Configuration:

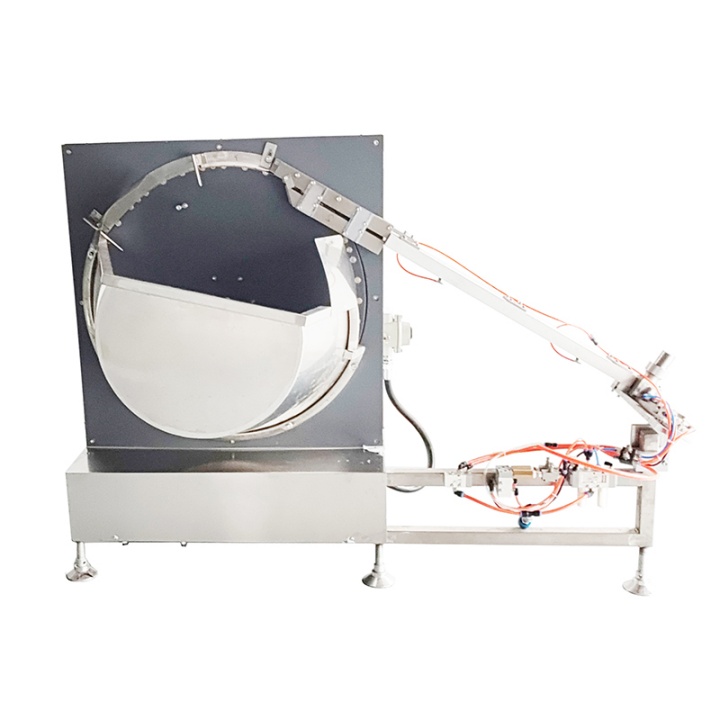

1. Container Loading Automation Process

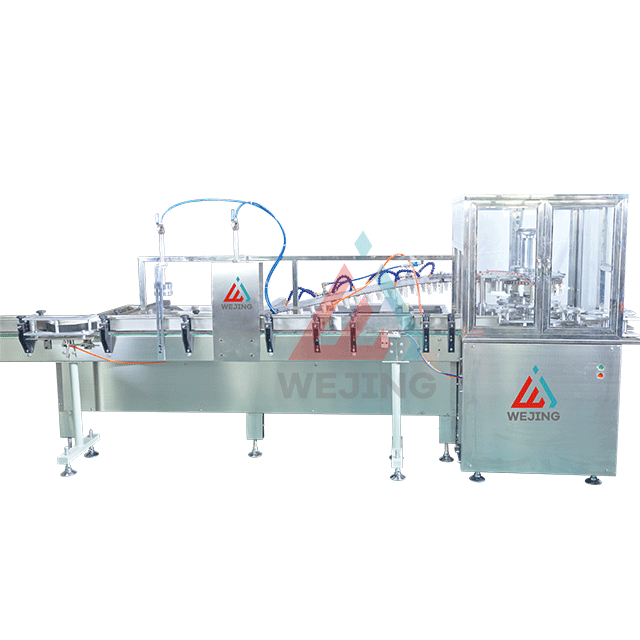

2. Fast Liquid Distribution Machinery

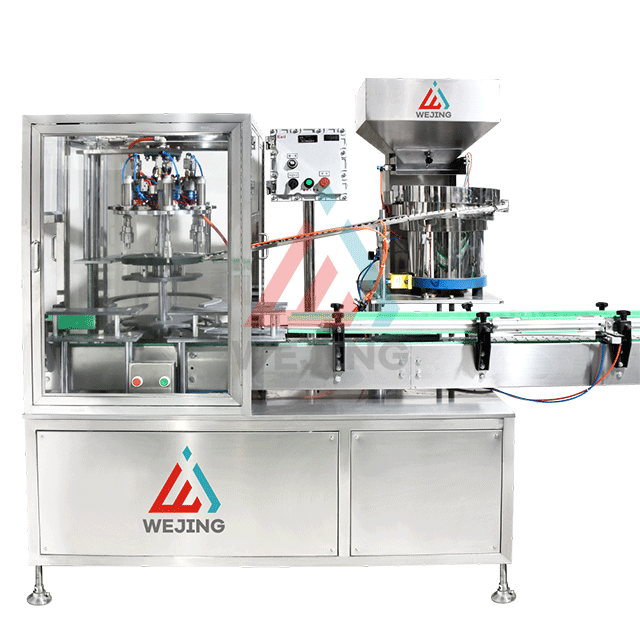

3. Automated Valve Incorporation Module

4. Swift Closure and Valve Alignment System

5. Comprehensive Propellant Injection Setup

6. Timely Mass Weighing Platform

7. Mechanized Actuator Mounting Unit

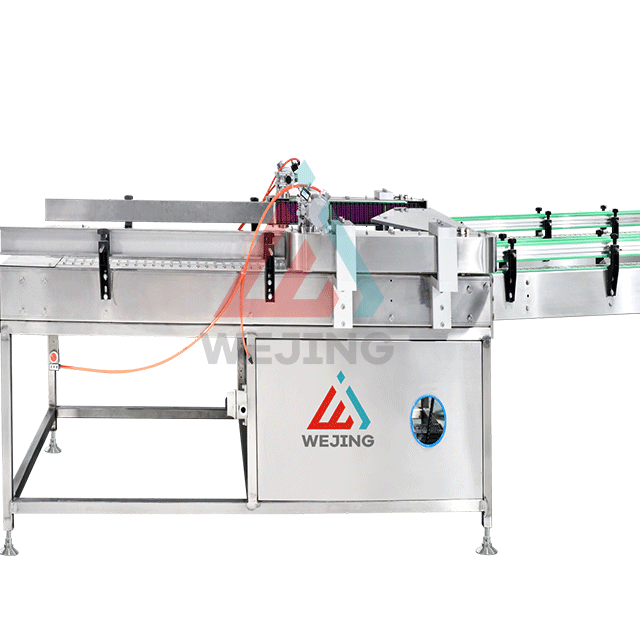

8. Quick Lid Application Equipment

9. Terminal Packaging Readiness Table

Technical Parameters:

Technical Parameter | Description |

Voltage | 380V/50HZ( can be customized ) |

