Valve Upper Function enhance the machine's performance?

It ensures precise valve placement, improving seal integrity and reducing leaks, thus enhancing product quality.

3. Can the machine accommodate various product types and sizes?

Yes, it's designed for versatility, handling different aerosol products, volumes, and can dimensions with ease.

4. Is the machine suitable for both small batches and large-scale production?

Absolutely, its adaptable settings make it ideal for both small-scale customization and high-volume manufacturing runs.

5. How does the machine ensure compliance with industry standards?

It's built with features that adhere to strict safety and quality regulations, ensuring products meet industry benchmarks.