2024.6.6 update

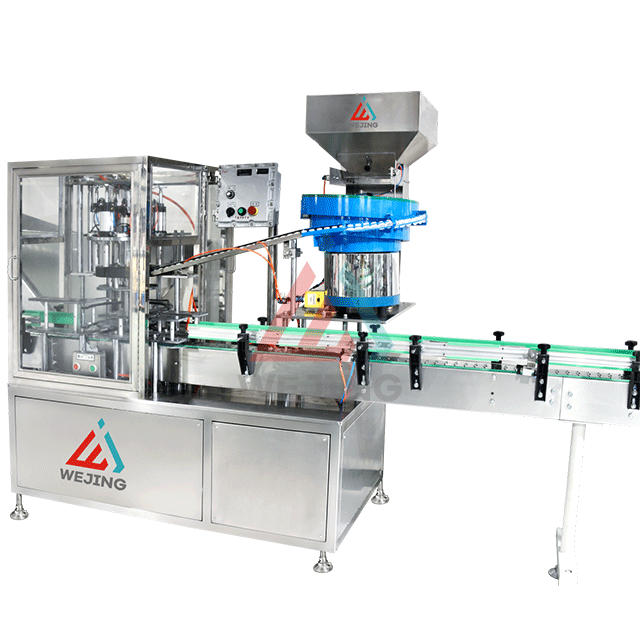

Configuration:

1. Auto Can feeding Machine

2. Electronic Weight CheckingMachine

3. Auto Actuator Fixed Machine

4. Safety cover Fixed Machine

5. Plastic Cap Inserted and Fixed Machine

6. Valve Inserted Machine

7. Water bath Detecting Machine

8. Actuator Fixed Machine

9. Glass Bead Inserted lachine

Technical Parameters:

Technical Parameter | Description |

Voltage | 380V/50HZ( can be customized ) |

Dimension(L*W*H) | 22000*4000*2000mm |

Production speed | 130-150 cans/min |

Propellant Type | The type of propellant used in the aerosol product (e.g., LPG, DME, N₂, CO₂, R134a, etc) |

Noise control | ≤80 dB |

Can Type | Tinplate can or aluminum can |

Driven Type | Pneumatic control |

Material | SS304 ( some parts can be SS316) |

Warranty | 1 year |

Key Selling Points | High speed fully automatic high production |

Maintenance Requirements | Recommended maintenance procedures and schedules |

Certifications and Standards | CE&ISO9001 |

Filling accuracy | ≤±1% |

Detailed Images:

