2024.6.12 update

Configuration:-

1. Automated Container Supply System

2. Speedy Fluid Dispensing Equipment

3. Valve Integration Automation Module

4. High-Speed Sealing & Valve Positioning Apparatus

5. All-Inclusive Propellant Charging Solution

6. Prompt Mass Measurement Station

7. Motorized Actuator Mounter

8. Rapid Cap Attachment Device

9. Final Packaging Preparation Table

Technical Parameters:

Technical Parameter | Description |

Filling capacity (cans/min) | 90-120 cans/min |

Filling volume (ml) | 30-1200ml |

Filling accuracy | ≤±1% |

Applicable cans diameter (mm) | 35 - 70( can be customized) |

Applicable cans height (mm) | 80 - 350( can be customized) |

Applicable valve (mm) | 1 inch ( can be customized) |

Working pressure (Mpa) | 0.6 - 1 |

Max gas consumption (m3/min) | 6.4 |

Power (KW) | 45 |

Dimension (LWH) mm | 30500*4800*2550 |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

Detailed Images:

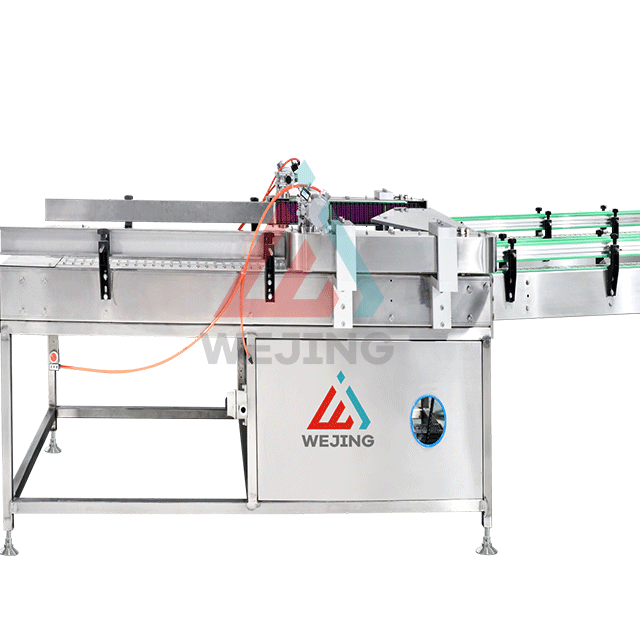

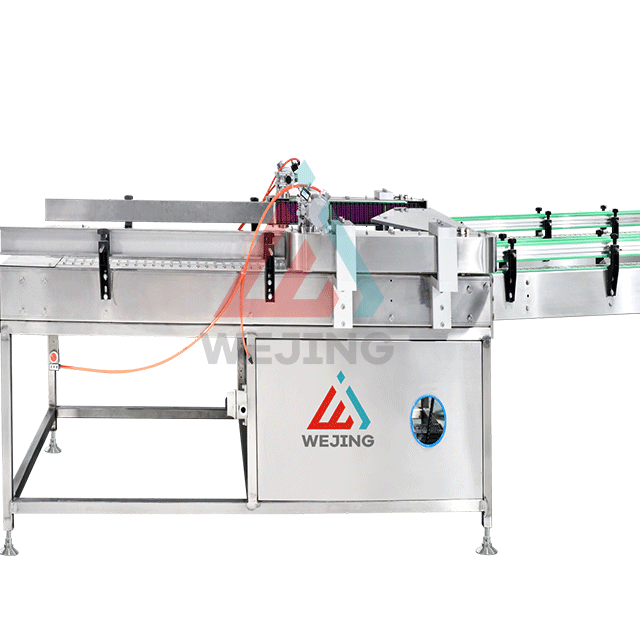

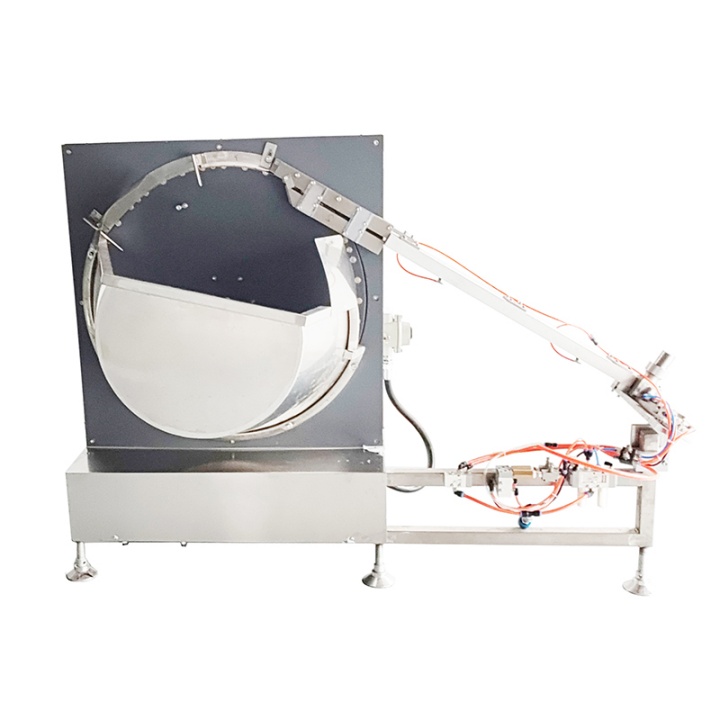

Can feeding Machine:

This particular Automatic Can Alignment Machinery boasts 13 belts with consistently smooth motion and uniform velocity, thereby ensuring stability and precise speed control for the cans throughout the conveying process.

