Ever wondered how your favorite products are neatly packaged? Filling machines are the answer. These essential devices streamline production across industries.

In this post, you'll learn what filling machines are, their importance, and the different types available.

What is a Filling Machine?

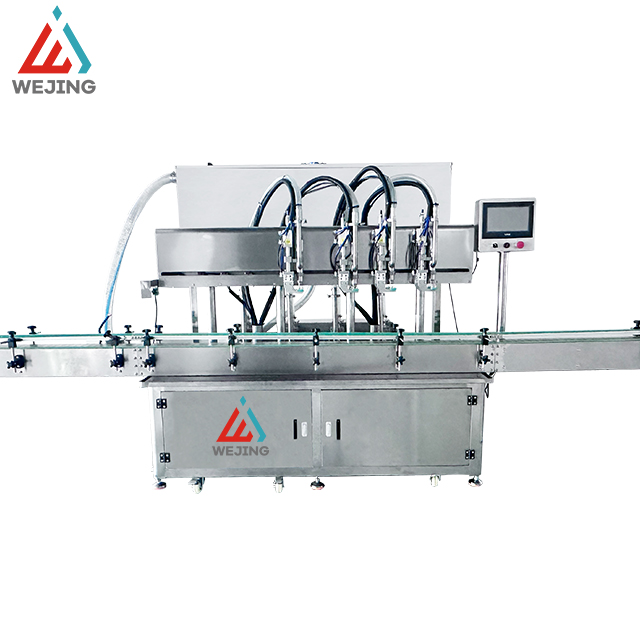

A filling machine is a device that automatically dispenses a precise amount of product into containers. It's designed to streamline the packaging process and ensure consistency in product quantity.

These machines can handle various product forms, such as liquids, powders, granules, and pastes. They fill containers of different shapes and sizes, including bottles, jars, cans, pouches, and more.

Importance in Various Industries

Filling machines play a vital role in numerous industries, such as:

● Food and beverage

● Pharmaceuticals

● Cosmetics

● Chemicals

● Agriculture

They help businesses:

● Increase production efficiency

● Reduce labor costs

● Minimize product waste

● Ensure product quality and consistency

Without these machines, many products we use daily would be difficult to produce on a large scale. They've revolutionized the way companies package and distribute their goods.

How Do Filling Machines Work?

Basic Principles of Filling Machines

Filling machines operate on different principles, depending on the product and container type. The three main principles are:

1. Normal Pressure Filling: This method relies on the product's self-weight to fill containers. It's the simplest and most common principle.

2. High Pressure Filling: In this method, the product is filled under high pressure. It's ideal for viscous products like pastes and creams.

3. Negative Pressure Filling: This technique fills containers in an environment with pressure lower than atmospheric pressure. It's perfect for packaging sensitive or toxic materials.

Different Filling Techniques for Various Products

Filling machines adapt their techniques based on the product's characteristics:

● Liquids with High Fluidity: Free-flowing liquids like water, juices, and oils are often filled using gravity or overflow filling methods. These ensure accurate and fast filling.

● Pastes and Viscous Products: Thick, semi-solid products require piston or pump filling machines. These apply the necessary pressure to dispense the product consistently.

● Toxic or Hazardous Materials: For dangerous substances, enclosed filling systems with negative pressure are used. They prevent leaks and protect both the product and the operator.

Types of Filling Machines

Filling machines come in various types, each designed for specific products and packaging requirements. Let's explore the main categories:

Liquid Filling Machines

● Gravity Filling Machines: They use gravity to dispense liquids into containers. Perfect for thin, free-flowing products like water and juices.

● Piston Filling Machines: These machines use a piston to measure and dispense precise amounts of liquid. Ideal for viscous products like sauces and creams.

● Pump Filling Machines: They employ pumps to transfer liquids from a reservoir into containers. Suitable for a wide range of liquid viscosities.

● Overflow Filling Machines: These machines fill containers to a consistent level, regardless of minor variations in container volume. Great for transparent containers.

● Hot Filling Machines: Designed to handle high-temperature liquids, these machines ensure product sterility and immediate sealing.

● Isobaric Filling Machines: They fill carbonated beverages while maintaining constant pressure, preventing foaming and preserving carbonation.

Powder Filling Machines

● Auger Filling Machines: These machines use a rotating auger to measure and dispense powder products accurately.

● Net Weight Filling Machines: They fill containers based on a specified weight, using load cells or scales for precise measurement.

Granule Filling Machines

● Volumetric Cup Fillers: These machines use cups of specific volumes to measure and dispense granular products.

● Weighing Scale Fillers: Similar to net weight fillers, they use scales to ensure accurate filling of granular products.

