Product Advantages:

1. Speed: Swift, uninterrupted filling procedures abbreviate production timelines, amplifying output capacity.

2. Precision: Sophisticated dosing methods secure uniform fill masses/volumes, optimizing product efficacy.

3. Adaptability: Accommodates a gamut of can dimensions, configurations, and product compositions – foam, liquid, powder, et al.

4. Sanitation: Stainless steel fabrication, CIP systems, HEPA filters uphold rigorous cleanliness benchmarks.

5. Protection: Progressive pressure regulation, leak identification, and emergency shutdown mechanisms curtail accident risks.

6. Economy: Minimizes waste, slashes labor expenses, and bolsters overall operational thriftiness.

7. Tailorability: Modular blueprint enables facile enhancements, extensions, and fusion with pre-existing gear.

8. Environmental Responsibility: Energy-saving operation, reusable materials, and curtailed discharges foster eco-conscious manufacturing.

9. Usability: Intuitive HMI, automated setup tuning, and minimal operator meddling streamline operation.

10. Tracibility: Embedded data recording, batch monitoring, and serialization tools fortify quality assurance and regulatory conformity.

Technical Parameters:

Technical Parameter | Description |

Filling capacity (cans/min) | 60-70 |

Liquid filling volume (ml) | 10-1200( can be customized) |

Gas filling volume (ml) | 10-1200( can be customized) |

Filling heads | 4 heads |

Filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35 - 70( can be customized) |

Applicable cans height (mm) | 80 - 300( can be customized) |

Applicable valve | 1 inch |

Working pressure (Mpa) | 0.6 - 0.8 |

Max gas consumption (m3/min) | 5 |

Power (KW) | 7.5 |

Dimension (LWH) mm | 22000*3500*2000 |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

Product Uses:

1. Personal Care: Accelerates production of perfumes, antiperspirants, moisturizers, maintaining precise dosing and aseptic environments.

2. Homecare/Cleaning: Effectively encapsulates room fresheners, cleansers, bug sprays, ensuring uniform spritz patterns and potency.

3. Pharmaceutical/Medical: Critical for packaging inhalers, salves, sanitizers; guarantees accurate dosing, sterility to safeguard patients.

4. Food/Beverage: Food-compatible machines encase whipped cream, cooking sprays, flavorings; complies with safety norms, preserves flavors.

5. Automotive/Engineering: Fills oils, degreasants, corrosion preventatives; ensures exact doses, product stability for peak function.

6. Agriculture/Horticulture: Encapsulates pesticides, fungicides, growth promoters; promotes uniform application, aids crop cultivation.

7. Art/Craft Supplies: Fills paint sprays, glues, texturizers; guarantees uniform thickness, hue, precise delivery for professional outcomes.

