Product Advantage:

1. Fill Consistency Assurance: Ensures uniform fill depths to maintain superior product uniformity and delight consumers.

2. Uninterrupted Pressure Regulation: Methodically confirms and maintains optimal pressure conditions within each container, enhancing product effectiveness and user protection.

3. Hybrid Automation: Maximizes efficiency through automated filling procedures while maintaining adaptability through manual control over can loading and unloading activities.

4. Robust Construction: Crafted from durable materials for prolonged durability, innate corrosion resistance, and unfailing conformity to rigorous hygiene and safety guidelines.

5. Adaptable Modularity: Facilitates effortless maintenance, upgrades, and seamless integration into established production setups, accommodating shifting manufacturing demands.

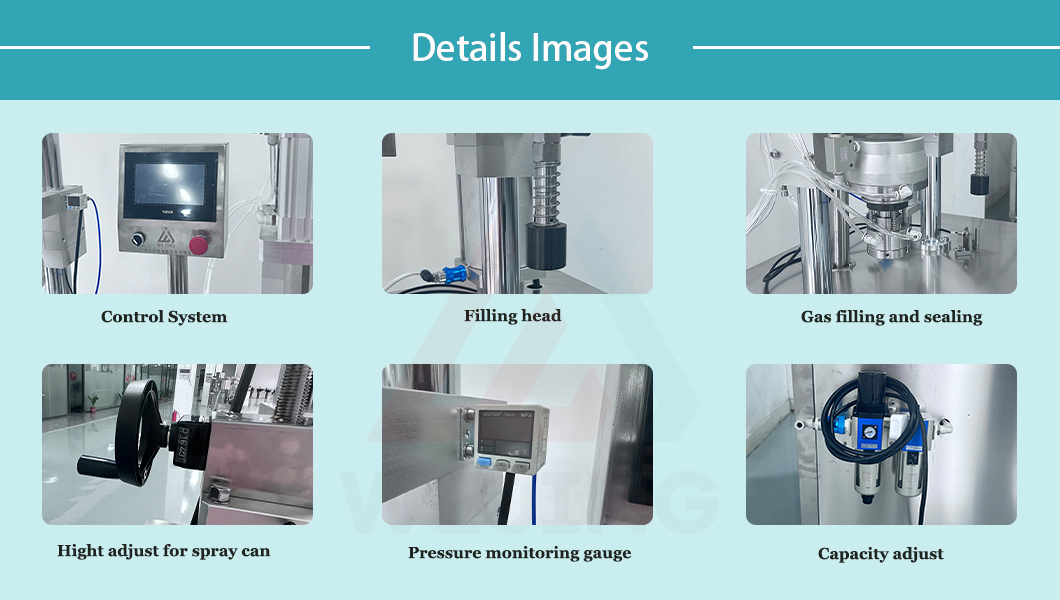

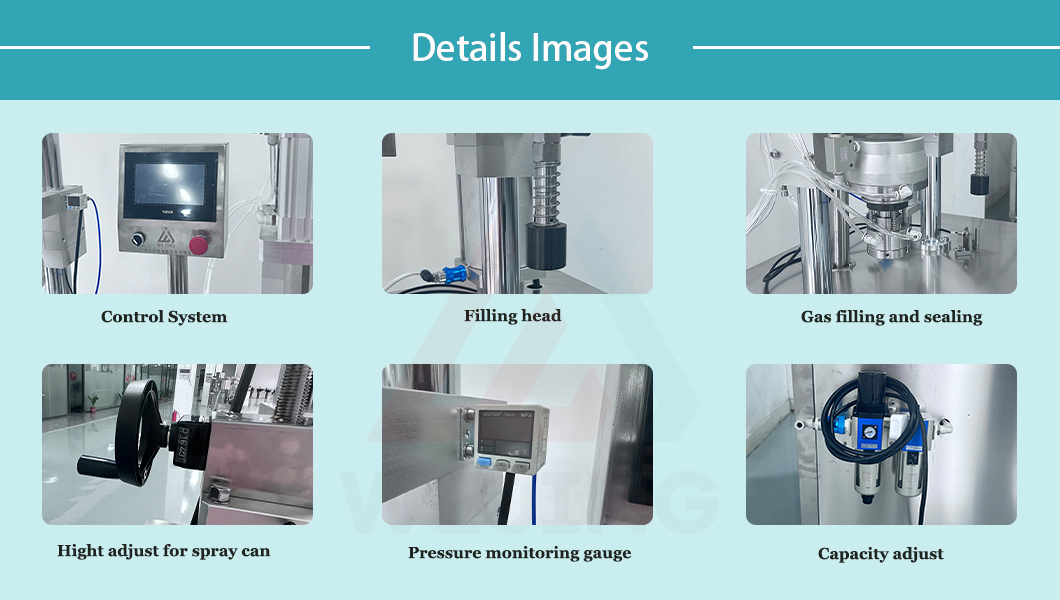

Detailed Images:

Applications:

1. Personal Care Packaging: Perfect for encasing hair sprays, deodorants, body mists, and diverse cosmetic formulations requiring uniform dispersion and pinpoint dose precision.

2. Domestic Care Production: Tailored to the creation of air fresheners, cleansing solutions, pest repellents, and various home staples needing accurate dosing and unfailing performance.

3. Pharmaceutical Packaging Needs: Crucial in the containment of metered-dose inhalers, topical drugs, and medical device disinfectants, where exact dosing and absolute sterility hold utmost importance.

4. Culinary Applications: Well-suited for whipped cream dispensers, cooking sprays, and flavor intensifiers, guaranteeing adherence to food safety norms and uniform flavor delivery.

5. Industrial Filling Tasks: Indispensable for filling lubricants, adhesives, and specialized coatings used in automotive, engineering, and construction settings, where exact application and rock-solid product traits are imperative.

Technical Parameters:

Filling capacity (cans/min) | 10-15 cans/min |

Liquid filling volume (ml) | 30-650ml |

Gas filling accuracy | ±0.03Mpa |

Liquid filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35-70 ( can be customized) |

Applicable cans height (mm) | 70-330 ( can be customized) |

Applicable valve (mm) | 25.4 (1 inch) |

Propellant | N2, compressed air |

Max gas consumption (m3/min) | 1m3/min |

Power (KW) | AC 220V/50HZ |

Air source | 0.6-0.7Mpa |

Dimensions | 1200×650×1670 mm |

Weight | 255 kg |

Our Service:

Pre-sales service:

Query and consultation assistance.

Assistance with sample testing.

Round-the-clock resolution of your uncertainties.

Invitation to tour our manufacturing facility.

Video documentation upon client request.

After-sales service:

Machine customization to accommodate your product prior to dispatch.

Comprehensive machine usage guidelines provided.

Installation and operational training sessions offered.

FAQ:

1. What constitutes a Fully Automatic Four-in-One Aerosol Filling Machine?

A solitary apparatus combining sealing, centering, valve attachment, pressurization, and filling capabilities specifically for aerosol containers.

2. How does the machine apply valves to cans?

It mechanizes the positioning and securing of valves onto can lids pre-filling, thereby ensuring correct alignment and hermetic sealing.

3. Does the machine necessitate any manual involvement during its cycle?

Not at all; it executes all tasks, from can feeding to final product formation, in an autonomous manner.

4. Is the machine capable of accommodating diverse can formats?

Indeed, through the use of rapid-change tooling, it seamlessly adjusts to accommodate various aerosol can sizes and geometries.

5. How does it guarantee precision in the filling process?

Employing either weight-based or volumetric filling techniques, it consistently dispenses exact quantities of the product.