Product Advantage

1. High speed and efficiency: It can feed cans at a high speed, greatly improving production efficiency.

2. Precise and reliable: This machine ensures accurate and consistent feeding, minimizing errors and enhancing quality.

3. Automated operation: The automated feature reduces the need for manual labor, increasing productivity and reducing labor costs.

4. Easy to operate and maintain: Its user-friendly design and simple interface make it easy for operators to use and maintain the machine.

5. Flexible customization: This machine can be customized and tailored to meet specific requirements and production processes of different customers.

Technical Parameters

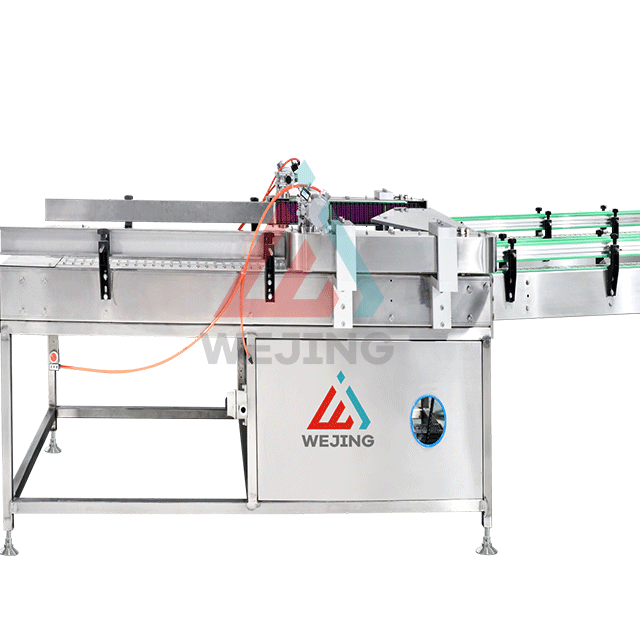

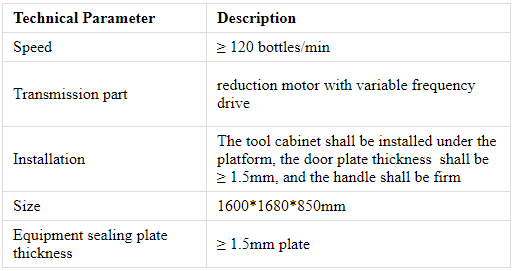

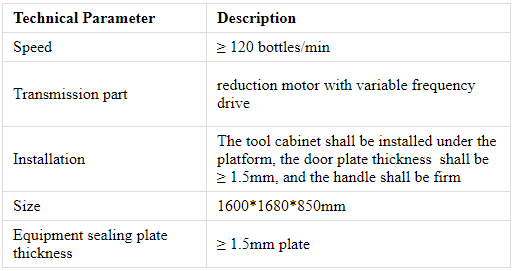

High speed can feeding machine:

