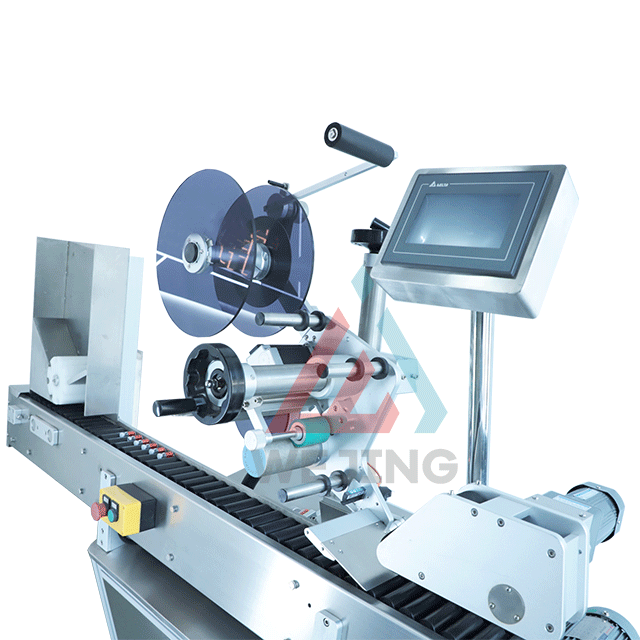

Operational features:

1. Automatic labeling: It can apply labels to ampoules automatically at high speeds.

2. Precise positioning: It ensures accurate label positioning for consistent labeling quality.

3. Adjustable parameters: It allows easy operation and adjustment of labeling parameters.

4. Safety features: It incorporates safety mechanisms to safeguard the operator.

5. Versatile applications: It can handle various label sizes, shapes, and materials.

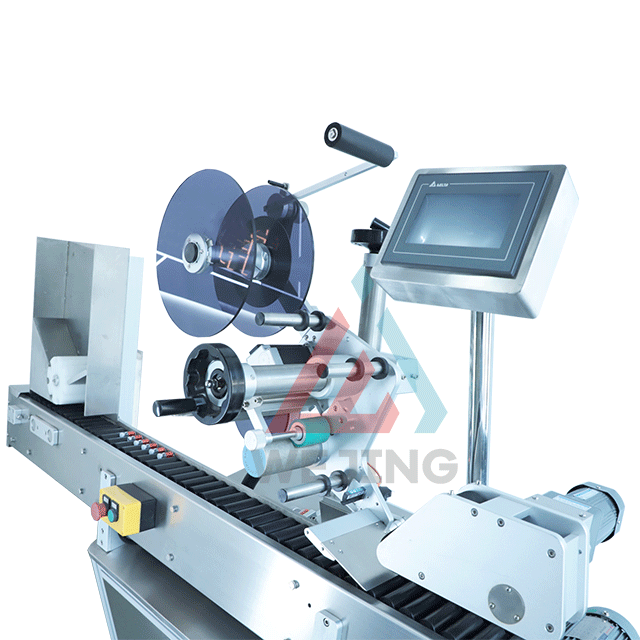

Technical Parameters:

Labeling speed | 0-100P/min (depending on product and label size) |

Labeling accuracy | ± 1mm (excluding errors such as product labels) |

Applicable product size | Diameter 15-35mm; Height 30-100mm; |

Applicable label range | Length 10-100mm, base paper width 10-100mm |

Maximum label supply | Within an outer diameter of 300 and an inner diameter of 76mm |

Environmental temperature/humidity | 0-50℃/15-85% |

Voltage | AC220V/50HZ |

Dimension | 2200*1000*1700mm(L*W*H) |

Weight | 190kg |

Product application:

1. Pharmaceutical industry: It is used for labeling ampoules in pharmaceutical production lines.

2. Cosmetic industry: It applies labels to ampoules in cosmetic packaging processes.

3. Chemical industry: It is employed for labeling small bottles in chemical laboratories and production facilities.

4. Medical device industry: It labels ampoules and vials in medical device manufacturing.

5. Laboratory research: It is utilized for labeling samples and containers in laboratories.

Product operation:

1. Prepare ampoules and labels: Ensure ampoules are clean and labels are properly aligned.

2. Load ampoules: Place the ampoules into the designated feeding area of the labeling machine.

3. Adjust labeling settings: Set the appropriate labeling parameters such as label position and speed.

4. Start the labeling process: Activate the labeling machine to begin applying labels to the ampoules.

5. Monitor the labeling: Inspect the labeled ampoules to ensure accurate and consistent labeling.

Maintenance methods:

1. Regular cleaning: Remove dirt and debris from the labeling machine to keep it in good condition.

2. Lubrication: Apply appropriate amount lubricant to moving parts to ensure smooth operation.

3. Inspection of belts and rollers: Check for wear or damage and replace if necessary.

4. Calibration: Verify the accuracy of label positioning and adjust as needed.

5. Electrical system check: Inspect electrical connections and components for proper functioning.