Product Advantage

1. High efficiency and speed: It can feed cans automatically at a high speed, improving production efficiency.

2. Precise control: Equipped with a precise control system, it ensures accurate and consistent feeding.

3. Easy to operate and maintain: Simple interface and easy-to-replace parts for convenient operation and maintenance.

4. Versatile applications: Suitable for various can sizes and shapes, meeting different production needs.

5. High safety standards: Designed with safety protection devices to ensure operator safety.

Technical Parameters

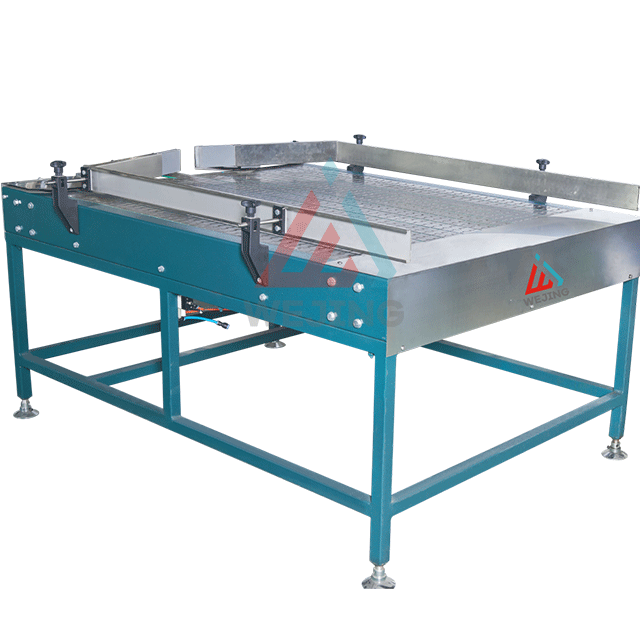

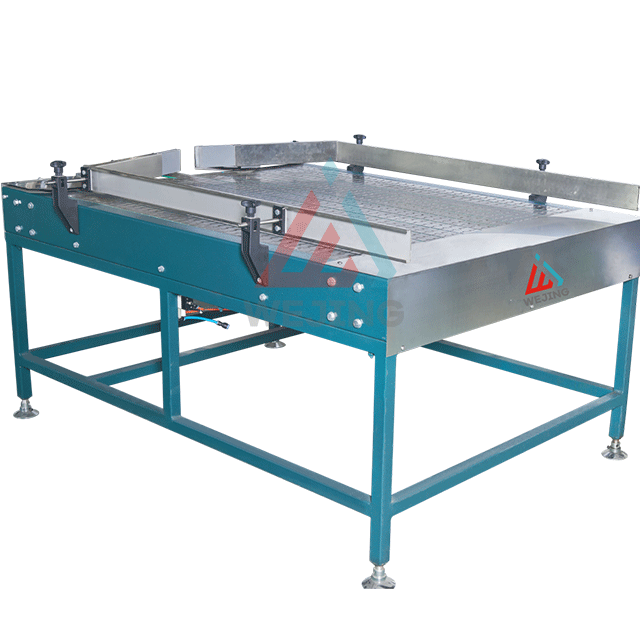

Can Feeding Machine:

Speed (cans/min)

