1. Introduction

Are you looking to boost your production efficiency and ensure flawless labeling? With the right labeling machine, you can achieve both with ease. In this guide, we’ll dive into the different types of labeling machines, their key features, and how to choose the perfect one for your business. We’ll also introduce the Labeling Sticker Machine from Wejing, a top choice for industries like chemical, cosmetic, and pharmaceutical sectors.

If you're looking to streamline your labeling process, this guide will help you select the right labeling machine to boost efficiency and cut costs.

2. What is a Labeling Machine?

Definition and General Function of a Labeling Machine

A labeling machine is a type of automated machinery designed to apply labels to products, packaging, or containers in a precise and consistent manner. These machines are critical for industries that require large quantities of labeled products to be produced in a short period. The purpose of a labeling machine is not only to save time but also to ensure that every product is labeled correctly, which helps to avoid human errors and mislabeling that can lead to product recalls or confusion. Labeling machines come in various configurations depending on the product type and production requirements. Some machines apply labels to bottles, others to boxes, and some even to irregularly shaped products.

How Labeling Machines Streamline Production Lines

The primary advantage of using a labeling machine is the speed and efficiency it brings to the production process. When applied manually, labeling can be time-consuming and prone to mistakes, especially when there are variations in label sizes, shapes, or product shapes. A labeling machine, on the other hand, ensures consistent application of labels at high speeds, making the process faster and more reliable. For high-volume production lines, automated labeling machines can achieve speeds of hundreds or even thousands of labels per minute, which is impossible to match manually. This helps businesses meet high demand without compromising quality, all while reducing labor costs associated with manual labeling tasks.

Types of Products and Industries That Use Labeling Machines

Labeling machines serve a wide range of industries, from food and beverage manufacturing to pharmaceuticals, cosmetics, and even automotive parts production. In the food and beverage industry, labeling machines apply labels to bottles, cans, jars, and cartons with important product information such as nutritional facts, expiration dates, and branding. In the pharmaceutical sector, precise labeling is crucial for regulatory compliance, ensuring that every product is correctly labeled with important information such as ingredients, dosage instructions, and warnings. Cosmetic industries rely on labeling machines for packaging products like lotions, creams, and cosmetics, where label consistency is essential for brand identity and customer trust. Similarly, in manufacturing, labeling machines help identify products with barcodes or serial numbers, ensuring smooth inventory management and traceability.

Labeling machines are versatile and can handle different packaging materials like glass, plastic, metal, and cardboard, making them adaptable to a variety of products.

3. Types of Labeling Machines

Automatic Labeling Machines

Automatic labeling machines are designed for high-speed, high-volume applications. These machines fully automate the labeling process, meaning they require minimal human intervention. Products are automatically fed into the machine, and labels are applied as the products move through the production line. Automatic labeling machines are ideal for industries that have large-scale production needs, as they are built to handle continuous operation. These machines are capable of applying a variety of label types such as pressure-sensitive labels, shrink sleeves, and wrap-around labels, all at impressive speeds.

Industries That Typically Use Automatic Machines:

● Beverage and Bottling Industry: In high-speed bottling plants, automatic labeling machines ensure bottles are quickly and accurately labeled with product information and branding, such as expiration dates or barcodes.

● Pharmaceutical Industry: Where accuracy is critical for regulatory compliance, these machines help label medicine bottles, blister packs, and other pharmaceutical products with precise information required by law.

● Cosmetics and Personal Care: Automatic labeling machines are perfect for cosmetic products such as skincare, haircare, and makeup, where consistency is key to building brand identity.

Semi-Automatic Labeling Machines

Semi-automatic labeling machines require a level of operator involvement but are still more efficient than manual labeling. In these machines, operators load products into the system, but the machine takes care of the labeling process. This type of machine is ideal for businesses that produce products in medium volumes and need more flexibility than what an automatic machine offers. Semi-automatic machines can be adjusted to accommodate different product sizes and label types, making them a versatile solution for many businesses.

Key Features and Benefits:

● Flexibility in Product Sizes and Shapes: Semi-automatic labeling machines can often handle products of various shapes and sizes, providing a good balance between speed and versatility.

● Lower Upfront Cost: Compared to fully automatic machines, semi-automatic machines are more affordable, making them a good choice for small to medium-sized businesses.

● Easier Setup for Smaller Batches: Businesses with fluctuating production volumes or those that need to switch between different products regularly will benefit from the ease of setup offered by semi-automatic labeling machines.

Manual Labeling Machines

Manual labeling machines are the simplest and most affordable option. These machines require operators to manually apply the labels to products. While this option is significantly slower than automated machines, it may be the best choice for small-scale businesses or those producing custom or low-volume products. Manual labeling machines are easy to use and require minimal setup and maintenance, but they do come with the drawback of slower production speeds and potential human error in label application.

Pros and Cons of Manual Machines:

Manual labeling machines are affordable, easy to use, and ideal for small businesses with low-volume production needs. These machines are labor-intensive, slow, and can result in inconsistent labeling due to human error.