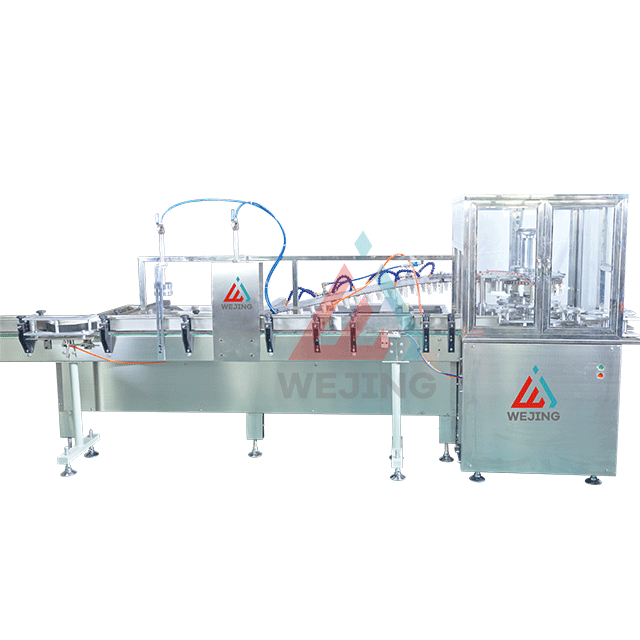

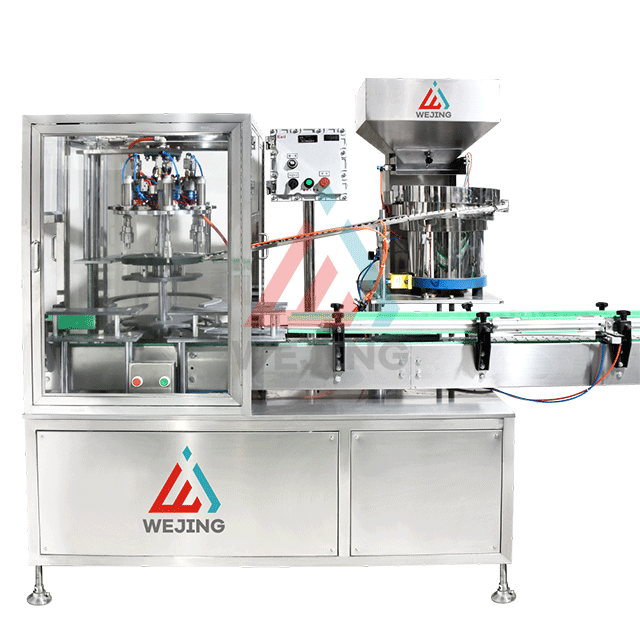

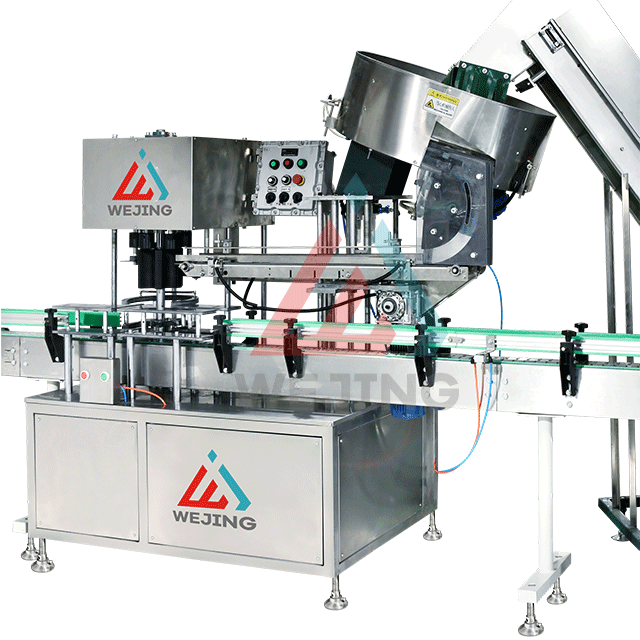

High speed aerosol filling line :

Technical Parameter | Description |

Voltage | 380V/50HZ( can be customized ) |

Dimension(L*W*H) | 22000*4000*2000mm |

Production speed | 130-150 cans/min |

Propellant Type | The type of propellant used in the aerosol product (e.g., LPG, DME, N₂, CO₂, R134a, etc) |

Noise control | ≤80 dB |

Can Type | Tinplate can or aluminum can |

Driven Type | Pneumatic control |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

Filling accuracy | ≤±1% |

Product Uses

1. Automated can feeding in the production line, improving efficiency and reducing labor costs.

2. Suitable for high-speed can packaging processes in various industries, such as food, beverage, and chemical.

3. Enables precise and consistent can positioning, ensuring accurate filling and labeling.

4. Helps to increase production capacity and meet the demands of high-volume production.

5. Customizable to fit specific production requirements and can be integrated into existing lines.

Product Operate Guide

1. Prepare cans: Ensure that the cans are of the correct size and shape for the feeding machine.

2. Load cans: Place the cans in the feeding hopper or conveyor of the machine.

3. Adjust Settings: Set the appropriate speed and feeding parameters according to the production requirements.

4. Start the Machine: Activate the feeding machine and monitor its operation.

5. Inspect and Maintenance: Regularly inspect the machine for any malfunctions or wear and perform necessary maintenance.

FAQ

1. What is the High Speed Auto Can Feeding Machine?

Ans: It is a machine used for automatically feeding cans in a production line at high speeds.

2. What are the benefits of using this machine?

Ans: It increases efficiency, reduces labor costs, and enhances accuracy and consistency in can feeding.

3. Can it handle different sizes and shapes of cans?

Ans: Yes, it is designed to handle a variety of can sizes and shapes.

4. How does the machine ensure precise can feeding?

Ans: It uses sensors and control systems to ensure accurate and consistent can feeding.

5. Is it easy to operate and maintain the machine?

Ans: Yes, it has a user-friendly interface and requires minimal maintenance.