Product Advantage:

1. It boasts high filling accuracy and consistency, guaranteeing that every container is accurately filled with the right amount of the product.

2. The operation is straightforward, allowing operators to quickly learn and operate the machine with minimal training.

3. It demonstrates flexibility in handling different container sizes and shapes, making it suitable for a broad range of applications.

Technical Parameters:

Filling volume | 30-500ml (customized) |

Filling accuracy | ≤±1% |

Filling capacity | 500-1000 Can/hr |

Can body height | 70-330mm,customization available |

Can size | 1 inch |

Air source | 0.45-0.7Mpa |

Air consumption | 0.8m3/min |

Weight | 320kg |

Dimension | 900*550*1300mm |

Product Details:

It fills aerosol containers with products semi-automatically, minimizing the requirement for substantial human involvement.

1. This equipment is used in the aerosol packaging industry.

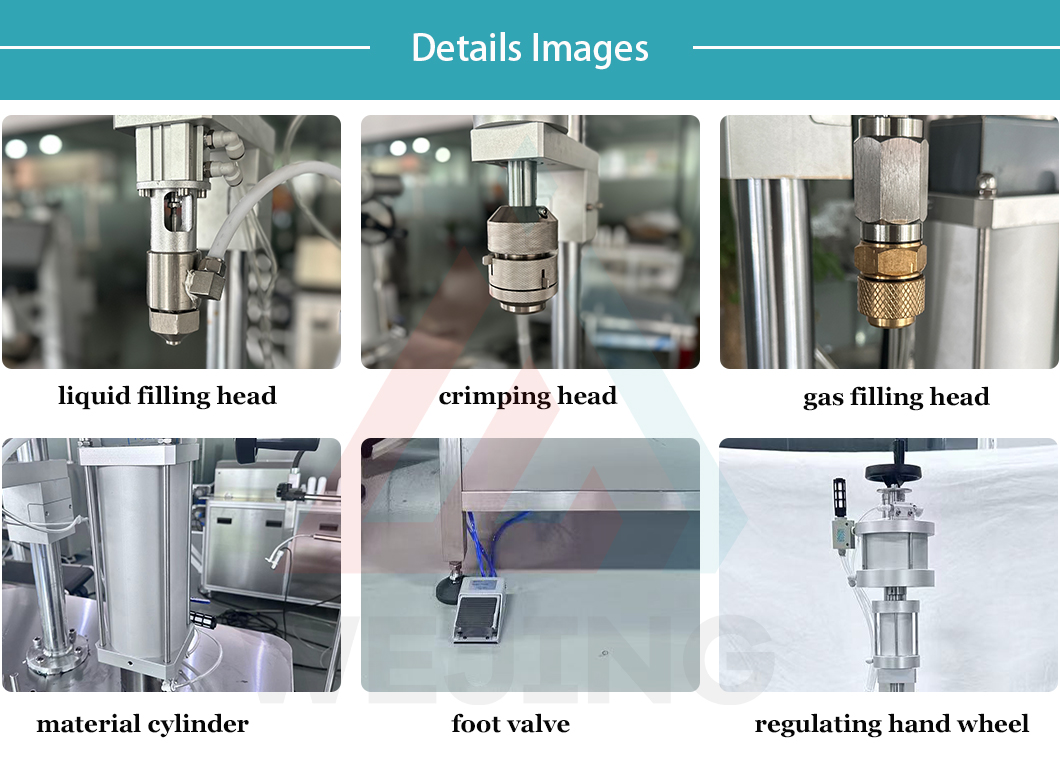

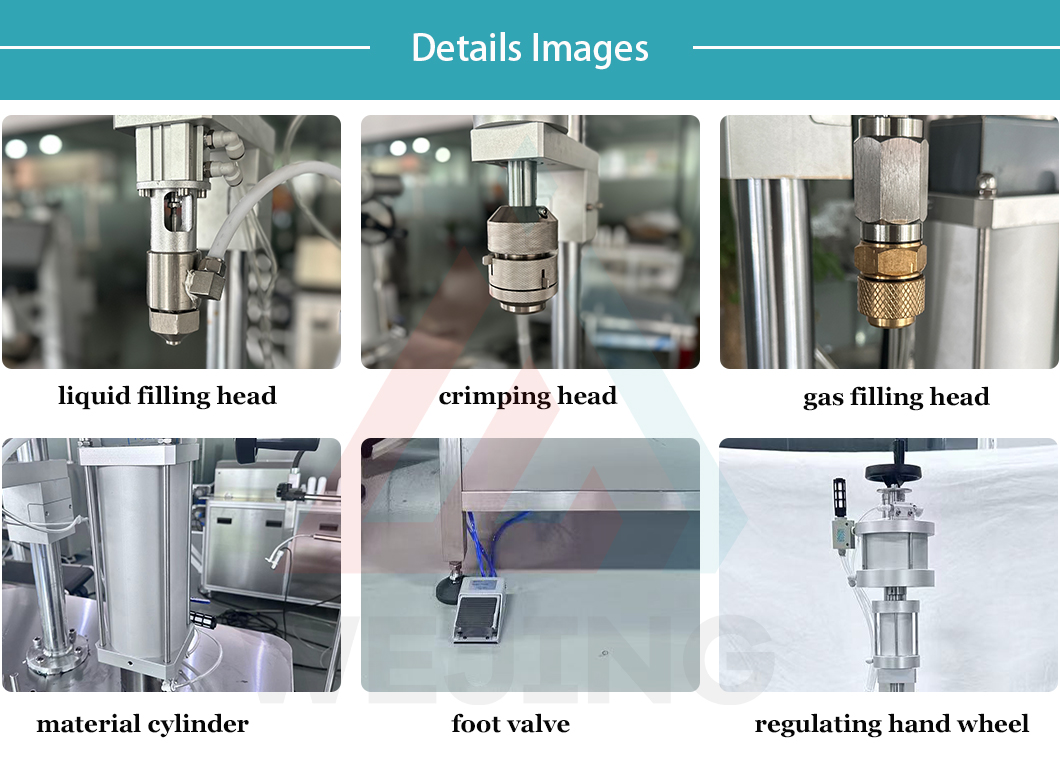

2. It usually consists of several components, such as a filling device, a sealing system, and a control panel.

3. The filling device ensures accurate measurement and distribution of the product into the containers.

4. The sealing system creates a secure and leak-proof seal to maintain the integrity of the aerosol product.

5. The control panel allows operators to monitor and adjust various parameters during the filling process.

6. Compared with manual filling methods, semi-automatic aerosol filling machines offer increased efficiency and productivity.

7. They may be compatible with different types of aerosol containers, including cans or bottles.

8. Proper maintenance and calibration of the machine are essential to ensure consistent and high-quality filling.

Product Uses:

1. It can fill a variety of aerosol items, such as sprays, perfumes, and cleaning solutions.

2. It is applicable to various industries, including cosmetics, household, and automotive.

3. It provides efficient and precise filling, guaranteeing quality and uniformity.

Operational Principle:

1. Automatic filling process: The machine uses a semi-automatic method to fill aerosol containers with precise amounts of products.

2. Pressure adjustment: It keeps the correct pressure throughout the filling process to ensure efficient and safe operation.

3. Sealing system: A sealing mechanism is in place to seal the filled aerosol containers, preventing leaks and maintaining the integrity of the product.

FAQ:

1. What is a semi-automatic aerosol filling machine?

It is a device that fills aerosol containers with products using a semi-automatic process.

2. Why use a semi-auto aerosol filling machine?

It provides higher efficiency, accuracy, and productivity.

3. Can it handle different types of aerosols?

Yes, it is compatible with various types of aerosol products.

4. How does it ensure quality?

By ensuring precise filling and leak-proof sealing.

5. Is it easy to operate and maintain?

Yes, it is user-friendly and requires minimal maintenance.