Specialized Labeling Machines

Specialized labeling machines are designed to cater to specific types of labeling needs. These machines are often customized to handle unique product shapes or sizes, such as bottles with irregular shapes or flat items that are difficult to label. Specialized machines are built to handle specific production challenges that standard labeling machines may not be able to accommodate.

Examples of Specialized Machines:

● Bottle Labelers: Ideal for labeling round, cylindrical products such as bottles, jars, and cans.

● Wrap-Around Labelers: These machines apply labels around cylindrical products, ensuring precise and seamless labeling on containers.

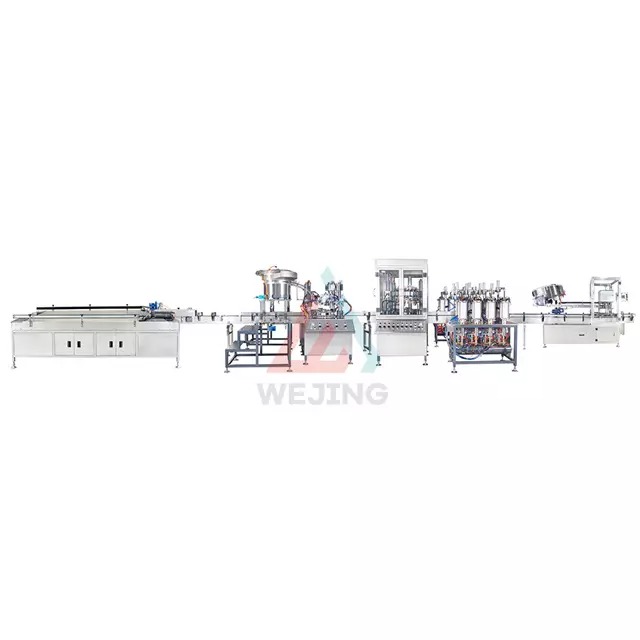

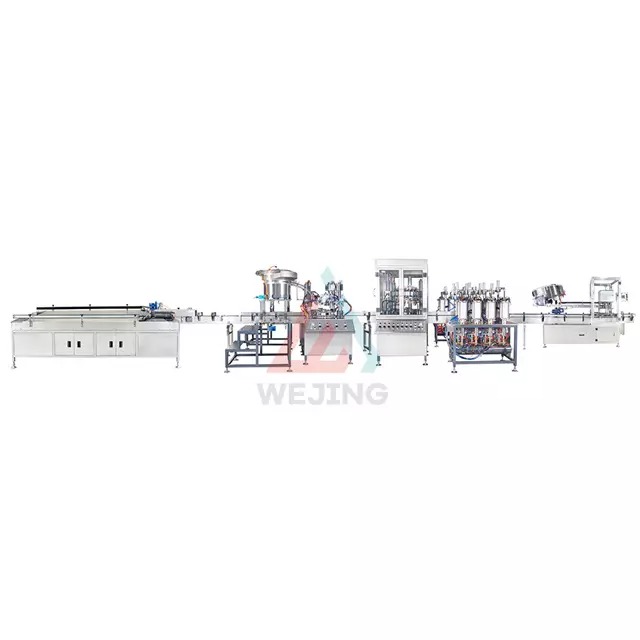

For industries such as chemical, cosmetic, and pharmaceutical, the Wejing Labeling Sticker Machine is the ultimate solution for improving labeling efficiency. Specifically designed for aerosol filling lines, this machine ensures precise label placement, fast labeling speeds, and high-performance consistency. The Wejing Labeling Sticker Machine is easy to operate, making it ideal for production lines that require rapid turnaround and high-quality labeling. Whether you're working with small batches or high-volume production, this machine offers unmatched performance, allowing businesses to meet their labeling needs without compromising on speed or accuracy. The user-friendly design and top-quality construction of the Wejing Labeling Sticker Machine ensure that it delivers optimal performance, improving both production efficiency and product quality.

If you're in the chemical, cosmetic, or pharmaceutical industry and need precise labeling for products like aerosols or bottles, the Wejing Labeling Sticker Machine is a great option to enhance productivity and maintain labeling accuracy.

4. Key Features to Look for in a Labeling Machine

Speed and Efficiency

When selecting a labeling machine, one of the first factors to consider is the speed and efficiency of the machine. Speed refers to the number of products the machine can label in a given time, usually measured in products per minute (ppm). Efficiency, on the other hand, is about how quickly and accurately the machine can label products without slowing down or making mistakes. A high-speed labeling machine is particularly important for businesses that have high production volumes and need to meet tight deadlines.

However, it’s essential to balance speed with accuracy. Faster machines can achieve higher throughput, but if they sacrifice precision, it could lead to labeling errors that may result in wasted materials and even product recalls. Therefore, when selecting a labeling machine, it’s crucial to look for one that strikes the right balance between speed and accuracy.

Key Metrics to Consider:

● Labeling Speed: Measured in products per minute (ppm). The higher the ppm, the faster the labeling process.

● Downtime: Refers to the amount of time the machine is not in operation due to maintenance or breakdowns. Minimizing downtime is crucial for maintaining production efficiency.

