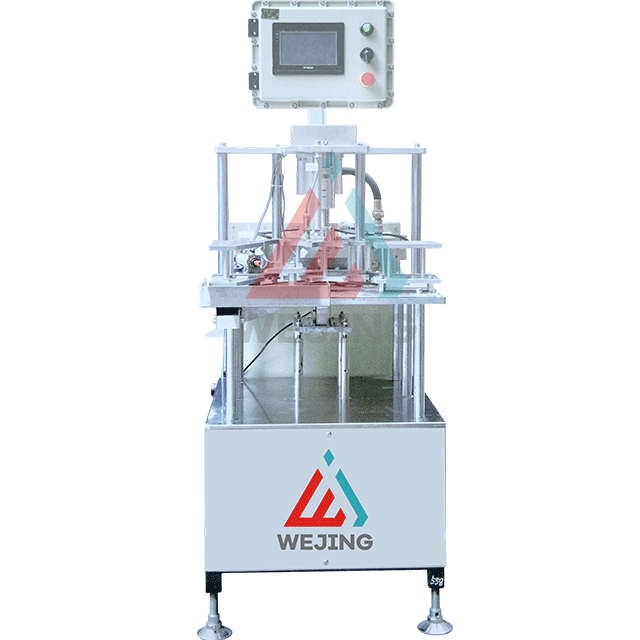

Main Features

1. The valve is automatically sent from the pipeline to the valve inserted device on the automaticproduction line by the selection plate, and then automatically put into the can mouth reqularly.

2. Pressed on the can mouth.

3. Increase crimping quality and prevent excessive volatilization of liquid.

4. Improve productivity and save labor.

Technical Parameters

Production speed: 60-70cans/minute

Power for selection plate: AC380V/50Hz/0.37KW

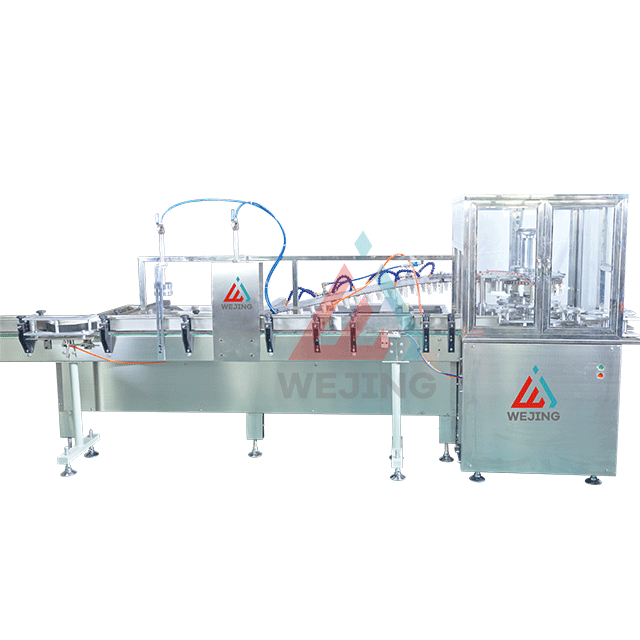

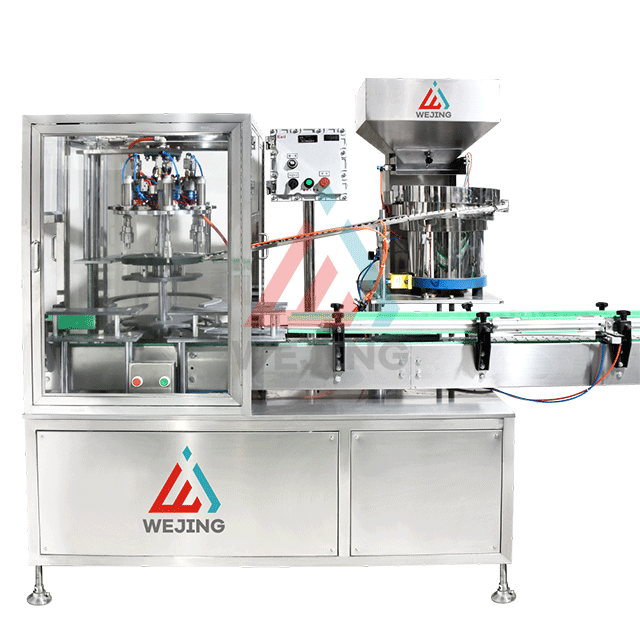

Detailed Images

Product Uses

Use the filter plate to select the correct direction, which is continuously transported by the pipelineand regularly placed in the can mouth, so as to replace the manpower and reduce the labor force.

1. Packaging industry: The Automatic Aluminum And Tin Valve Inserted Machine is widely used in the packaging industry to automatically insert aluminum and tin valves into packaging containers for food, beverages, cosmetics, and other products.

2. Pharmaceutical industry: In the pharmaceutical industry, this machine can be used to insert aluminum and tin valves into packaging containers for drugs, vaccines, and other products to ensure the freshness and quality of the products.

3. Chemical industry: The Automatic Aluminum And Tin Valve Inserted Machine is also suitable for the chemical industry to insert aluminum and tin valves into packaging containers for chemicals, adhesives, and other products.

4. Cosmetics industry: In the cosmetics industry, this machine can be used to insert aluminum and tin valves into packaging containers for cosmetics, perfumes, and other products to protect the quality and freshness of the products.

5. Food industry: The Automatic Aluminum And Tin Valve Inserted Machine is essential in the food industry. It can be used to insert aluminum and tin valves into packaging containers for food, beverages, and other products to extend shelf life and maintain product quality.

Product Operate Guide

1. Prepare the machine: Make sure the machine is properly installed and connected to the power source. Check if all components are in good condition.

2. Load the containers: Place the empty aerosol containers on the conveyor belt or in the designated loading area of the machine.

3. Adjust the settings: Set the appropriate parameters such as valve insertion depth, speed, and pressure according to the specific requirements of the aerosol filling process.

4. Start the machine: Press the start button or switch to activate the Automatic Aluminum And Tin Valve Inserted Machine. The machine will automatically insert the valves into the containers.

5. Monitor the process: Keep an eye on the machine's operation during the valve insertion process. Make sure there are no errors or malfunctions. If any issues arise, stop the machine immediately and rectify the problem.

FAQ

1. Can the machine handle different types of valves? The machine is designed to handle various types of valves commonly used in aerosol containers.

2. What is the production capacity of the machine? The production capacity of the machine varies depending on the model and configuration. It can range from several hundred to thousands of containers per hour.

3. Is the machine compatible with different types of aerosol filling lines? The machine is compatible with different types of aerosol filling lines and can be integrated into existing production processes.

4. How does the machine ensure the accuracy and consistency of valve insertion? The machine uses precision mechanisms and sensors to ensure accurate and consistent valve insertion. It can adjust the insertion depth and position according to the specific requirements of the containers.

5. What safety features are incorporated into the machine?

The machine incorporates various safety features, such as emergency stop buttons, protective covers, and sensors, to ensure the safety of operators and the integrity of the equipment.