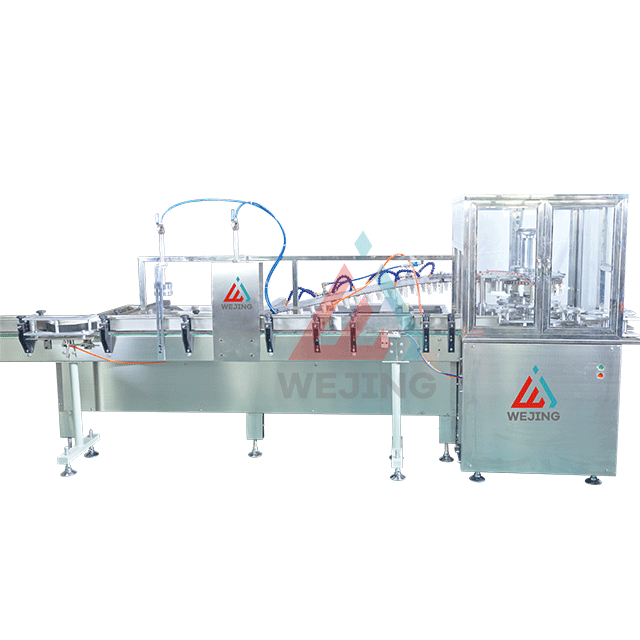

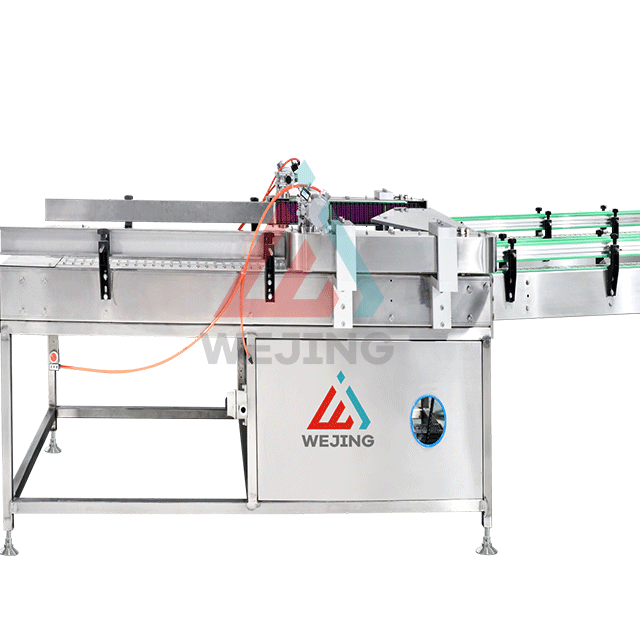

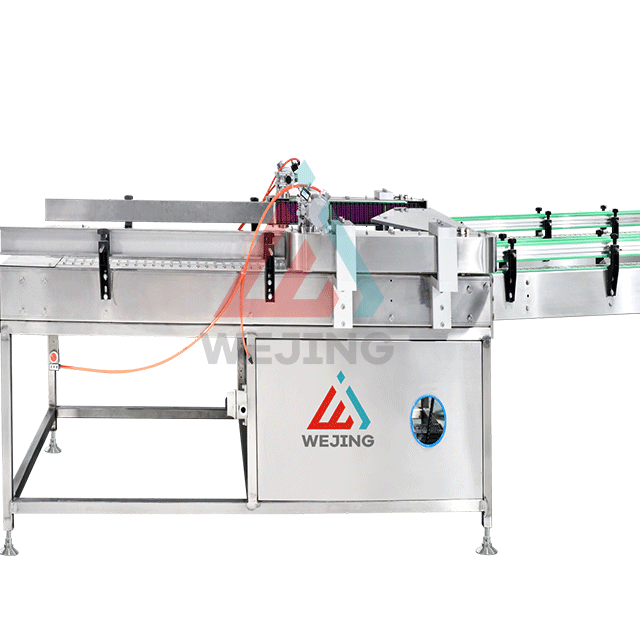

Can feeding Machine

Keepthe cans feeding properly andorderly on the conveyor belt.

Weight checking machine

used for online weight inspection of each can in aerosol production line.