Dimension(L*W*H) | 22000*4000*2000mm |

Production speed | 130-150 cans/min |

Propellant Type | The type of propellant used in the aerosol product (e.g., LPG, DME, N₂, CO₂, R134a, etc) |

Noise control | ≤80 dB |

Can Type | Tinplate can or aluminum can |

Driven Type | Pneumatic control |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

Filling accuracy | ≤±1% |

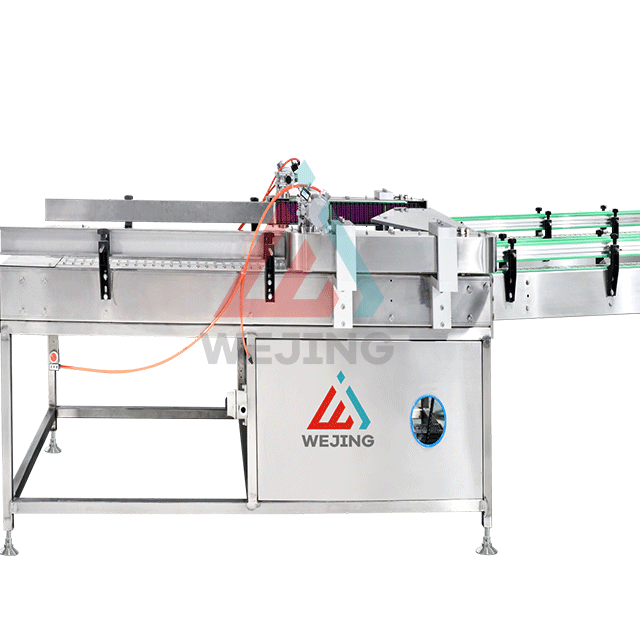

Detailed Images:

Can feeding Machine

Characteristics:

Ensures safety with fully pneumatic components.

Offers essential equipment alongside optional add-ons.

Ideal for clients engaged in large-scale aerosol product manufacturing.