| 60-70cans/min |

Applicable cans diameter (mm) | 40-65 ( can be customized) |

Applicable cans height (mm) | 70-300 ( can be customized) |

Voltage | AC 380V/50HZ |

Air source | 0.6-0.7Mpa |

Power | 0.55kw |

Speed range | 4.52r/min |

Overall size | 2000*1280mm |

Stainless steel plate | 1.2mm thick 304 GB |

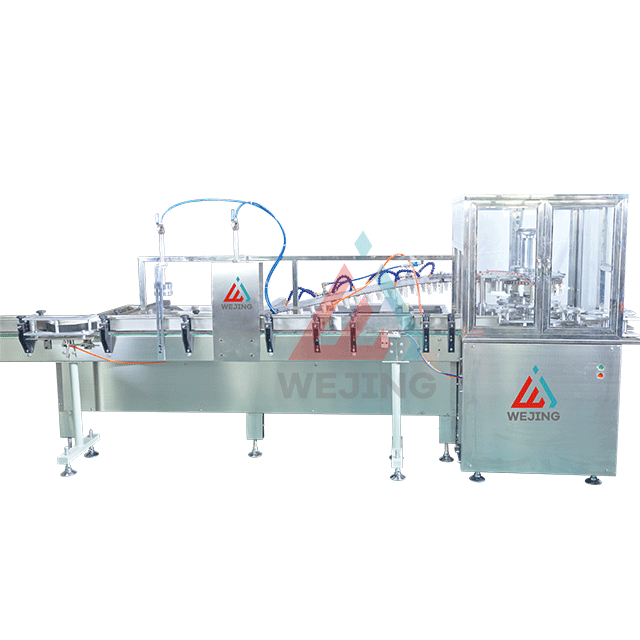

Aerosol Filling line:

Technical Parameter | Description |

Filling capacity (cans/min) | 60-70 |

Liquid filling volume (ml) | 10-1200( can be customized) |

Gas filling volume (ml) | 10-1200( can be customized) |

Filling heads | 4 heads |

Filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35 - 70( can be customized) |

Applicable cans height (mm) | 80 - 300( can be customized) |

Applicable valve | 1 inch |

Working pressure (Mpa) | 0.6 - 0.8 |

Max gas consumption (m3/min) | 5 |

Power (KW) | 7.5 |

Dimension (LWH) mm | 22000*3500*2000 |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

