Product Advantage:

1. Accurate and consistent filling for high-quality assurance.

2. Semi-automatic operation design to enhance production efficiency.

3. Integrated filling, capping, and labeling process for smooth and efficient operation.

4. Intuitive and user-friendly interface for straightforward operation and control.

5. Compact and portable structure, suitable for various production locations.

Technical Parameters:

Capacity | 600-1200 cans/hr,depending on filing volume |

Liquid filling capacity | 30-500ml(can be choose) |

Gas filling capacity | 30-500ml(can be choose) |

Filling accuracy | ≤±1% |

Applicable can diameter | 40-70mm |

Suitable aerosol can height | 70-300mm |

Air source | 0.5-0.6Mpa |

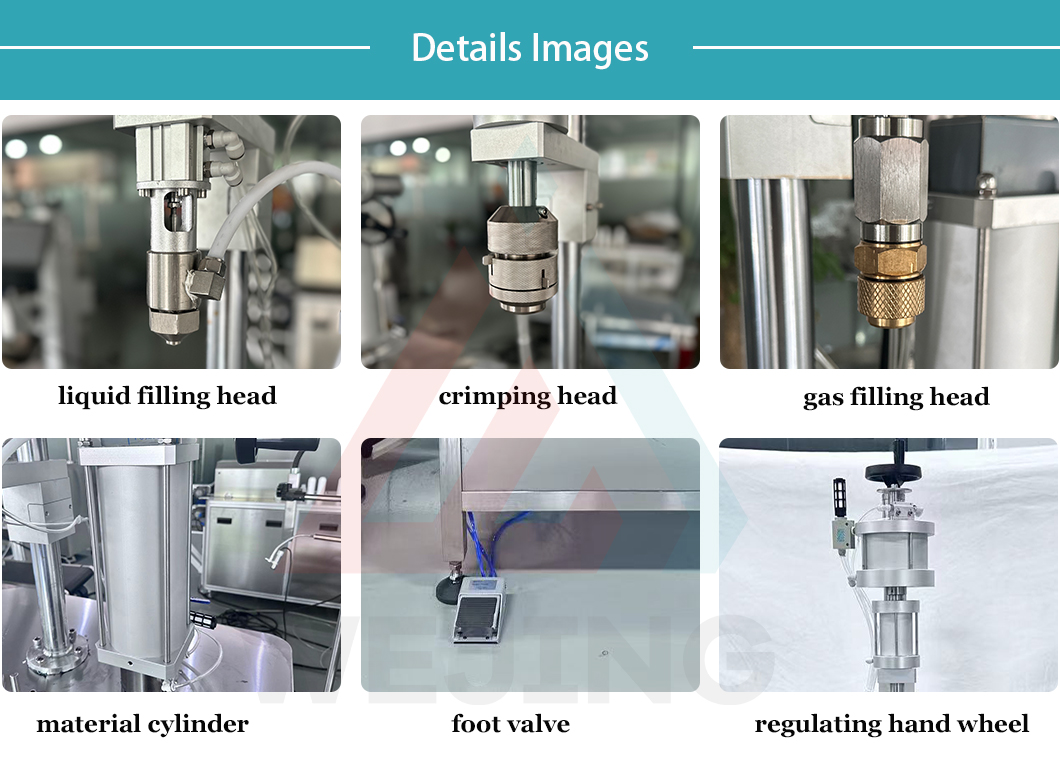

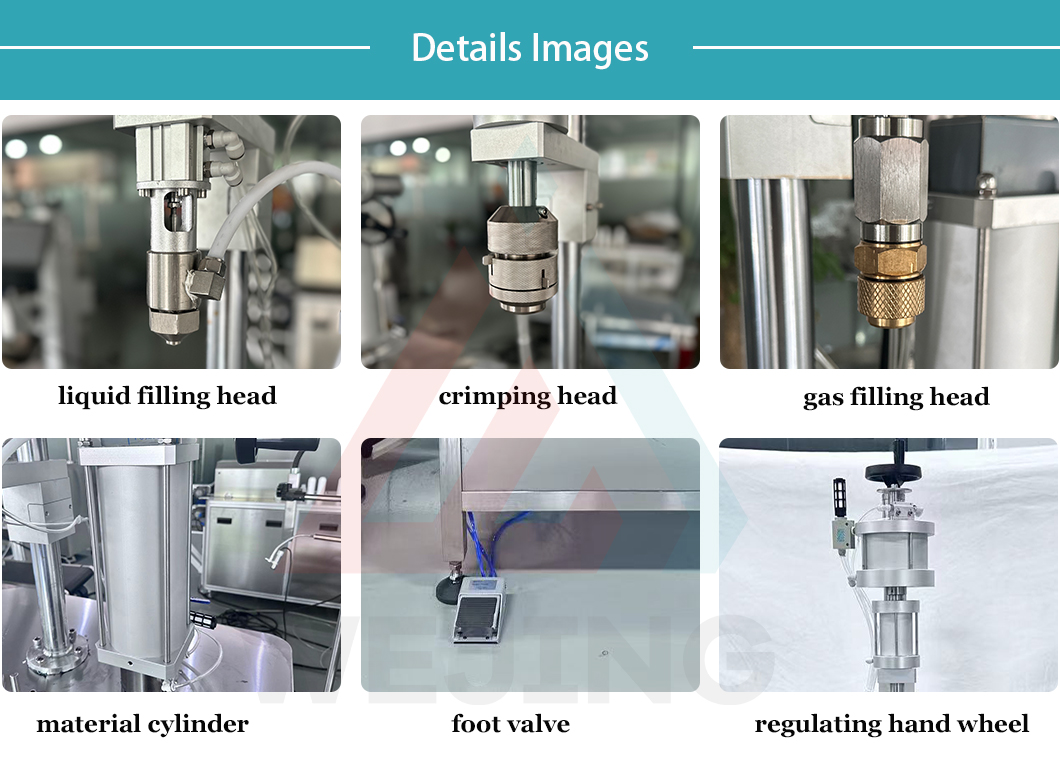

Product Details:

1. The workbench panel is crafted from matte 304 stainless steel plates, with 304 stainless steel being used for the materials in contact with the raw materials. In exceptional cases, 316 stainless steel can be customized.

2. All the remaining stainless steel materials are of the 304 type.

Product Uses:

1. Pharmaceutical Sector: Fills aerosols with medications for nasal sprays and inhalers. Ensures precise dosing and sterile packaging for respiratory treatments and topical drugs.

2. Cosmetic Industry: Packages perfumes, hair sprays, and deodorants in aerosol form. Maintains product integrity and allows for consistent, fine-mist application of beauty products.

3. Household Chemicals: Fills air fresheners, insecticides, and cleaning sprays. Enables efficient packaging of household products for easy consumer use.

4. Automotive Products: Packages tire inflators, lubricants, and car cleaning sprays. Provides consistent filling for automotive maintenance and care products.

5. Industrial Applications: Fills paint sprays, degreasers, and industrial cleaners. Ensures proper pressurization and sealing for professional-grade aerosol products.

