Product Advantage:

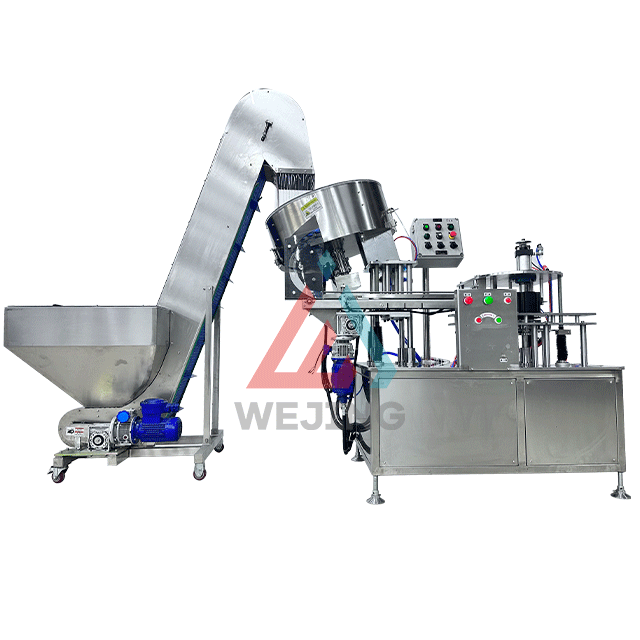

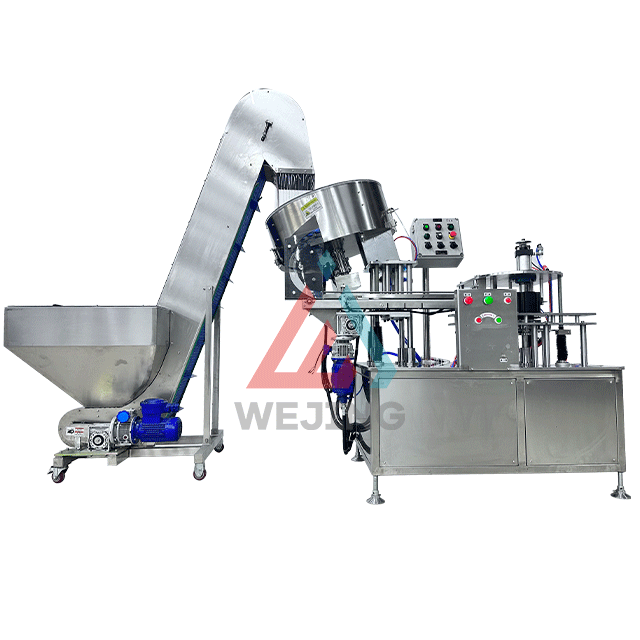

1. This machine has a vibration sorting machine for aerosol caps and automatically supplies aerosol caps to the pressing machine. The pressure can be fine tuned to ensure that the lid is completely fixed, but it will not accidentally spray out.

2. This machine can significantly improve the level of automation, improve work efficiency, and save labor costs. For many people, the automatic aerosol capping machine on the aerosol production line is an important component of their daily beauty. Our aerosol production line's fully automatic aerosol capping machine is produced according to strict management regulations, with reliable quality.

3. Before launch, it had already passed tests based on international rules and obtained certification from multiple authoritative institutions. For clients seeking business opportunities, Wejing is worth investing in. Our capable employees have always been committed to improving and upgrading technology. This product is widely used in filling machines.

Technical Parameters:

Technical Parameter | Description |

Speed | ≥ 120 bottles /min |

Suitable can diameter | 35-70mm |

Suitable can height | 70-330mm |

Control | Electricity control |

Alarm system | Equipped with uncovered alarm device |

Air source | 0.8Mpa |

Power | 2kW |

Size | 1900*1700*850mm |

Weight | 300kg |

Product Uses:

1. Personal care and hygiene: This production line is capable of packaging various personal care products, including hairspray, deodorant, and sunscreen spray.

2. Home improvement and cleaning: The production line can be utilized for packaging household products such as air fresheners, furniture polish sprays, and carpet cleaners.

3. Automotive and industrial: This line is well-suited for packaging automotive and industrial products like lubricants, paints, and adhesives.

4. Gardening and agriculture: The production line can also be employed in packaging garden and agricultural products such as plant fertilizers, pesticides, and herbicides.

5. Medical and pharmaceutical: The production line is suitable for packaging medical and pharmaceutical products, including nasal sprays, asthma inhalers, and disinfectant sprays.

Product Operate Guide:

1. Startup inspection: Before turning on the device, make sure all components are installed and connected correctly. Verify that the power supply, air source, and conveyor belt are functioning properly.

2. Adjustment of parameters: Based on the requirements of different products, adjust the equipment parameters such as pressure, speed, and temperature to ensure the best capping effect.

3. Feeding and conveying: Place the aerosol cans waiting for capping on the conveyor belt, and ensure an appropriate spacing between the cans to avoid congestion or missed caps.

4. Activation of the equipment: After confirming that all preparations are complete, start the equipment. Observe the operation of the equipment to ensure a smooth capping process.

5. Inspection of quality: Regularly check the quality of the caps, such as sealability and appearance. If any problems are identified, adjust the equipment parameters or perform maintenance in a timely manner.

It is important to note that this is only a basic operating guide, and the specific operating steps and precautions may vary depending on the equipment model and production requirements. Before operating the equipment, please carefully read the operating manual and follow the instructions of professionals.

FAQ:

1. What is the High Speed Autmatic Aerosol Cap Placing Machine?

The High Speed Autmatic Aerosol Cap Placing Machine is a fully automated equipment designed for high-speed and accurate placement of caps onto aerosol cans.

2. What are the main features of this machine? This machine features high placement speed, accurate cap alignment, and reliable performance. It can handle a variety of cap sizes and shapes, and is suitable for use in the production of aerosol cans in various industries.

3. How does the High Speed Autmatic Aerosol Cap Placing Machine work? The machine uses a pneumatic or mechanical feeding system to convey caps to the cap placement station. Then, using a servo motor or cam mechanism, the caps are precisely aligned and placed onto the aerosol cans.

4. What are the benefits of using this machine? Using this machine can improve production efficiency, reduce labor costs, and ensure consistent cap placement quality. It can also help to prevent cap leakage and other quality problems.

5. How is quality control ensured during the production process?

Quality control is ensured through various inspection stations incorporated into the production line. These stations include visual inspection for any defects, leak testing to ensure proper seals, and cap alignment verification. By implementing these quality control measures, defects can be minimized, and the integrity and safety of the aerosol spray cans are ensured.