2024.6.12 update

Configuration:

1. Automated Can Infeed System

2. Rapid Liquid Filling Machinery

3. Valve Insertion Automation Unit

4. High-Speed Crimping & Valve Alignment Device

5. Comprehensive Gas Charging Equipment

6. Swift Weight Verification Station

7. Actuator Placement Mechanism (Automatic)

8. High-velocity Cap Application Machine

9. Packaging Assembly Table

Technical Parameters:

Technical Parameter | Description |

Voltage | 380V/50HZ( can be customized ) |

Dimension(L*W*H) | 22000*4000*2000mm |

Production speed | 130-150 cans/min |

Propellant Type | The type of propellant used in the aerosol product (e.g., LPG, DME, N₂, CO₂, R134a, etc) |

Noise control | ≤80 dB |

Can Type | Tinplate can or aluminum can |

Driven Type | Pneumatic control |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

Filling accuracy | ≤±1% |

Detailed Images:

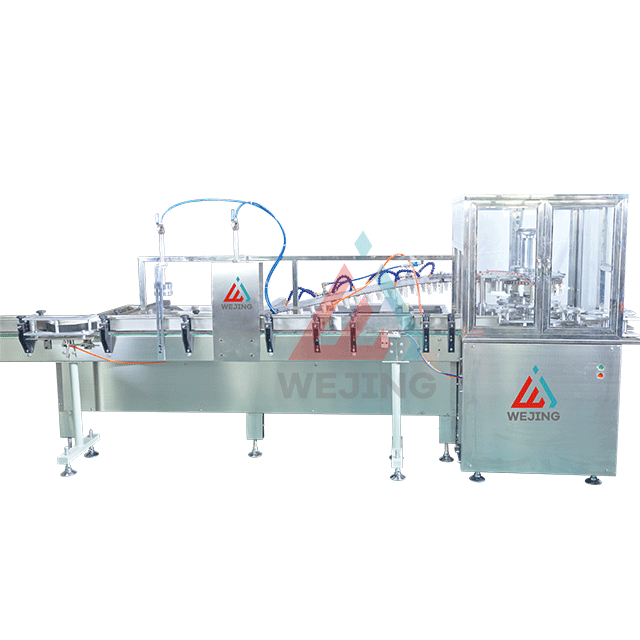

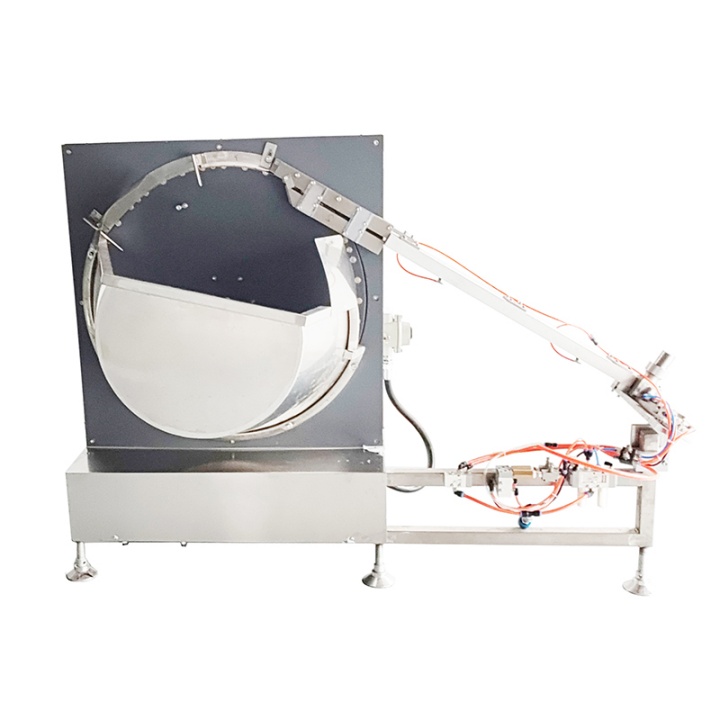

