Product Advantage:

1. This machine running stably, reliably, less failure, longer life

2. Higher efficiency and less labor cost

3. Higher precision, more stable filling quality

4. The main pneumatic element and seal ring apply to international quality product, so it features excellentreliability and abrasion resistance

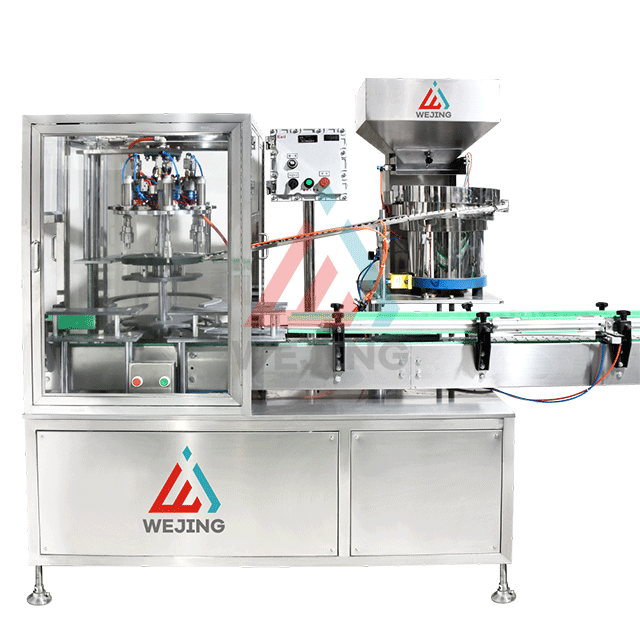

5. The production line conveyor adopts explosion-proofvariable speed motor the rest is driven by co m pressed air, sothe safety is high.

6. One key lifting function, greatly increasing production and changing star wheel speed.

Technical Parameters:

Technical Parameter | Description |

Voltage | 380V/50HZ( can be customized ) |

Dimension(L*W*H) | 22000*4000*2000mm |

Production speed | 130-150 cans/min |

Propellant Type | The type of propellant used in the aerosol product (e.g., LPG, DME, N₂, CO₂, R134a, etc) |

Noise control | ≤80 dB |

Can Type | Tinplate can or aluminum can |

Driven Type | Pneumatic control |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

Filling accuracy | ≤±1% |

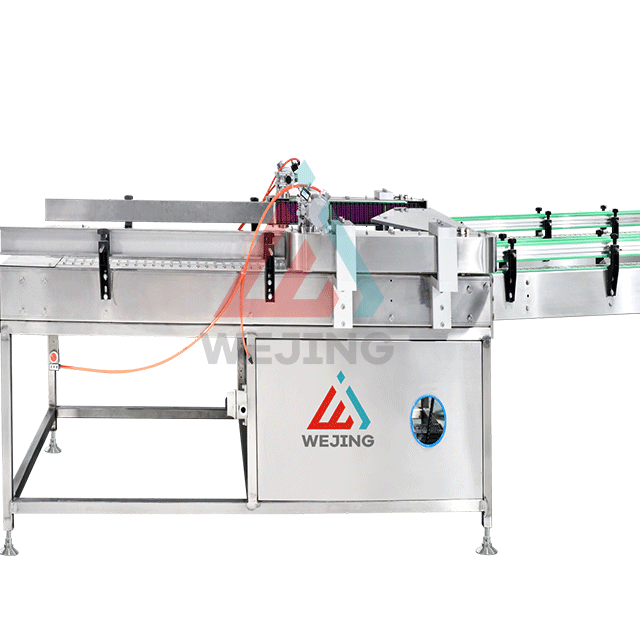

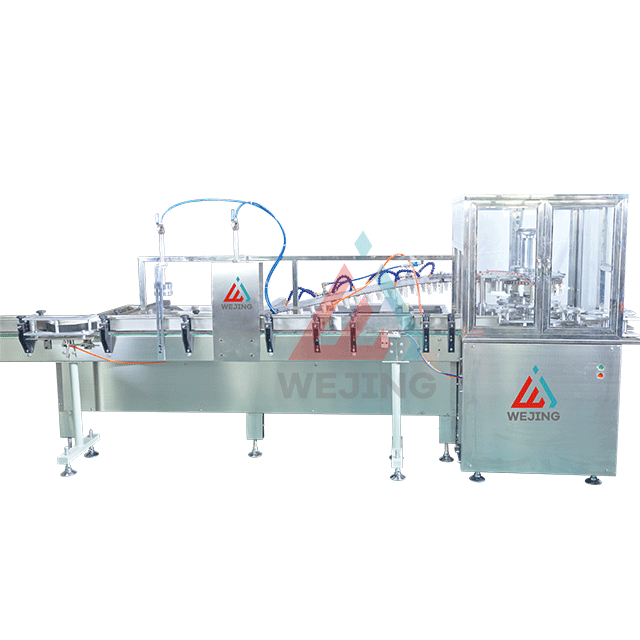

Machine Detailed:

Product Uses:

This production line of high precision and high efficiency features, it can fil internationally applicable oneinch tinplate and aluminum can. It also applies to fill oil water, latex solvent and other middle-viscositysimilar matter, and applies to fill DME,LPG, 134a, N2, CO2 and several propellants, and also used to fill withliquid in chemical engineering, cosmetic, foodstuff and medical industry.

Product Operate Guide:

1. Prepare materials: Ensure that the aerosol cans and propellants are of the correct type and quantity.

2. Adjust settings: Set the filling speed, pressure, and temperature according to the product specifications.

3. Start the production line: Activate the equipment and monitor the operation to ensure everything runs smoothly.

4. Inspect the filled aerosols: Check for leaks, proper fill levels, and any defects.

5. Clean and maintain the equipment: Regularly clean and lubricate the production line to prolong its lifespan.

FAQ:

1. What is the production capacity of the High Speed Aerosol Filling Production Line?

The production capacity depends on the specific model and configuration, but it can range from several hundred to thousands of cans per hour.

2. Can the production line handle different can sizes and shapes?

Yes, the High Speed Aerosol Filling Production Line is designed to handle a variety of can sizes and shapes, with adjustments made to the equipment as needed.

3. Is the filling process automated?

Yes, the filling process is automated, ensuring precise and consistent filling of each can.

4. How is quality control ensured during the production process?

The production line incorporates quality control measures such as weight checking and leak detection to ensure that each filled can meets the required standards.

5. Can the production line be customized to meet specific requirements?

Yes, many High Speed Aerosol Filling Production Lines can be customized and tailored to meet the unique needs and specifications of the customer.