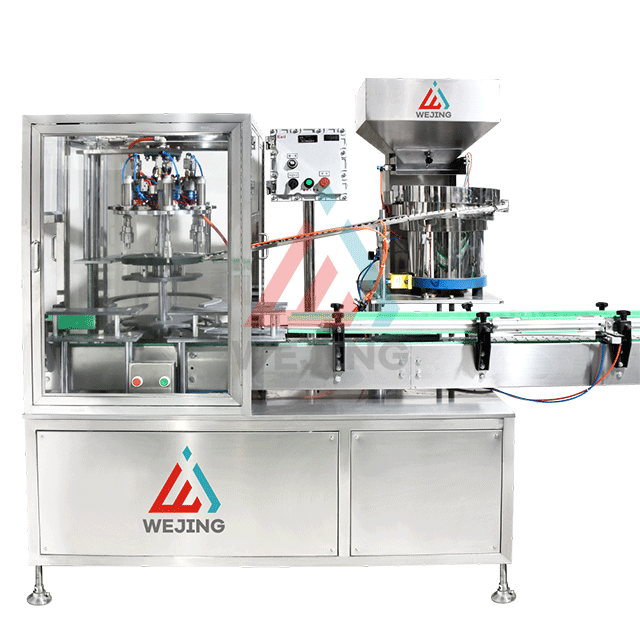

Auto Actuator Fixed Machine

used for the installation of spraactuators of aerosol products

Safety cover Fixed Machine

used for the installation of spray safety cover of aerosol

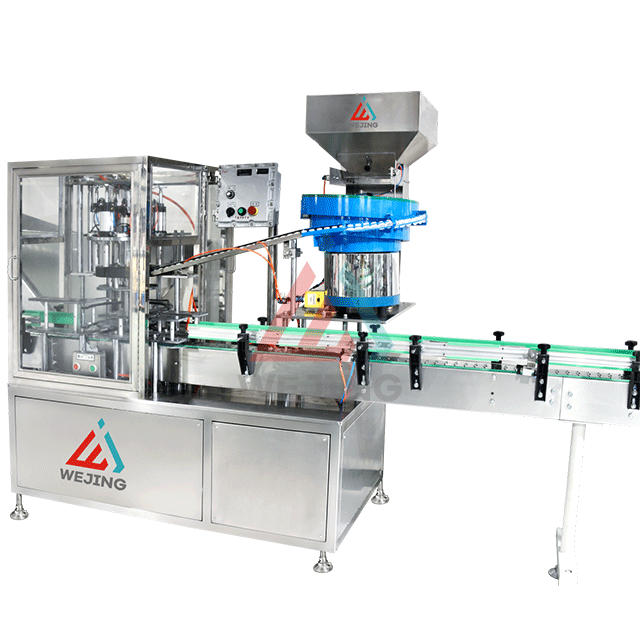

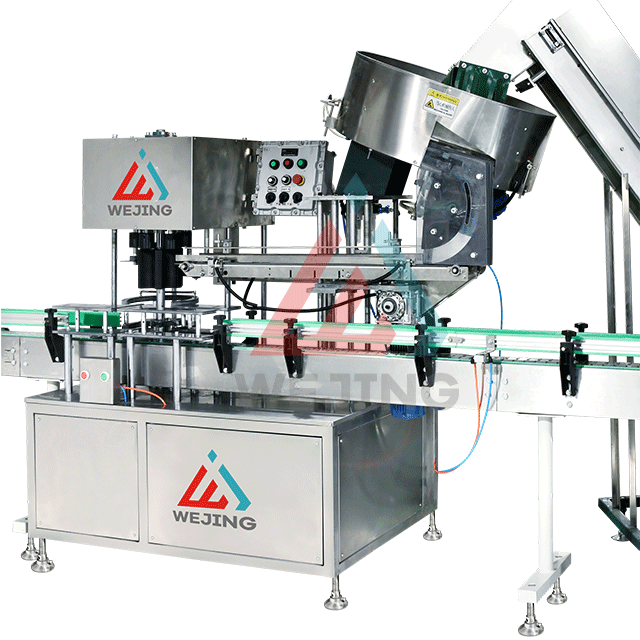

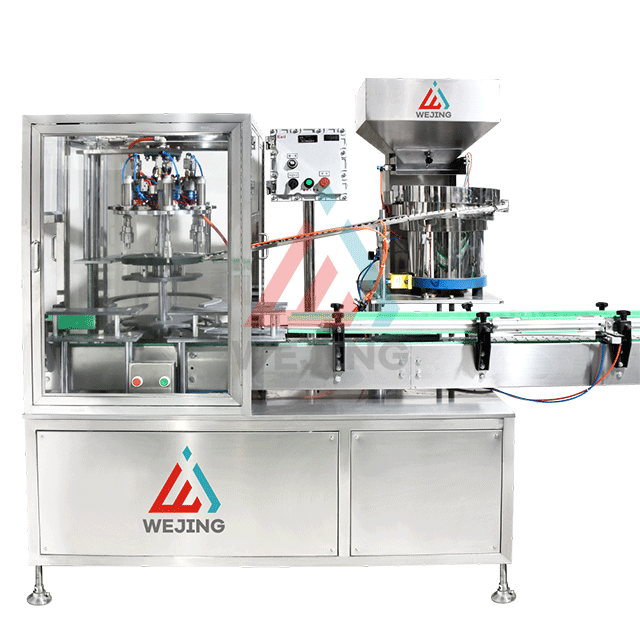

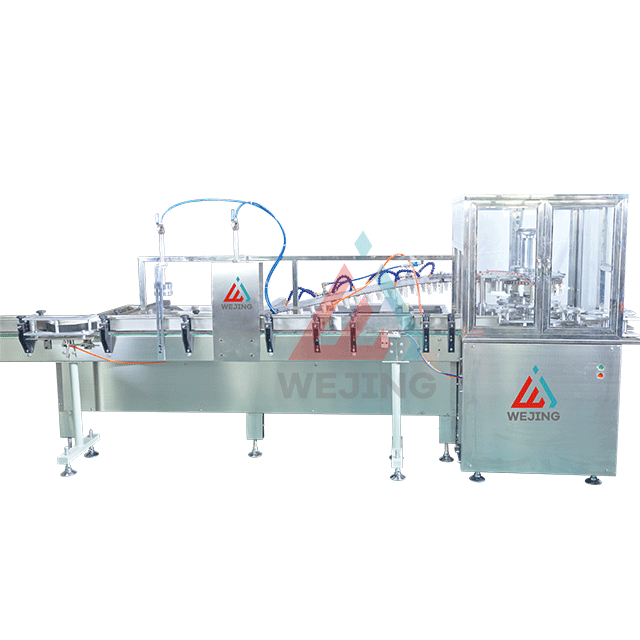

Auto valve inserting machine

is composed of valve selecting mechanism,valve inserting mechanism and pressing valve mechanism.

Auto cap presser machine

used for the outer plastic cap packaging of aerosol products.

Water bath Detecting Machine

The aerosol products are automatically clamped and brought into the detection groove through the host for continuous water bath detection.

