Configuration:

1. Streamlined Functionality: Unites valve embedding, substance filling, crimping, and pressurization into a single, seamless operation, streamlining manufacturing processes and trimming production cycles.

2. Optimized Valve Alignment: Employs sophisticated valve deployment mechanisms to guarantee precise valve alignment, fortifying seal tightness and dramatically reducing seepage, which in turn elevates product integrity.

3. Versatility and Adjustability: Tailored for a broad array of aerosol applications, adeptly managing differing fill levels and accommodating a variety of propellants. Swiftly conforms to diverse can dimensions, fulfilling customized production requisites.

4. User-Friendliness & Low Maintenance: Features an easy-to-navigate control interface that eases operation, lessening training demands on personnel. Its sturdy construction promotes simplified cleaning and upkeep, preserving peak operational efficiency and extending equipment life span.

Technical Parameters:

Production speed | 60-70 bottles/min |

Filling volume | 10-300ml |

Repeated filling accuracy | ±1% |

Can size | 1inch aerosol can, diameter:φ40-φ70 height: 85-300mm |

Pressure of air compressed | 0.7-0.85Mpa |

Air consumption | 5m³/min |

Power supply | AC380V/50Hz/11KW |

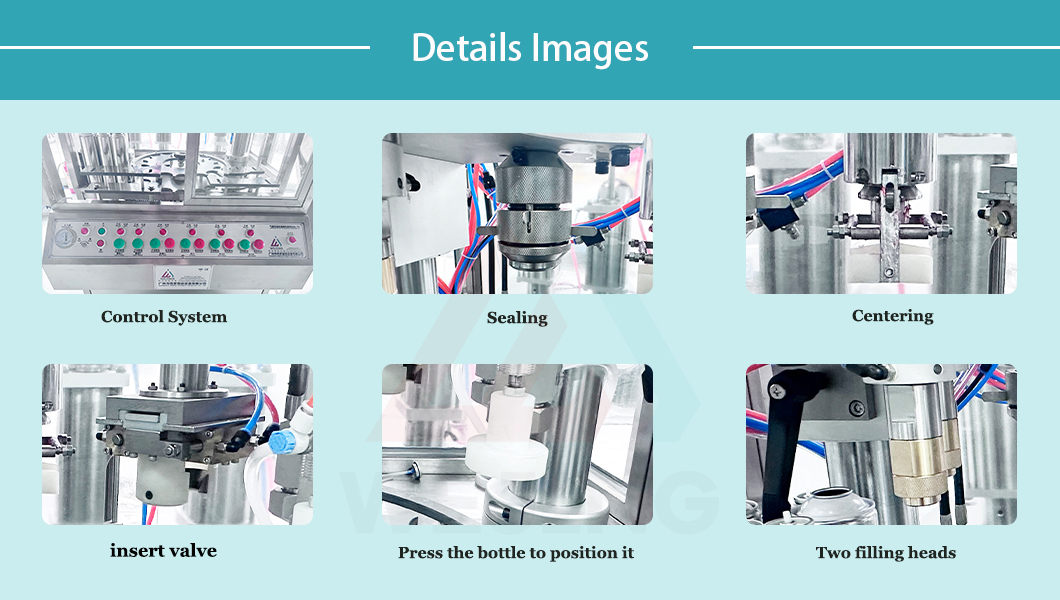

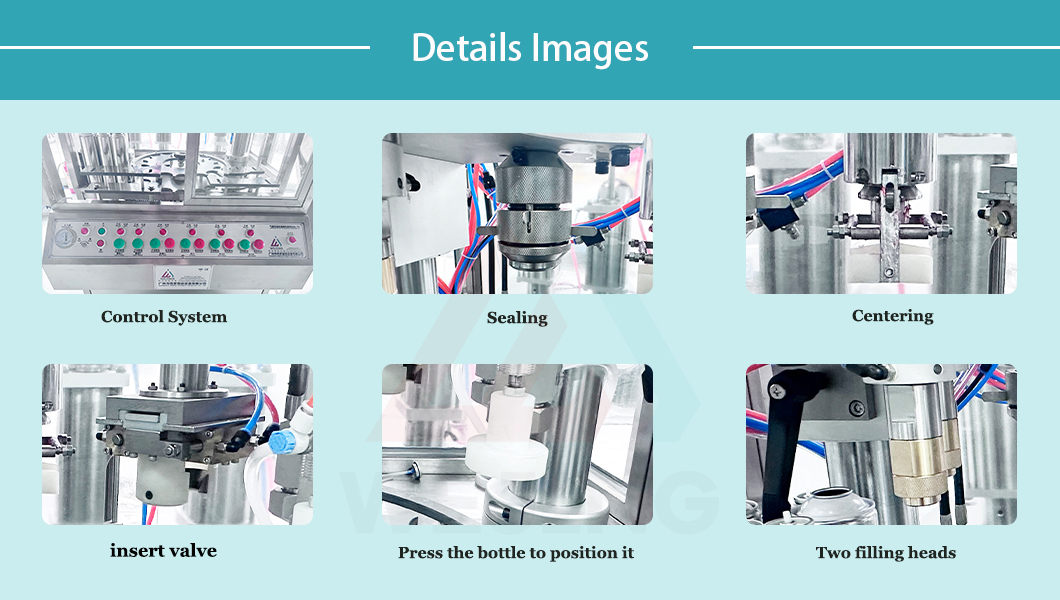

Detailed Images:

Products:

1. Personal Care Product Innovation: High-speed aerosol filling techniques form the backbone of manufacturing personal hygiene and beauty products, encompassing deodorants, hair styling sprays, body fragrances, shaving creams, and an array of cosmetics, providing hygienic packaging solutions that are both efficient and secure.

2. Home Cleaning Product Mass Production: Integral to the fabrication of household cleaning essentials such as air purifiers, insect repellent sprays, antibacterial solutions, furniture shine enhancers, and powerful oven cleaning agents, these systems guarantee not only mass output but also consistent product excellence across the board.

3. Healthcare and Pharmaceutical Applications: Rapid aerosol filling technology plays a crucial role within the pharmaceutical sector for the creation of precisely dosed inhalers, external treatments, and disinfection spray, necessitating absolute precision in measurement and unyielding conformity to stringent healthcare standards for assured safety and effectiveness.

FAQ:

1. What constitutes a 4 in 1 Aerosol Filling Machine equipped with Valve Upper Functionality?

This machine consolidates the tasks of valve installation, substance filling, crimping, and gas charging into one process, effectively harmonizing the complete aerosol packaging workflow.

2. In what way does the Valve Upper Function contribute to the machine's enhanced performance?

By guaranteeing accurate valve positioning, this function reinforces seal tightness and curbs leaks, thereby uplifting the overall product excellence.

3. Is the machine capable of handling diverse product categories and dimensions?

Indeed, it's engineered for adaptability, effortlessly managing a spectrum of aerosol goods, varying volumes, and can sizes to suit diverse manufacturing needs.

4. Is the machine apt for production runs that are both small and large scale?

Certainly, its flexible configurations make it well-suited for both modest custom batches and substantial mass production cycles.

5. How does the machine maintain adherence to industry standards?

It's designed incorporating functionalities that comply with stringent safety and quality norms, assuring that the end-products conform to established industry criteria.