● Throughput Capacity: This refers to the maximum volume of products the machine can handle in a given period. The higher the throughput capacity, the more products the machine can label, which is essential for businesses with high-volume production lines.

Label Application Precision

Labeling precision is critical because poorly applied labels can affect product appearance and lead to regulatory issues. Accurate label placement ensures that products are properly branded and that all relevant information is displayed in the right spot. Many modern labeling machines come with advanced sensors and automated calibration features to guarantee precise label application.

Features Ensuring Precision:

● Sensors: These are used to detect the position of the product and ensure that the label is applied in the correct location.

● Adjustable Speed: The ability to adjust labeling speed based on the product type ensures that the machine operates efficiently while maintaining high accuracy.

Ease of Use and Maintenance

User-friendly controls and simple maintenance are essential when choosing a labeling machine. Machines with intuitive interfaces and easy-to-understand controls allow operators to quickly set up and operate them, reducing the risk of errors and improving overall productivity. Additionally, machines that are easy to maintain and clean help minimize downtime and ensure that the machine continues to operate efficiently over time.

How This Impacts Overall Machine Uptime:

● Quick Changeover: Machines with parts that are easy to replace or adjust can be set up for different products more quickly, reducing production delays.

● Low Maintenance Requirements: Machines that require less maintenance and have easy-to-access parts will keep your production line running smoothly without frequent service interruptions.

Versatility and Adaptability

Versatility is another important factor when selecting a labeling machine. A versatile machine can handle a wide range of products and label types, making it a great investment for businesses that produce various items. Look for machines that can easily be adjusted to accommodate different label sizes, shapes, and materials. This will provide your business with greater flexibility as product lines and packaging requirements change.

Machines that can adjust to different types of labels and products ensure flexibility, allowing businesses to scale up production as needed.

5. Benefits of Using a Labeling Machine

Increased Productivity

Labeling machines significantly improve productivity by automating the labeling process, which saves time and reduces the need for manual labor. Automation means that machines can apply labels much faster than human workers, which is essential for businesses with high-volume production lines. The increased speed also allows businesses to meet tight deadlines and increase their output without sacrificing quality.

Comparison Between Manual and Automated Labeling:

● Manual: Slower, labor-intensive, prone to errors.

● Automated: Faster, more accurate, and consistent.

Cost-Effectiveness

The initial investment in a labeling machine can be high, but over time, the machine pays for itself through cost savings. Automated machines reduce the need for manual labor, which translates to lower labor costs. Furthermore, automated machines minimize errors, which reduces waste and the need for rework. For businesses that produce large volumes of products, the return on investment (ROI) for an automated labeling machine is often realized relatively quickly.

Lower Labor Costs and Reduced Errors:

● Labor Savings: With fewer employees needed to handle labeling, businesses can save on wages and training costs.

● Error Reduction: Automated systems reduce the risk of mislabeling, ensuring products are labeled accurately and consistently.

Improved Label Quality

Consistency in label application is crucial for maintaining product quality and brand reputation. Automated labeling machines ensure that each product receives the same precise label placement, improving the overall aesthetic of the product. Consistency in labeling also enhances the perceived quality of your products, which can lead to higher consumer trust and satisfaction.

Enhanced Brand Image:

● Consistent labeling improves brand recognition and consumer loyalty.

● Better-quality labels result in a more professional product presentation.

When choosing a labeling machine, assess how it can improve your brand’s image through precise and consistent labeling.

6. Conclusion

Labeling machines are invaluable tools for businesses looking to improve production efficiency, reduce labor costs, and ensure consistent, high-quality labeling. By understanding the different types of machines and their features, businesses can make informed decisions that align with their needs. Remember to choose a machine that can scale with your production demands and provide a high return on investment. Investing in the right labeling technology will boost your brand’s professionalism and improve operational efficiency. For industries such as chemical, cosmetic, and pharmaceutical, Wejing's Labeling Sticker Machine offers unmatched precision and speed, making it an ideal solution for improving your labeling process. Contact Wejing today to learn more and elevate your production line with our state-of-the-art labeling machines. Don't miss out on the opportunity to enhance your efficiency and quality—ask about our Wejing Labeling Sticker Machine now!

FAQ

Q: What is a Labeling Machine?

A: A labeling machine is an automated system designed to apply labels to products, containers, or packaging in a precise and efficient manner. It helps businesses streamline their production processes by ensuring consistent labeling at high speeds.

Q: How does a Labeling Machine work?

A: A labeling machine works by feeding products through a conveyor belt where labels are automatically applied. The machine uses sensors to ensure accurate placement and can handle different types of labels, including adhesive, shrink, or wrap-around labels.

Q: Why should I invest in a Labeling Machine?

A: Investing in a labeling machine improves production efficiency, reduces labor costs, and ensures consistent, high-quality labeling. It helps businesses meet high production demands while maintaining accuracy and speed.

Q: What industries use Labeling Machines?

A: Labeling machines are used in various industries, including food and beverage, pharmaceuticals, cosmetics, and manufacturing. They are essential for applying regulatory, branding, and product information on packaging.