Introduction

The cosmetics industry is booming, with new brands emerging daily. However, starting a cosmetics business comes with its own set of challenges.

One critical aspect of success is ensuring efficient production. A cosmetic filling machine plays a vital role in achieving this goal.

In this article, we’ll discuss the key equipment needed for your cosmetics business, focusing on the importance of the cosmetic filling machine for streamlining production and maintaining product quality.

Understanding the Importance of Cosmetic Filling Machines

How Cosmetic Filling Machines Work and Why They're Crucial

A cosmetic filling machine automates the process of filling various cosmetic products, such as creams, lotions, oils, and gels, into containers like bottles, jars, or tubes. These machines are designed to fill containers with precise amounts of product, ensuring consistency across every unit.

In the production process, the cosmetic filling machine plays a crucial role in maintaining product integrity. By filling products accurately, it prevents overfilling or underfilling, which could lead to waste, customer dissatisfaction, and financial losses. It also ensures the product remains free from contamination, which is essential in an industry where hygiene is critical.

The efficiency of a cosmetic filling machine is particularly important when scaling production. As businesses grow and demand increases, relying on manual labor alone becomes inefficient and costly. These machines offer a much faster and more reliable solution, allowing businesses to meet market demands while maintaining high standards of quality.

Benefits of Using a Cosmetic Filling Machine in Your Business

Using a cosmetic filling machine brings multiple advantages that make it a wise investment for businesses of all sizes:

Increase production efficiency: These machines operate at high speeds, filling large quantities of products in a short time. This allows businesses to scale production without sacrificing quality.

Ensure product consistency: The automatic nature of these machines ensures that each container is filled with the exact amount of product. This consistency is essential for building customer trust and brand reputation.

Reduce waste: Machines are programmed to fill containers precisely, preventing overfilling or spillage, and ultimately minimizing waste. This makes your production process more sustainable and cost-effective.

By integrating a cosmetic filling machine, your production process becomes more reliable, streamlined, and scalable—key factors in keeping up with consumer demands in the competitive cosmetics market.

Factors to Consider When Choosing a Cosmetic Filling Machine

When selecting a cosmetic filling machine, several factors must be considered to ensure that the equipment aligns with your product needs and business scale:

| Factor | Consideration | Recommended Machine Type |

| Product Type | Thick creams, gels, lotions, oils | Piston Filling Machine, Liquid Filling Machine |

| Production Scale | Small batch vs large-scale production | Semi-Automatic vs Fully Automatic Machines |

| Budget | Cost-effective vs high-end solutions | Manual Machines vs Automated Machines |

These factors will help you make a well-informed decision on the cosmetic filling machine that best fits your production needs and financial goals.

Other Essential Equipment for Starting a Cosmetics Business

Capping Machines: Sealing Your Products Securely

After your products are filled, they must be sealed to ensure they remain fresh and secure during shipping and storage. A capping machine ensures that each container is tightly sealed, preventing leaks, contamination, or spoilage. These machines can handle various cap types, including screw caps, flip-top caps, and snap-on caps.

The choice of capping machine depends on the type of container you use. For instance, screw capping machines are ideal for jars, while snap-on cap machines are better suited for tubes. The speed and reliability of the capping machine ensure that products are sealed quickly and securely, maintaining both the product's quality and its presentation.

Conveying Systems: Enhancing Production Flow and Efficiency

A conveying system is crucial in optimizing the movement of products throughout the production line. These systems automatically transport containers from one station to the next, whether it’s from the filling station to the capping station or from the labeling station to packaging. By automating this process, you reduce the need for manual handling, which increases efficiency and reduces the risk of contamination.

Conveying systems can be customized to meet your specific production layout, helping to maintain a smooth workflow. This automation is essential for large-scale operations, as it helps to streamline production and reduce downtime, ultimately improving your business’s overall efficiency.

Labeling and Coding Systems: Ensuring Product Traceability

Accurate labeling and coding are vital to maintaining product traceability and meeting regulatory standards. A labeling and coding system automatically applies labels with important information such as product details, batch numbers, expiration dates, and ingredient lists. This ensures that products are properly identified and compliant with industry regulations.

Additionally, these systems help with inventory management and ensure that each product batch is traceable, which is crucial in the event of a recall or quality control issue. Integrating a labeling and coding system into your production line helps maintain brand consistency and builds consumer trust by providing clear product information.