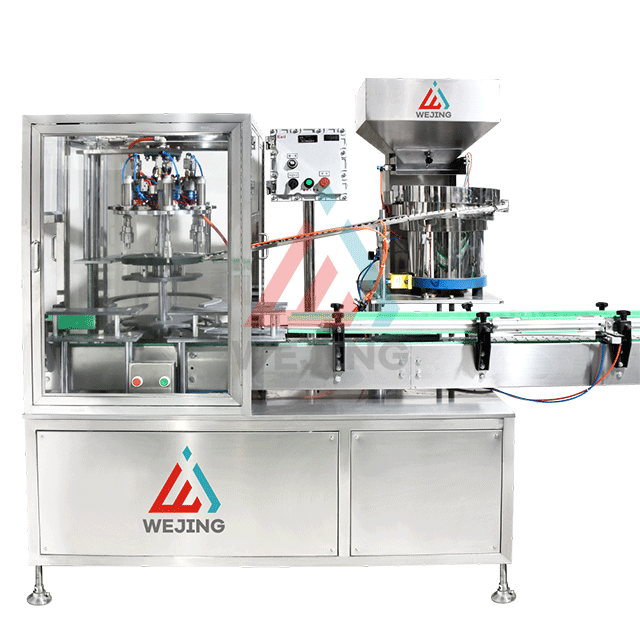

Liquid filling heads:

Understanding 'No Can No Fill' functionality: The machine intelligently halts when no cans are detected by the dual sensors positioned before the filling heads, meaning operations cease when cans are absent. This feature prevents wastage of raw materials and mitigates potential machinery malfunctions due to running without containers.

Weight checking machine:

Featuring automatic can input and output sensors, it efficiently manages can feeding, minimizing labor costs and enhancing overall efficiency by initiating and halting the process autonomously.

With real-time weight display, the machine presents intuitive and convenient parameter adjustments along with a straightforward calibration and adjustment function tailored to accommodate varying inspection speeds.

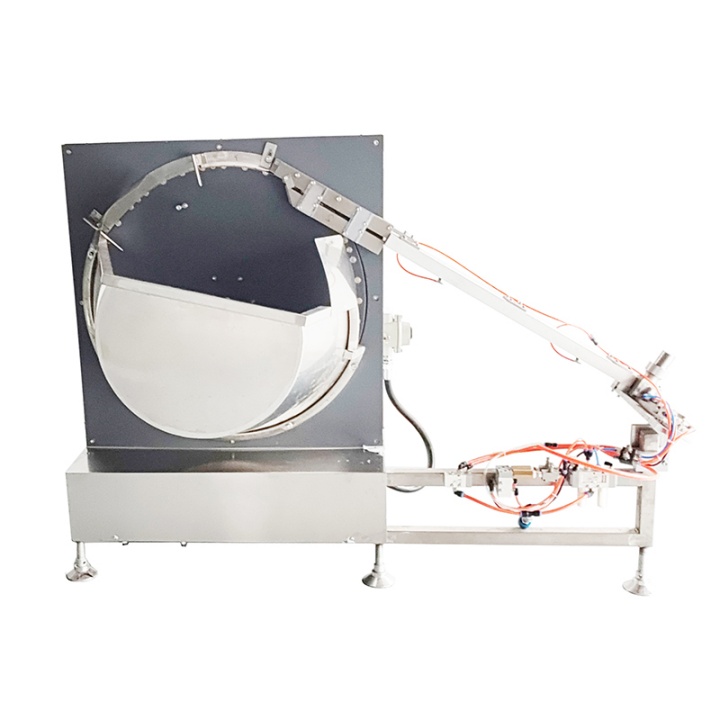

Auto valve inserting machine:

Equipped with a stop protection mechanism, the machine will halt its functioning in the absence of cans, when cans jam, or when actuators run out.

User-friendly adjustments can be made simply by raising the handle to alter the height. Additionally, adapting to different diameters requires a minimal switch of star wheel molds.

Auto cap presser machine:

The machine possesses a built-in cap alignment correction mechanism that minimizes cap wear, ensuring a fully automated process from cap delivery to final tightening with zero manual intervention. Transitioning between different can sizes is facilitated by an easy-to-replace transmission system.

Products:

1. Personal Care Sector: High-speed aerosol filling equipment plays a crucial role in crafting personal care items, including deodorants, hair styling sprays, body fragrances, shaving foams, and various aerosol cosmetic formulations, delivering effective and sanitary packaging methods.

2. Home and Cleaning Product Production: These machines prove invaluable in the assembly and containment of domestic cleaning supplies such as air purifiers, insect repellents, disinfecting aerosols, wood polishes, and oven cleaners, thereby ensuring high volume output and uniform product excellence.

3. Pharmaceutical and Medical Applications: Within the pharmaceutical domain, the deployment of high-speed aerosol filling processes is vital for the fabrication of metered-dose inhalers, topical treatments, and sanitizing sprays, requiring exact dose control and unwavering compliance with stringent industry regulations.

FAQ:

Q: Which product categories can an automatic aerosol filling machine process effectively?

A: It efficiently processes a broad array of aerosol products, extending from personal grooming articles, household sprays to medicinal formulations.

Q: Can an automatic aerosol filler adapt to any can dimension?

A: Indeed, majority of models are compatible with a diversity of can sizes, although some adjustments might be necessary.

Q: How does it maintain precise filling levels?

A: Through the employment of accurate valves, sensory devices, and programmable logic controller (PLC) controls to gauge and manage the product inflow.

Q: Is it safe to utilize automatic filling machines with inflammable substances?

A: Absolutely, provided they bear explosion-proof certification and incorporate the requisite safety mechanisms.

Q: Does it have the capability to identify and discard cans filled incorrectly?

A: Certain variants come equipped with weight-check mechanisms that detect and eliminate cans that don't meet the set standards.