2024.6.12 update

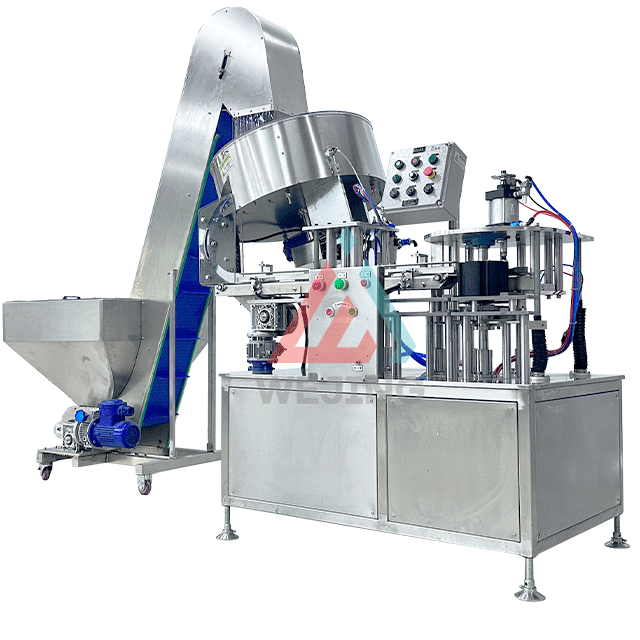

Product Advantage:

1. Highly efficient: This machine can automatically insert and fix plastic caps, significantly increasing production efficiency.

2. Precise positioning: By employing advanced technology, it guarantees that plastic caps can be accurately inserted into containers.

3. Simple to operate: The user-friendly design makes it simple to operate and understand, eliminating the need for professional training.

4. Highly adaptable: It can be adjusted to suit different products and production requirements, easily adapting to various production environments.

5. Quality assured: Only high-quality materials and components are used, and product quality is strictly controlled to ensure the stability and durability of the equipment.

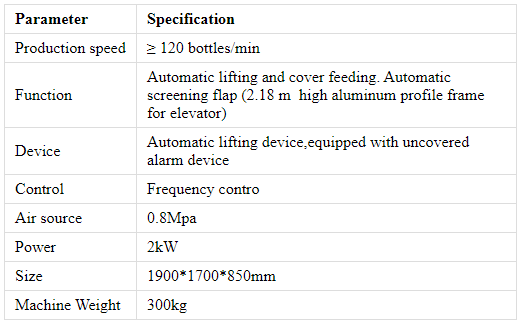

Technical Parameters:

Product Uses:

1. Automatic plastic cap insertion and fixation in aerosol filling lines: This machine is ideal for aerosol production.

2. Packaging of cosmetic bottles: In the cosmetics industry, this machine can be used for packaging various cosmetic products like hairspray and deodorant.

3. Bottled liquid or gas drug packaging: The machine is suitable for use in the pharmaceutical industry for packaging liquid or gas drugs.

4. Packaging of household chemicals: The Auto Plastic Cap Inserted And Fixed Machine finds application in packaging cleaning agents, air fresheners, and other household chemicals.

5. Food product packaging: It can be employed in the food industry for packaging sauces, dressings, and beverages among other food items.

Product Operate Guide:

1. Machine preparation: Ensure the machine is assembled correctly and all components are in good condition.

2. Cap loading: Put the plastic caps into the cap feeder of the machine.

3. Settings adjustment: Set the appropriate parameters, including speed and insertion force, based on the caps and bottles being used.

4. Machine start: Press the start button to initiate the cap insertion and fixing process.

5. Process monitoring: Keep a close watch on the machine to ensure it is functioning smoothly and address any issues that arise immediately.

FAQ:

1. What is the purpose of the Auto Plastic Cap Inserted And Fixed Machine?

Ans: The machine is designed to automatically insert and secure plastic caps onto aerosol cans during the filling process.

2. What are the key components of the machine?

Ans: The machine typically comprises a cap feeder, cap insertion mechanism, cap fixation device, control system, and safety features.

3. How does the machine ensure precise cap insertion?

Ans: The machine utilizes sensors and servo motors to accurately position and insert the caps, ensuring consistent and accurate placement onto the cans.

4. Can the machine handle various types of aerosol cans?

Ans: Yes, the machine can be adjusted or customized to accommodate different sizes, shapes, and materials of aerosol cans to meet specific production requirements.

5. What are the benefits of using this machine in a production line?

Ans: By automating the cap insertion and fixation process, the machine can enhance production efficiency, reduce labor costs, improve product quality, and enhance workplace safety.