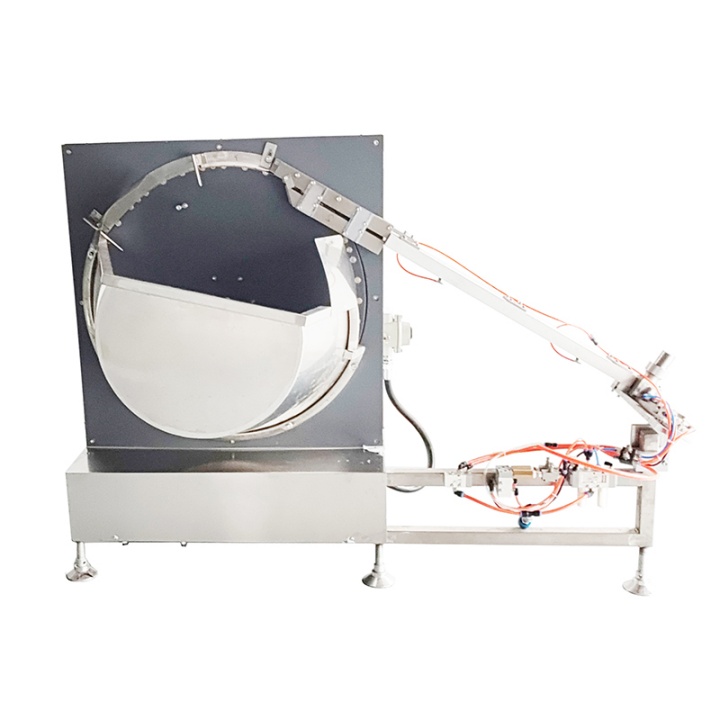

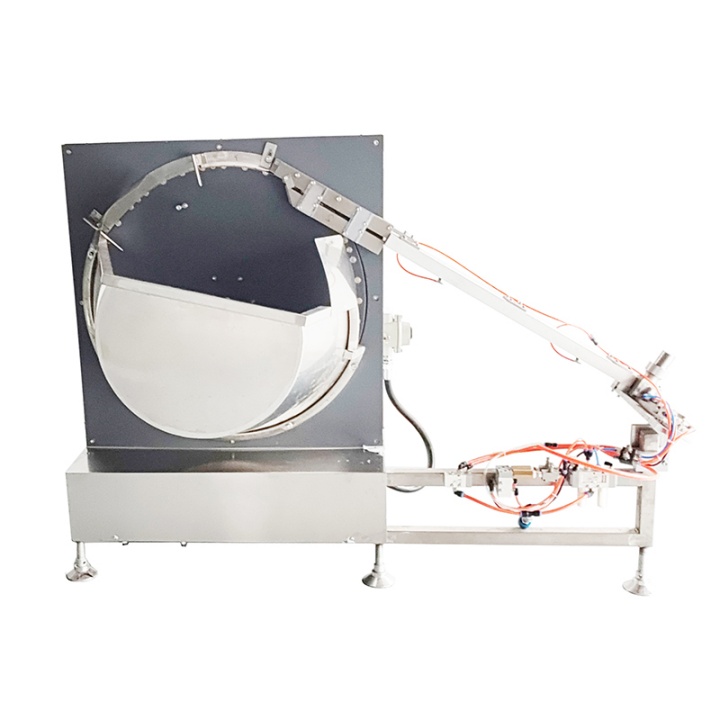

G lass Bead Inserted lachine

lass Bead Inserted lachine

It is composed of a funnel,a rotary table self selecting glass bead device,widely used in automatic spray painting,happy ribbon,cosmetics and other glass bead industries.

Products:

1. Personal Care: Processes deodorants, hair sprays, and cosmetics, ensuring quick, hygienic packaging.

2. Household Cleaning: Fills air fresheners, disinfectants, and polishes with high output consistency.

3. Pharmaceuticals: For MDIs, topical sprays, and sanitizers needing accurate doses and cleanliness.

4. Industrial Use: Packages lubricants, adhesives, and coatings with precision and speed.

FAQ:

Q: What types of products can a high speed aerosol filling machine package?

A: It packages various aerosol products like deodorants, paints, and personal care items.

Q: Does the machine accommodate different aerosol can sizes?

A: Affirmative, it's adaptable to multiple can diameters and heights through changeable components.

Q: How accurate is the filling process in these machines?

A: Precision valves and automated systems maintain accuracy, often supported by weigh scales for verification.

Q: Are these machines suitable for filling flammable substances?

A: They are if they meet ATEX or similar safety certifications for hazardous environments.

Q: Does the machine have safeguards against overfilling or underfilling?

A: Many models come equipped with weight check systems that automatically reject improperly filled cans.