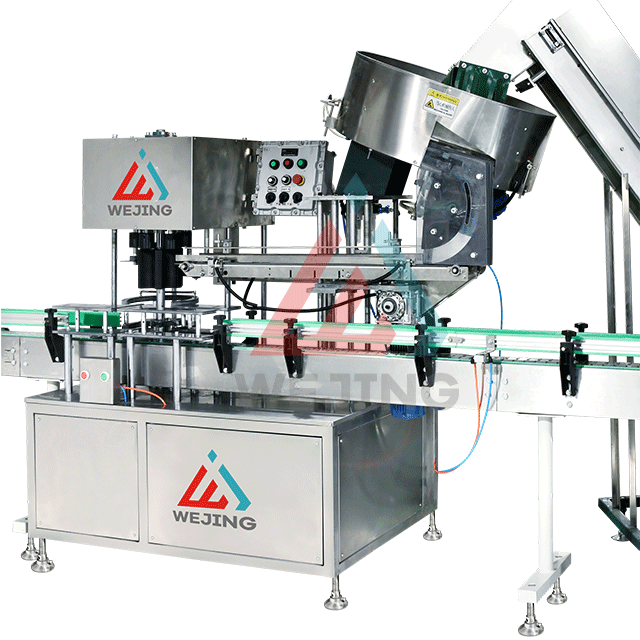

Wejing presents the High Speed Auto Plastic Cap Inserted And Fixed Machine. Our twelve-head rotation system significantly boosts production speed, reducing labor needs. This innovative design ensures stable quality, minimizes losses, and enhances efficiency. Choose Wejing for your high-speed plastic cap insertion needs. Contact us today!

Product Advantage:

1. production speed and less labor.

2. More stable quality and less loss.

3. Adopting twelve head rotation to raise production speed greatly.

Technical Parameters:

Technical Parameter | Description |

Speed | ≥ 120 bottles /min |

Suitable can diameter

| 35-70mm |

Suitable can height | 70-330mm |

Control | Electricity control |

Alarm system | Equipped with uncovered alarm device |

Air source | 0.8Mpa |

Power | 2kW |

Size | 1900*1700*850mm |

Weight | 300kg |

Product Uses:

The equipment is used for the outer plastic cap packaging of aerosol products.

Product Operate Guide:

1. Switch on the power supply.

2. Adjust the parameters according to the product specifications.

3. Load the empty aerosol cans onto the conveyor belt.

4. Activate the machine to insert and fix the plastic caps.

5. Monitor the operation and ensure the quality of the fixed caps.

FAQ:

1. What is the High Speed Auto Plastic Cap Inserted And Fixed Machine for aerosol filling line?

Ans: It is a machine used for automatically inserting and fixing plastic caps on aerosol cans during the filling process.

2. What are the key features of this machine?

Ans: High speed, precision, automation, and efficiency.

3. How does the machine ensure the accuracy of cap insertion?

Ans: Through precise sensors and control systems.

4. Can the machine handle different cap sizes and shapes?

Ans: Yes, it can be adjusted to accommodate various cap sizes and shapes.

5. What is the benefit of using this machine in the production line?

Ans: Increased productivity, reduced labor costs, and improved quality control.