6. Food Industry: Packages cooking sprays, whipped cream, and food preservatives. Maintains food safety standards while providing convenient aerosol packaging for culinary use.

7. Personal Care: Fills sunscreens, body sprays, and dry shampoos. Enables even application and proper pressurization for personal hygiene products.

8. DIY and Crafts: Packages spray paints, adhesives, and fabric protectors. Supports hobbyists and craft enthusiasts with precisely filled aerosol products.

9. Sports and Outdoor: Fills insect repellents, cooling sprays, and waterproofing products. Caters to outdoor enthusiasts with conveniently packaged aerosol solutions.

10. Electronics: Packages compressed air dusters and contact cleaners. Supports electronics maintenance with precise, clean aerosol filling.

Operational Principle:

1. Aerosol valve placement: The aerosol valves are automatically placed into the bottles or cans.

2. Product loading: The filling system loads the intended product into the containers via the valve.

3. Pressure regulation: The machine regulates the pressure within the containers to guarantee accurate filling.

4. Weight assessment: It assesses the weight of the filled containers to ensure the precise amount of product is dispensed.

5. Cap or seal: The filled containers are capped or sealed to finish the packaging procedure.

FAQ:

1. By what means does the machine control the filling accuracy?

The machine utilizes precise filling mechanisms and weighing systems to guarantee accurate filling.

2. Is it capable of handling different types of aerosol containers?

Yes, it is engineered to accommodate a wide range of types and sizes of aerosol containers.

3. What is the top filling speed of the machine?

The filling speed can vary depending on the particular model and configuration.

4. Is the machine straightforward to operate and maintain?

Yes, it is generally designed for user-friendly operation and requires minimal upkeep.

5. Does the machine come with a warranty?

The warranty duration and terms may differ by the manufacturer. It is advisable to consult the supplier.