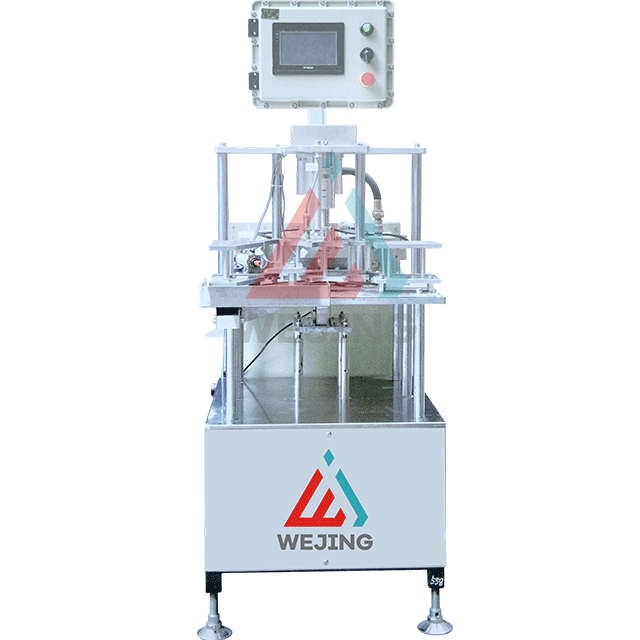

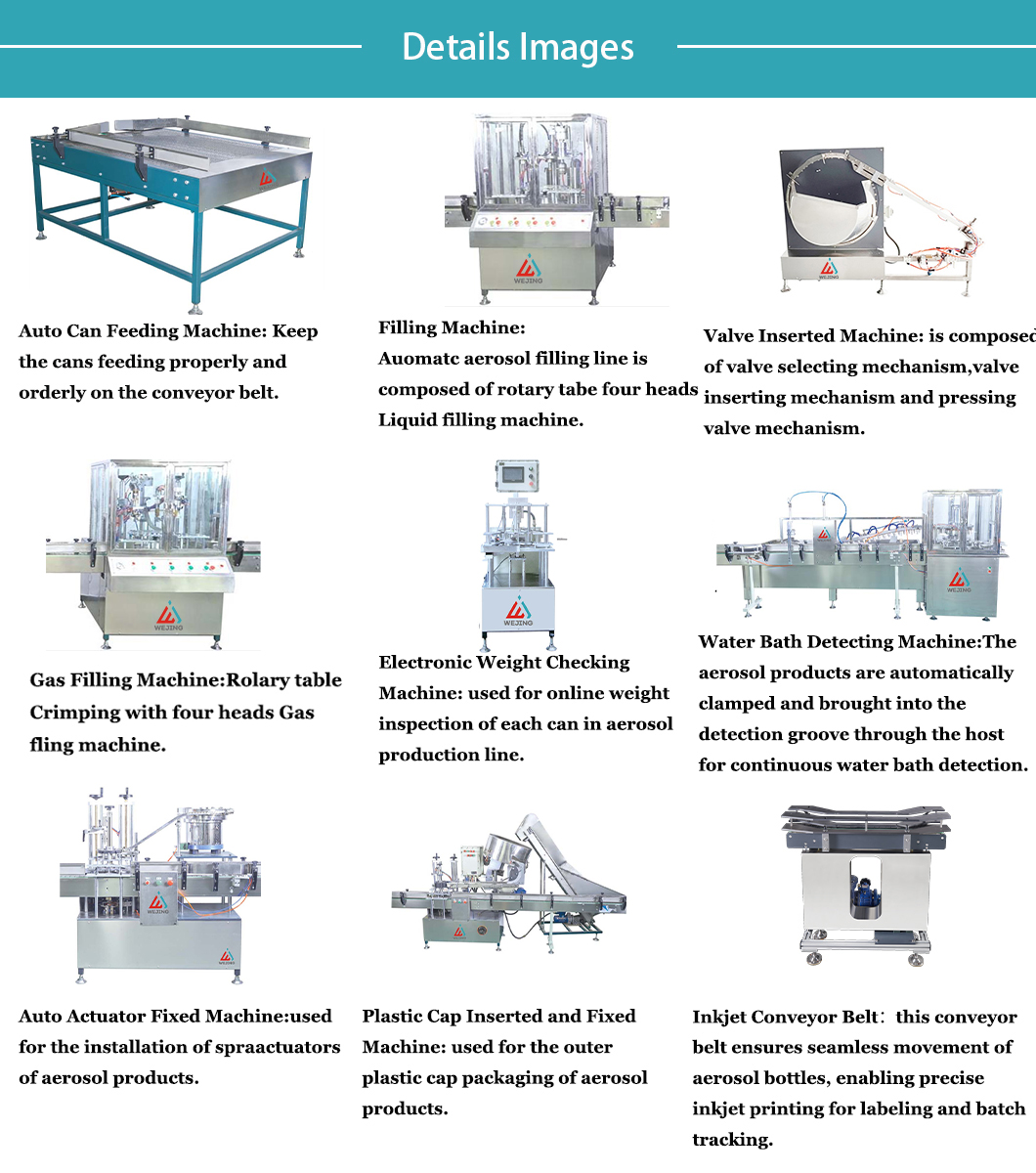

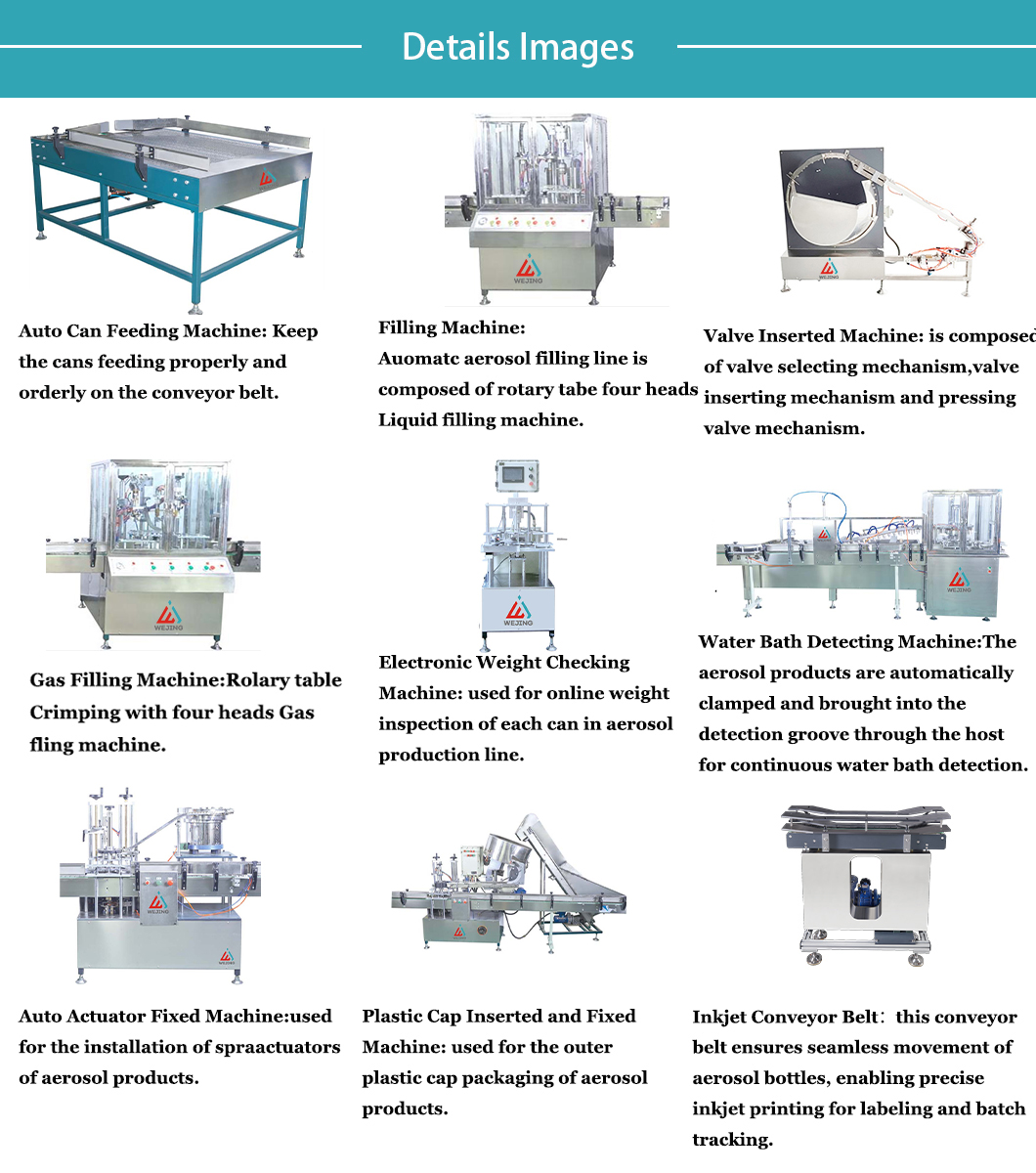

Detailed Images:

Product Uses

1. Automatic can feeding for aerosol filling lines.

2. Increasing production efficiency and reducing labor costs.

3. Ensuring precise and consistent can feeding.

4. Suitable for different can sizes and shapes.

5. Compatible with various aerosol filling line systems.

Product Operate Guide

1. Prepare the cans and ensure they are properly aligned.

2. Turn on the machine and adjust the settings as needed.

3. Load the cans into the feeding mechanism.

4. Monitor the feeding process and address any issues.

5. Regularly clean and maintain the machine for optimal performance.

FAQ

1. What is the Auto Can Feeding Machine For Aerosol Filling Line? It is a machine used to automatically feed cans to the aerosol filling line.

2. What are the advantages of using this machine? It improves production efficiency, ensures precise control, and is easy to operate and maintain.

3. Is it suitable for different can sizes and shapes?

Yes, it is designed to handle various can sizes and shapes.

4. How does it ensure operator safety?

It is equipped with safety protection devices to ensure operator safety.

5. Can it be customized according to specific production needs?

Yes, it can be customized to meet different production requirements.