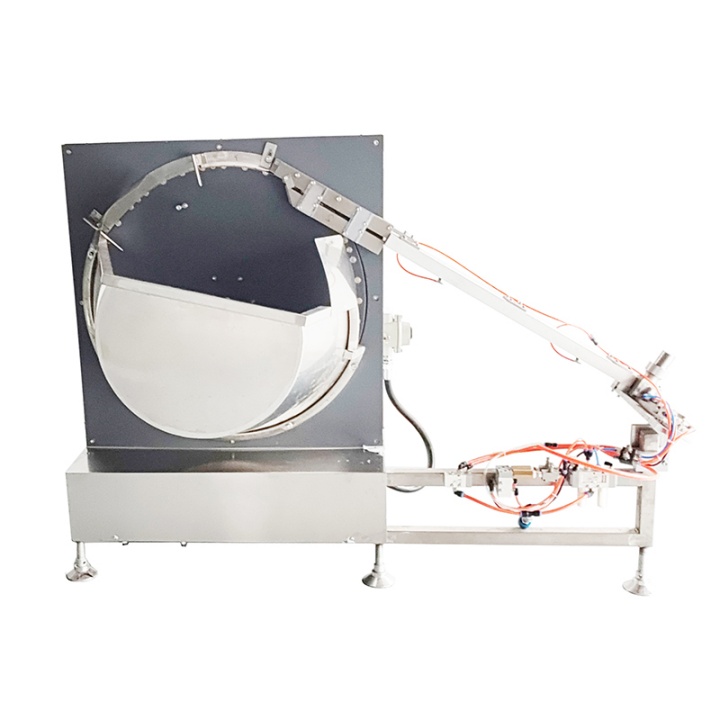

Can feeding Machine:

In the production of aerosol goods, swift operation typically commences with the cans being swiftly fed via an automatic system. To facilitate rapid movement, the machine employs 13 level-conveyor belts powered by an explosion-proof motor, allowing operators to customize the transportation pace according to their requirements.

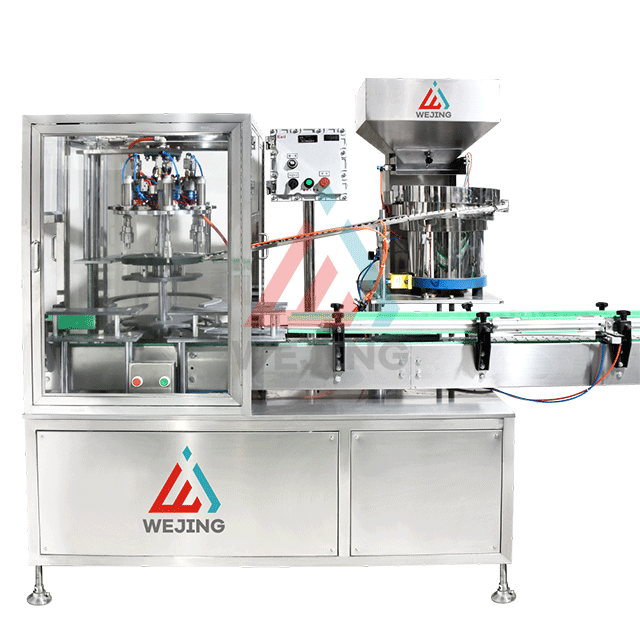

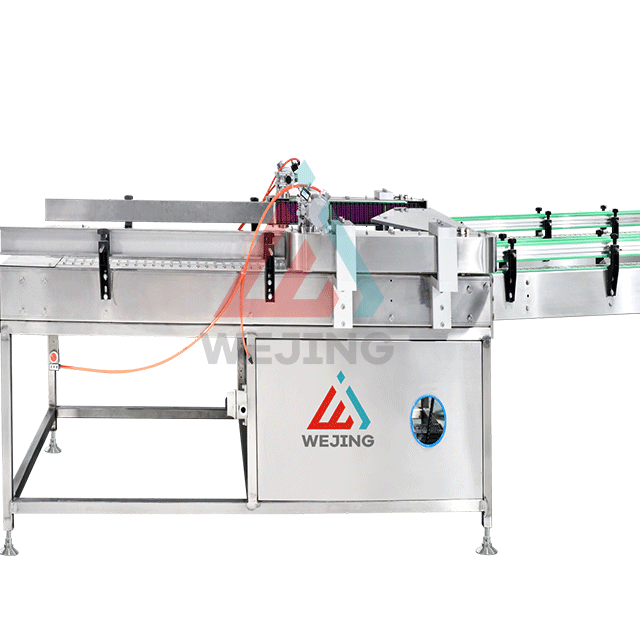

Weight checking machine:

This high-performance Automatic Aerosol Weight Checking Machine is built around a steadfast and highly responsive weighing sensor coupled with a cutting-edge signal detection device, all orchestrated by a PLC for rapid processing.

In the event of consecutive incorrect weights, the machine promptly ceases operation and triggers an alarm, thereby curbing the production of faulty products during the filling process.