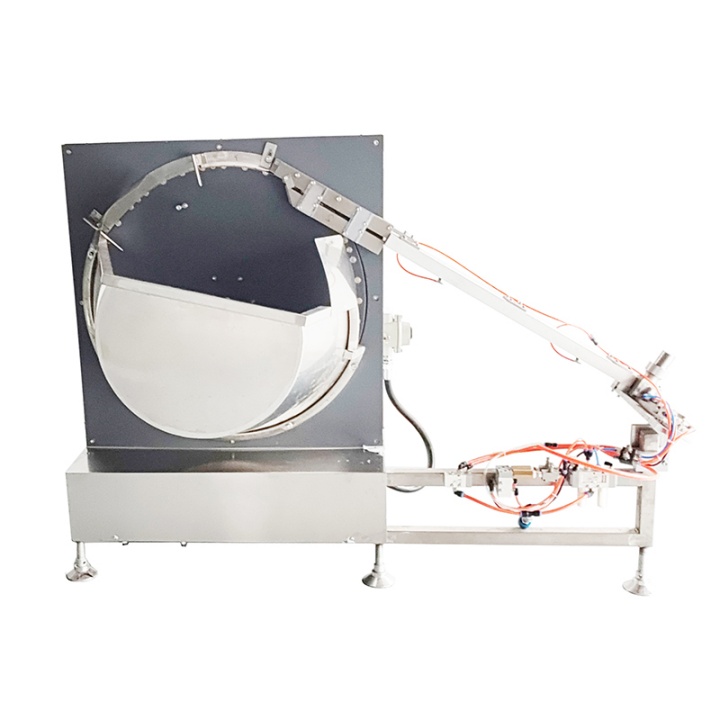

Weight checking machine

Key Features:

Ensures operational safety with fully pneumatic components.

Boasts user-friendly controls, outstanding stability, rapid response times, and superior accuracy.

Offers customizable checking speeds to adapt to diverse production scenarios.

Auto valve inserting machine

Key Features:

Guarantees secure operation through fully pneumatic power.

Offers intelligent sorting and actuator installation capabilities.

Demonstrates a high level of automation in its functions.

Auto cap presser machine

Key Features:

Ensures safe operation with fully pneumatic-driven components.

Accommodates a variety of cap sizes and shapes.

Offers an adjustable sealing speed to cater to diverse production requirements.

Products:

1. Personal Hygiene Market: High-speed aerosol filling technology serves as a pivotal element in the creation of personal care items - think deodorants, hair styling aerosols, body mists, shaving creams, and a myriad of aerosol cosmetics - offering efficient and hygienic packaging practices.

2. Domestic and Cleaning Goods Manufacturing: Such machines play an indispensable role in the assembly and packaging of household cleaning solutions, e.g., air fresheners, insecticides, disinfectant sprays, furniture polishes, and oven cleaners, contributing to high-output capacity and consistent product superiority.

3. Pharmaceutical and Healthcare Uses: In the realm of pharmaceuticals, the implementation of high-speed aerosol filling techniques is fundamental for the manufacture of metered-dose inhalers, topical medications, and sanitizing sprays, necessitating precise dosage management and unyielding adherence to rigorous regulatory guidelines.

FAQ:

Q: What types of aerosol products can an automatic filling machine process?

A: This type of machine can expertly handle a broad spectrum of aerosol products, ranging from everyday personal care essentials, household cleaning sprays, to specialized pharmaceutical formulas.

Q: Can an automatic aerosol filler adapt to cans of different dimensions?

A: Yes, indeed, most models are designed to accommodate various can sizes, although minor adjustments might sometimes be needed.

Q: How does the machine ensure precise filling measurements?

A: By leveraging precise valve technology, sensitive sensors, and advanced PLC control systems to meticulously measure and control the flow of the product.

Q: Are these machines safe to use for filling flammable substances?

A: Affirmative, provided they are certified explosion-proof and fortified with appropriate safety features to mitigate risks.

Q: Can the machine identify and reject cans that are either underfilled or overfilled?

A: Some models indeed come with integrated weight-inspection systems capable of identifying and discarding cans that fail to meet the specified fill requirements.