● Multi-head Combination Fillers: They combine multiple filling heads, such as augers and scales, to achieve high-speed, precise filling.

Capsule Filling Machines

● Manual Capsule Fillers: These handheld devices allow manual filling of capsules, ideal for small-scale production.

● Semi-automatic Capsule Fillers: They automate parts of the capsule filling process but still require some manual intervention.

● Automatic Capsule Filling Machines: These machines handle the entire capsule filling process, from separating capsules to filling and sealing.

● Softgel Encapsulation Machines: Designed specifically for manufacturing softgel capsules, these machines form, fill, and seal the capsules in a continuous process.

Choosing the Right Filling Machine

Selecting the perfect filling machine for your business can be daunting. But don't worry! We're here to help you make the right choice.

Factors to Consider

When choosing a filling machine, consider these key factors:

● Product Type: Are you filling liquids, powders, or solids? Each requires a specific type of machine.

● Container Type: Will you be using bottles, jars, pouches, or other containers? Make sure the machine is compatible.

● Production Volume and Speed: How much product do you need to fill, and how quickly? This will determine the machine's size and automation level.

● Level of Automation: Do you prefer manual, semi-automatic, or fully automatic machines? Consider your budget and workforce.

Specific Recommendations

● For Startups: If you're just starting out, a semi-automatic machine might be the best choice. They offer a good balance of efficiency and affordability.

● For Established Companies: If you have a high-volume production line, fully automatic machines are the way to go. They provide speed, precision, and consistency.

● For Food and Beverage Industry: Choose machines with easy cleaning features and hygienic design. Consider options like CIP (Clean-in-Place) and SIP (Sterilize-in-Place).

● For Pharmaceutical Industry: Opt for machines with high accuracy and precision. Look for features like dosing control and validation protocols.

Industry | Recommended Machine Type |

Food & Beverage | Hygienic, easy-to-clean |

Pharmaceutical | High accuracy, dosing control |

Cosmetics | Versatile, multi-product |

Chemicals | Safety features, enclosed design |

Benefits of Using Filling Machines

Investing in a filling machine can revolutionize your production process. Here's how:

● Increased Production Speed and Efficiency: Filling machines can work tirelessly, churning out products faster than manual labor ever could. They streamline your production line, boosting output and efficiency.

● Consistent and Accurate Filling: Say goodbye to human error! Filling machines ensure each container receives the exact amount of product, every single time. This consistency is crucial for product quality and customer satisfaction.

● Reduced Product Waste and Spillage: With precise filling mechanisms, these machines minimize product waste and spillage. Less mess means more money saved on raw materials.

● Improved Hygiene and Safety Standards: Automated filling machines reduce human contact with products, enhancing hygiene and safety. This is especially important in food, beverage, and pharmaceutical industries.

● Cost Savings on Labor and Packaging Materials: By automating the filling process, you can reduce labor costs significantly. Plus, accurate filling means using just the right amount of packaging materials, cutting down on waste and expenses.

● Scalability for Business Growth: As your business grows, so can your filling machines. Many models are designed to accommodate increased production demands, allowing you to scale up without breaking the bank.

Investing in a filling machine is a smart move for any business looking to optimize its production process. From increased efficiency to cost savings, these machines offer a wide range of benefits that can help take your operations to the next level.

Maintenance and Troubleshooting

Like any machinery, filling machines require regular maintenance and troubleshooting to keep them running smoothly.

Regular Inspection and Cleaning

● Regular Inspection Schedules: Establish a routine inspection schedule to catch potential issues early. Check for wear and tear, loose parts, and any abnormalities.

● Condition Monitoring: Keep an eye on key indicators like oil levels, vibrations, and temperatures. Changes in these can signal potential problems.

Component | Inspection Frequency |

Oil Levels | Weekly |

Vibrations | Daily |

Temperatures | Hourly |

Preventive Maintenance Schedules

Create a preventive maintenance schedule based on the manufacturer's recommendations and your machine's specific needs. This may include:

● Lubrication

● Filter replacements

● Calibration checks

● Sensor cleaning

Common Issues and Their Solutions

● Clogging and Blockages: Regularly clean and inspect filling nozzles and tubes. Ensure products are free of lumps or foreign objects.

● Leaks and Sealing Problems: Check for worn or damaged seals and gaskets. Replace them as needed. Ensure proper alignment of filling heads and containers.

● Sensor and Control System Malfunctions: Verify sensor calibration and clean any debris. Check wiring and connections for damage or loose contacts.