Cleaning and Sanitization Equipment: Maintaining Hygiene Standards

In the cosmetics industry, maintaining hygiene standards is crucial to avoid contamination and ensure product safety. Cleaning and sanitization equipment helps maintain cleanliness in the production line by removing residues from filling nozzles, tubes, and other equipment parts.

A clean-in-place (CIP) system allows you to clean the filling and sealing machines without disassembling them, saving time and ensuring a thorough clean. Regular cleaning ensures that your equipment remains in good working condition, reduces downtime, and helps you comply with industry hygiene regulations.

Types of Cosmetic Filling Machines for Different Products

| Filling Machine Type | Best Suited For | Key Features |

| Piston Filling Machine | High-viscosity products (creams, gels) | Precision for thick formulations |

| Liquid Filling Machine | Liquids and semi-liquids (lotions, oils) | High-speed, volumetric filling |

| Tube Filling Machine | High-viscosity liquids (toothpaste, creams) | Tube filling with sealing capabilities |

Piston Filling Machines for High-Viscosity Products

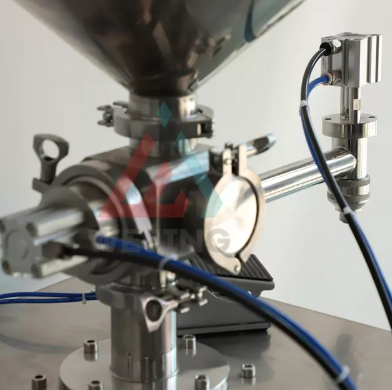

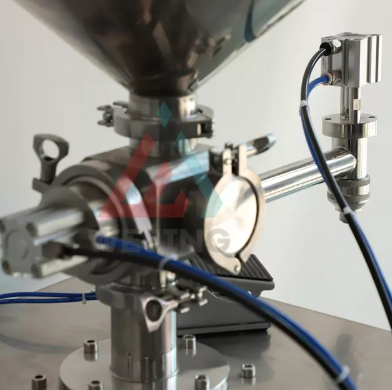

Piston filling machines are perfect for handling high-viscosity products such as creams, gels, and pastes. These machines use a piston-driven mechanism to accurately dispense the product into containers. They are ideal for thicker formulations that may not flow easily, ensuring consistent fills and minimal waste.

For businesses that specialize in thicker cosmetic products, investing in a piston filling machine is essential to maintain product quality and meet production goals efficiently.

Liquid Filling Machines for Liquids and Semi-Liquids

For products like lotions, oils, and serums, liquid filling machines are ideal. These machines typically use volumetric or peristaltic mechanisms to dispense precise amounts of liquid into containers. They are well-suited for high-speed production lines, ensuring rapid output without compromising on product quality.

Liquid filling machines are designed for liquid-based products but can also handle semi-liquid formulations, making them a versatile option for many cosmetics manufacturers.

Tube Filling Machines: Precision for High-Viscosity Liquids

Tube filling machines are essential for filling products in tubes, such as toothpaste, sunscreens, and certain cosmetic creams. These machines offer high precision, ensuring that each tube is filled with the exact amount of product. Some tube filling machines also include sealing capabilities, ensuring that the product is sealed properly to maintain freshness and prevent leakage.

Choosing Between Automatic and Manual Filling Machines

The decision between automatic and manual filling machines largely depends on your production scale. Automatic machines are faster, more efficient, and ideal for large-scale operations where high-volume production is essential. However, they require a higher initial investment.

On the other hand, manual filling machines are more affordable and are suitable for smaller batches or startups that are just beginning to scale their operations. They may require more labor but can still provide reliable results for low-volume production.

Key Considerations When Choosing the Right Filling Machine

Matching the Right Machine to Your Product and Packaging

Choosing the right filling machine starts with understanding the specific needs of your product. Different products, such as thick creams, runny lotions, and oils, have unique characteristics that determine the most suitable filling technology. For example, piston filling machines are ideal for high-viscosity products like creams and gels because they provide precise control over the amount dispensed. In contrast, liquid filling machines are better for more fluid products, such as oils or lotions, as they can fill containers quickly and efficiently without compromising on accuracy.

Beyond the product type, consider your packaging format. Whether you’re using tubes, jars, or bottles, each type of container requires a machine that can handle its unique shape and size. Tube filling machines, for instance, are specifically designed for filling and sealing tubes, while jar filling machines are often used for thicker products. Understanding your packaging requirements is crucial to ensuring you select the right machine for a smooth production process.