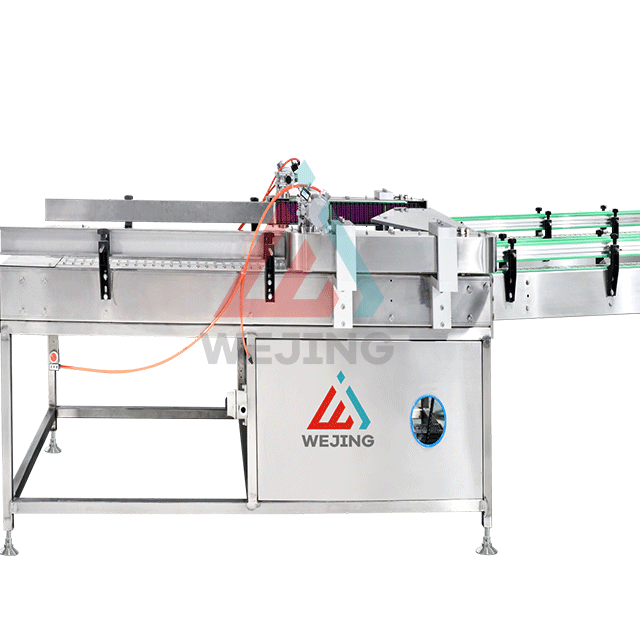

Auto valve inserting machine:

The Actuator Installation Machine comes with a 108-liter hopper and a vibratory sorter that enables automatic shutdown when actuators, cans, or the can-filling stage is depleted. This vibration-based sorter continually monitors and tops up the supply of actuators, facilitating autonomous operation.

The spacious hopper has a capacity to hold approximately 15,000 actuators. The integrated vibratory sorter maintains a consistent supply level through automatic replenishment.

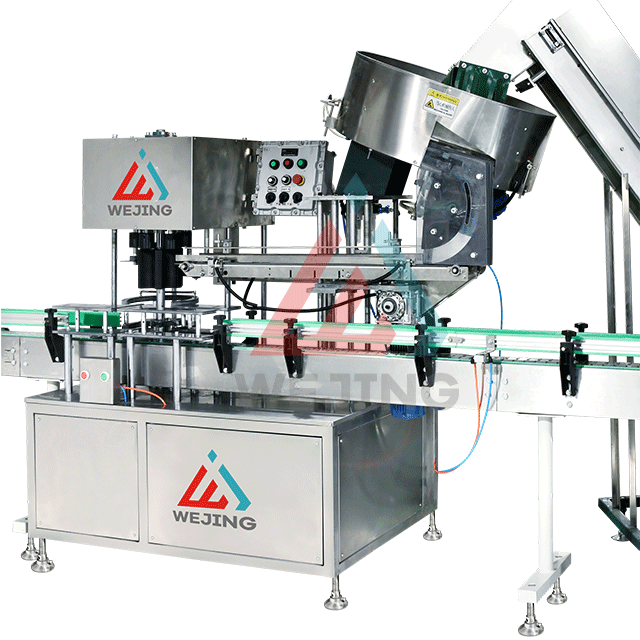

Auto cap presser machine:

This high-speed Automatic Cap Sealing Machine consists of four integral modules: cap feeding, cap alignment, cap rotation, and capping. It includes protective measures against issues such as air deficiency, can jams, and cap jams; upon detecting these faults, clear error messages are displayed on the screen for effortless troubleshooting.

Products:

The High-Speed Aerosol Filling Machine finds application in several industries and product categories. Here are three key areas:

1. Personal Care Industry: High-speed aerosol filling machines are widely used in the production of personal care products such as deodorants, hair sprays, body mists, shaving creams, and other aerosol-based cosmetics, providing efficient and hygienic packaging solutions.

2. Home Care and Household Products: These machines are instrumental in filling and packaging household cleaning agents like air fresheners, insecticides, disinfectant sprays, furniture polish, and oven cleaners, enabling high throughput and consistent product quality.

3. Pharmaceuticals and Medical Devices: In the pharmaceutical sector, high-speed aerosol filling technology is employed for the manufacture of metered-dose inhalers, topical medications, and sanitizing sprays, necessitating precise dosing and adherence to strict regulatory standards.

Additionally, they are also utilized in sectors including automotive (e.g., brake cleaner, lubricants), food and beverage (e.g., whipped cream dispensers), and industrial applications (e.g., adhesives, paints).

FAQ:

Q: What types of products can an automatic aerosol filling machine handle?

A: It can handle a wide range of aerosol products, including personal care items, home care sprays, and pharmaceuticals.

Q: Is an automatic aerosol filler suitable for all can sizes?

A: Yes, most models can accommodate various can sizes, though adjustments may be required.

Q: How does it ensure accurate filling?

A: Using precision valves, sensors, and PLC control systems to measure and regulate product flow.

Q: Are automatic filling machines safe to use with flammable products?

A: Yes, provided they're explosion-proof certified and equipped with proper safety features.

Q: Can it detect and reject under/over-filled cans?

A: Some models include weight-checking systems that can identify and remove non-compliant cans.