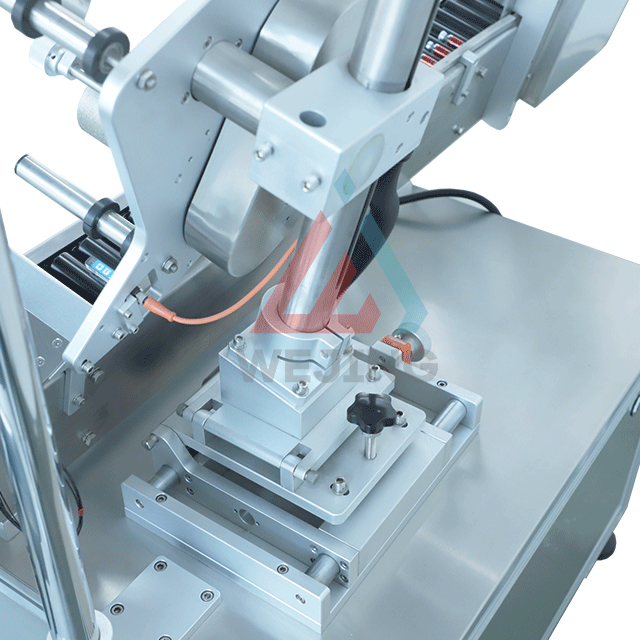

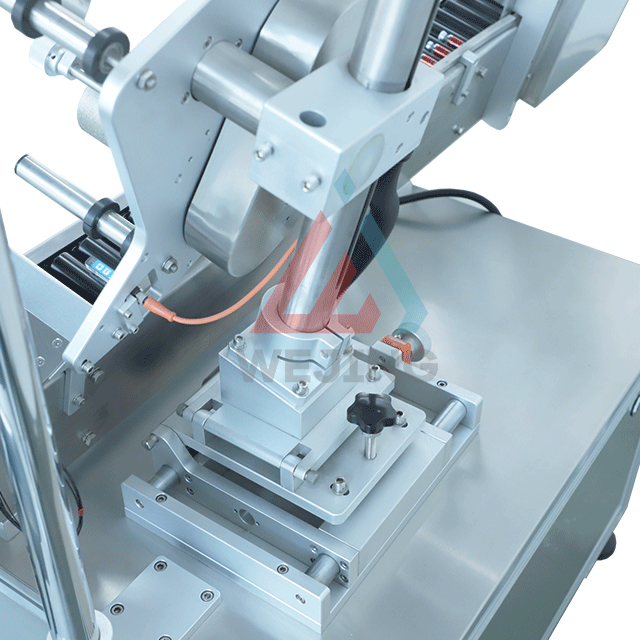

Structural features:

1. Unwinding wheel: used to place roll labels.

2. Buffer wheel: When the device is started, it can absorb the tension of the drum material, keep the material in contact with each roll, and prevent material fracture.

3. Guiding roller: It plays a guiding and positioning role in the material of the drum.

4. Drive roller: Drive the drum material to achieve normal labeling.

5. Reeling wheel: The bottom paper after rewinding and labeling is synchronously driven and adjusted by a friction device.

6. Stripping board: When the bottom paper changes direction through the peeling board, the label is easy to label and detach from the bottom paper, achieving contact with the labeled object.

7. Labeling roller: Apply the label that is detached from the backing paper evenly and smoothly onto the object to be pasted.

Technical Parameters:

Labeling speed | 0-100P/min (depending on product and label size) |

Labeling accuracy | ± 1mm (excluding errors such as product labels) |

Applicable product size | Diameter 15-35mm; Height 30-100mm; |

Applicable label range | Length 10-100mm, base paper width 10-100mm |

Maximum label supply | Within an outer diameter of 300 and an inner diameter of 76mm |

Environmental temperature/humidity | 0-50℃/15-85% |

Voltage | AC220V/50HZ |

Dimension | 2200*1000*1700mm(L*W*H) |

Weight | 190kg |

Product application:

1. High labeling accuracy: It ensures precise labeling on the ampoules.

2. High labeling speed: It enables efficient production processes.

3. User-friendly design: With a simple interface and easy operation.

4. Flexibility: It can handle various sizes and shapes of ampoules.

5. Durability: It ensures reliable performance over time.

Product operation:

1. Label feeding: The labeling machine automatically feeds the labels from the label roll.

2. Ampoule positioning: The ampoules are precisely positioned for labeling.

3. Label application: The labeling head applies the labels to the ampoules.

4. Inspection: The machine checks the labeled ampoules for accuracy.

5. Output: The labeled ampoules are discharged from the machine.

Maintenance methods:

1. Regular cleaning: Clean the machine regularly to remove dirt and debris that may accumulate on the machine.

2. Check the labels: Check the labels to ensure they are properly aligned and applied to the ampoules.

3. Check the conveyor belt: Check the conveyor belt to ensure it is properly aligned and functioning properly.

4. Lubricate moving parts: Lubricate moving parts regularly to ensure smooth operation.

5. Check the electrical components: Check the electrical components to ensure they are functioning properly and there are no loose connections.