Automation vs. Manual Filling: Which is Better for Your Business?

Deciding between automated and manual filling machines depends on several factors, including your business’s scale, production goals, and budget. Automated filling machines offer major advantages in terms of speed, precision, and scalability. These machines are designed for high-volume production, making them ideal for businesses expecting to produce large quantities of products. They can operate continuously, reducing the need for human labor and minimizing errors that may occur with manual handling. Additionally, automated machines typically offer a higher level of consistency, ensuring that each product is filled to the exact same level, which is crucial for maintaining product quality and brand reputation.

On the other hand, manual filling machines are more cost-effective and are better suited for smaller-scale operations or businesses that are just starting out. While they may not offer the same speed and consistency as automated machines, they provide more flexibility and control over the filling process. Manual machines also have lower upfront costs, making them a good option for businesses that want to keep initial expenses down or those with limited production volumes.

Cost-Benefit Analysis: Maximizing Productivity and Reducing Costs

When deciding on the right filling machine, conducting a cost-benefit analysis is essential to determine whether automation or manual filling will provide the best return on investment (ROI). While automated machines typically require a higher upfront investment, they often pay off in the long run by increasing production speed and reducing labor costs. Automated machines can handle larger production volumes, resulting in lower cost-per-unit production as compared to manual machines. This can be especially beneficial for businesses looking to scale their operations and meet higher market demands.

However, for businesses with smaller production needs or a limited budget, manual machines might be a more affordable solution initially. While they are slower and require more labor, they offer lower operating costs and can still maintain high product quality. By assessing your production goals, budget, and long-term growth plans, you can determine which option provides the best balance of cost savings and productivity for your business.

Choosing Reliable Suppliers for Your Filling Equipment

Selecting a reliable supplier for your cosmetic filling machine is critical to ensuring you receive high-quality equipment that meets your production needs. Look for vendors that specialize in the cosmetics industry and have a proven track record of providing durable and efficient machines. A good supplier should offer not only quality products but also exceptional customer service and technical support to help with installation, maintenance, and troubleshooting.

Before making a purchase, research customer reviews and testimonials to gauge the reputation of the supplier. Asking for product demos or visiting their facilities can also provide valuable insights into the machine’s performance and reliability. Additionally, consider the supplier’s after-sales service, such as offering training, spare parts, and maintenance packages, which can be critical in minimizing downtime and maximizing the lifespan of your equipment. Working with a trusted supplier ensures that your cosmetic filling machine is a worthwhile investment that will support your business's growth and success.

Conclusion

In conclusion, a cosmetic filling machine is essential for starting and growing a successful cosmetics business. These machines not only enhance production efficiency but also ensure product quality, consistency, and safety. By evaluating product type, production scale, and budget, you can select the right equipment to optimize your operations.

Investing in high-quality filling, capping, labeling, and cleaning equipment will help your business meet industry standards. This will ensure customer satisfaction and keep you competitive in the rapidly growing cosmetics market.

For businesses looking for reliable equipment, Guangzhou Wejing Intelligent Equipment Co., Ltd. offers high-performance solutions, providing value through innovative filling machines and excellent customer service.

FAQ

Q: What is a cosmetic filling machine?

A: A cosmetic filling machine is a device used to accurately fill cosmetic products, such as creams, lotions, and oils, into containers like bottles or tubes. It automates the filling process, ensuring consistency and reducing manual labor.

Q: Why should I use a cosmetic filling machine for my cosmetics business?

A: A cosmetic filling machine improves production efficiency, ensures product consistency, and reduces waste. It is essential for scaling your business while maintaining high-quality standards.

Q: How do I choose the right cosmetic filling machine?

A: When selecting a cosmetic filling machine, consider factors such as your product type (e.g., cream, liquid), production scale, and budget. Match the machine type to your product’s viscosity and packaging requirements.

Q: What are the benefits of using an automatic cosmetic filling machine?

A: Automatic cosmetic filling machines provide faster filling speeds, greater precision, and consistency. They help reduce labor costs and ensure a higher volume of production, which is ideal for larger businesses.

Q: What is the cost of a cosmetic filling machine?

A: The cost of a cosmetic filling machine depends on factors like automation level, production scale, and product type. Prices can range from a few thousand to tens of thousands of dollars.