Spare Parts Management

Keep critical spare parts on hand to minimize downtime during repairs. This may include:

● Filling nozzles

● Seals and gaskets

● Sensors

● Pumps and valves

Operator Training and Safety Protocols

Properly train your operators on machine use, maintenance, and safety procedures. Develop clear safety protocols, including:

● Personal protective equipment (PPE)

● Lockout/tagout procedures

● Emergency stop procedures

● Cleaning and sanitation protocols

Applications of Filling Machines

Filling machines are versatile workhorses, found in nearly every industry that deals with packaged products. Let's explore some of their key applications:

● Food and Beverage Industry: From bottling soft drinks to packaging sauces, filling machines keep our favorite products flowing. They handle a wide range of liquids, pastes, and even chunky mixtures like salsa or coleslaw.

● Pharmaceutical and Cosmetic Products: Precision is paramount when it comes to medicines and personal care items. Filling machines ensure accurate dosing of liquid medications, creams, lotions, and more. They maintain strict hygiene standards to prevent contamination.

● Chemical and Cleaning Products: Whether it's household cleaners, industrial solvents, or car care products, filling machines safely and efficiently package these potentially hazardous substances. They're built to handle corrosive and volatile materials.

● Agricultural and Veterinary Products: From pesticides to pet shampoos, filling machines play a vital role in the agricultural and veterinary sectors. They can handle thick suspensions, granular products, and even paste-like supplements.

● Automotive and Industrial Lubricants: Precise filling is crucial for motor oils, transmission fluids, and other lubricants. Filling machines ensure the right amount of product goes into each bottle, preventing spills and maintaining product consistency.

Industry | Example Products |

Food & Beverage | Soft drinks, sauces, condiments |

Pharmaceutical | Liquid medications, cough syrups |

Cosmetics | Lotions, shampoos, creams |

Chemicals | Detergents, solvents, bleach |

Agriculture | Pesticides, fertilizers, animal supplements |

Automotive | Motor oil, transmission fluid, coolants |

No matter the industry, filling machines adapt to handle the specific products and packaging requirements. From delicate cosmetics to heavy-duty chemicals, these machines keep production lines moving and products flowing into the hands of consumers.

Choosing the Right Filling Machine Manufacturer

Investing in a filling machine is a big decision. Choosing the right manufacturer is just as important as selecting the right machine. Here's what to consider:

Factors to Consider

● Experience and Reputation: Look for a manufacturer with a proven track record in the industry. Check their client testimonials and case studies. A reputable manufacturer will have a history of satisfied customers.

● Product Range and Customization Options: Does the manufacturer offer a wide range of filling machines? Can they customize a machine to fit your specific needs? Versatility and flexibility are key.

● After-sales Support and Service: Your relationship with the manufacturer doesn't end after the sale. Make sure they offer reliable technical support, training, and maintenance services. Prompt and knowledgeable support can save you costly downtime.

● Warranty and Guarantee Terms: A manufacturer who stands behind their products will offer comprehensive warranty and guarantee terms. Look for extended warranties and performance guarantees. They show the manufacturer's confidence in their machines.

Questions to Ask Before Making a Purchase

Before you sign on the dotted line, ask the manufacturer these important questions:

1. What is your experience in manufacturing filling machines for my industry?

2. Can you provide references or case studies of similar projects?

3. What customization options do you offer to meet my specific needs?

4. What kind of after-sales support and training do you provide?

5. What are your warranty terms and what do they cover?

6. What are your lead times for delivery and installation?

7. Can you provide a detailed quote with all costs included?

A reputable filling machine manufacturer will be happy to answer these questions and provide you with all the information you need to make an informed decision. They'll work with you to find the best solution for your business.

Factor | Importance |

Experience | ★★★★★ |

Product Range | ★★★★☆ |

After-sales Support | ★★★★★ |

Warranty Terms | ★★★★☆ |

A filling machine is a long-term investment. Choosing the right manufacturer is just as crucial as choosing the right machine. Take your time, do your research, and don't hesitate to ask questions. The right manufacturer will be a partner in your success.

Wejing understands the importance of finding the perfect filling machine for your business. Our experts are ready to provide personalized recommendations and support to help you make the right choice. Contact us today to discuss your specific needs and let us find your ideal solution.

Conclusion

Filling machines are indispensable tools that streamline packaging processes, ensure product consistency, and boost production efficiency. They've revolutionized the way businesses package and distribute their products, making it possible to meet growing consumer demands.

When choosing a filling machine, consider product type, container, and production needs. Automation level is also crucial for efficiency.

As technology advances, we can expect to see even more innovations in filling machines. From smart sensors and IoT connectivity to eco-friendly packaging solutions, innovations will continue to drive efficiency and sustainability.

By investing in the right filling machine and partnering with a reputable manufacturer, businesses can unlock new levels of efficiency, precision, and growth. Whether you're a small startup or a large-scale enterprise, a filling machine can be the key to taking your production to the next level.