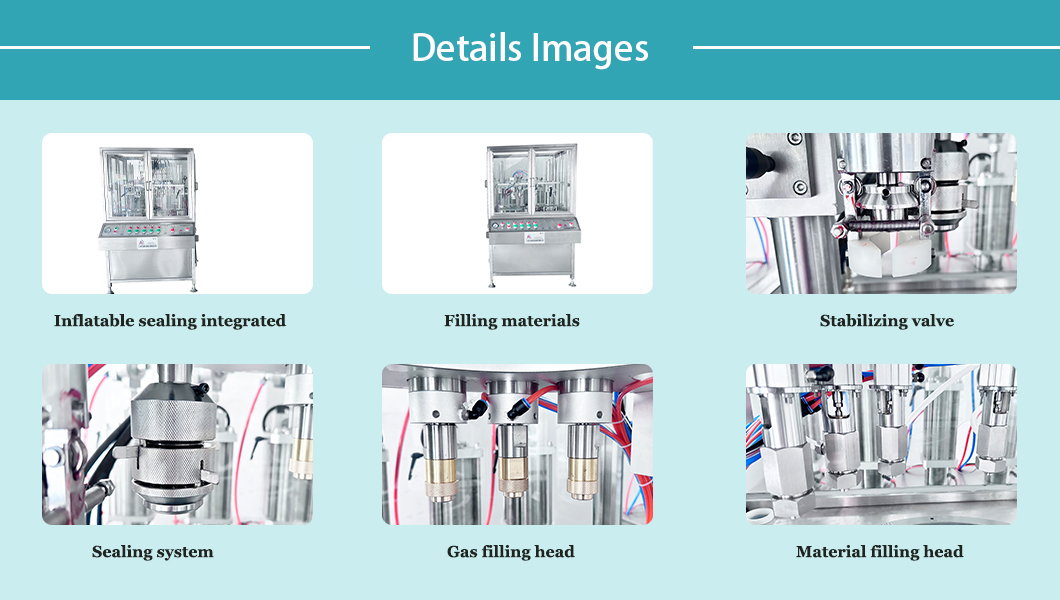

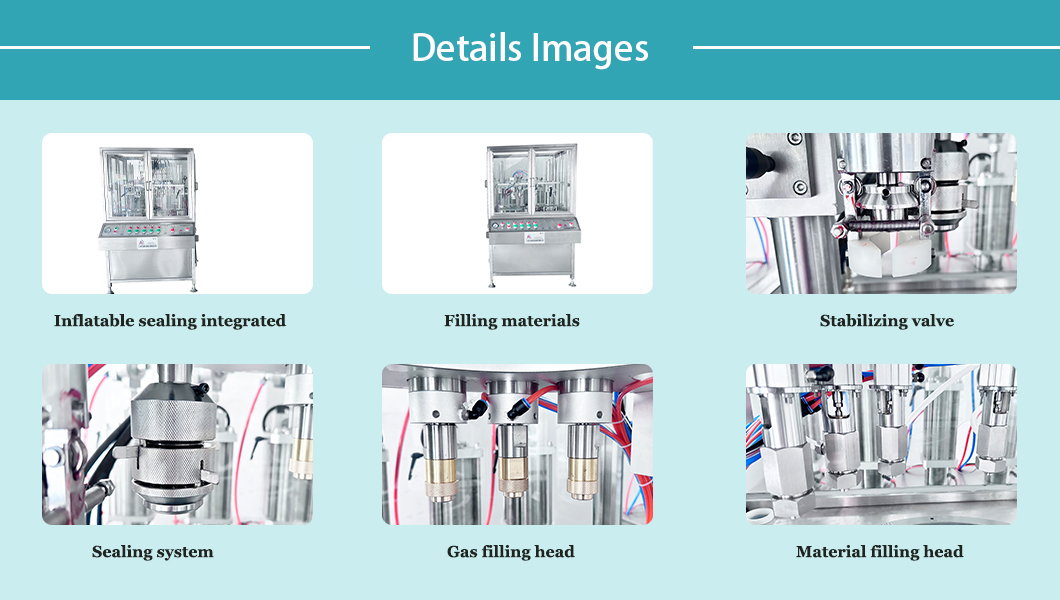

Detailed Images:

FAQ:

1. How does an automatic aerosol filler enhance product excellence?

By consistently administering exact doses, preserving ideal internal pressure, and securing proper seals, it boosts product uniformity, effectiveness, and longevity.

2. Can an automatic aerosol filler manage various product categories concurrently?

Affirmative, thanks to swift changeover attributes and adaptable filling nozzles, it can transition adeptly between distinct recipes and packaging formats.

3. How does the equipment preserve sanitation during filling procedures?

Via utilization of stainless steel fabrication, CIP systems, and HEPA filtration, it diminishes contamination hazards and adheres stringently to cleanliness norms.

4. What is the standard output pace of an automatic aerosol filler?

Subject to the model and setup, devices can populate anywhere from a few hundred to multiple thousand cans per hour, presenting flexible production capabilities.

5. Are automatic aerosol fillers modifiable to fulfill unique production requisites?

Indeed, they can be fine-tuned with supplementary elements, such as labeling, coding, or examination systems, to align with individual client preferences and blend effortlessly into prevailing production chains.