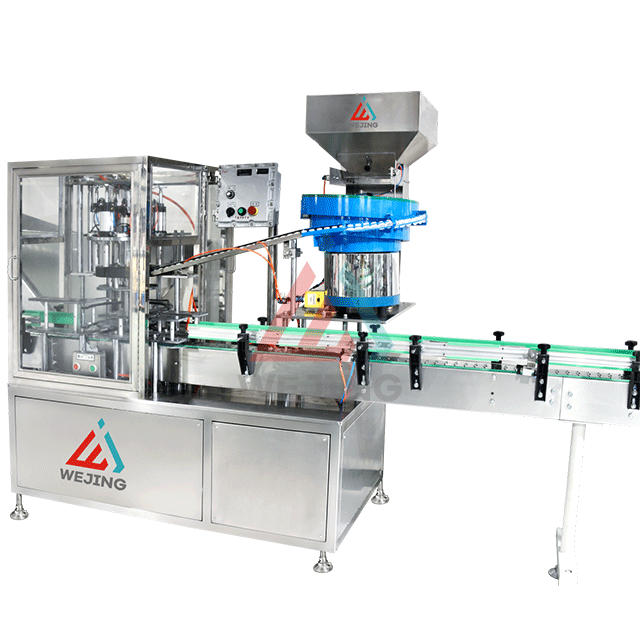

Configuration:

1. Automated Can Loading System

2. Digital Weight Verification Equipment

3. Automatic Actuator Mounting Unit

4. Protective Cover Attachment Device

5. Plastic Cap Placement and Securing Machinery

6. Valve Insertion Station

7. Immersion Testing Unit (Water Bath)

8. Mechanized Actuator Attachment Tool

9. Glass Bead Inserter Machine

Technical Parameters:

Production speed | 130-150 bottles/min |

Filling volume | 10-1200ml |

Repeated filling accuracy | ±1% |

Can size | 1inch aerosol can, diameter:φ40-φ70 height: 85-300mm |

Pressure of air compressed | 0.7-0.85Mpa |

Air consumption | 5m³/min |

Power supply | AC380V/50Hz/11KW |

Detailed Images:

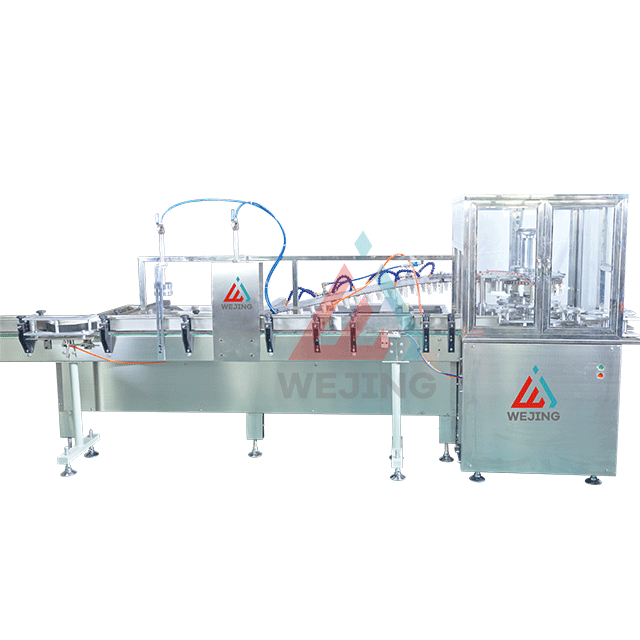

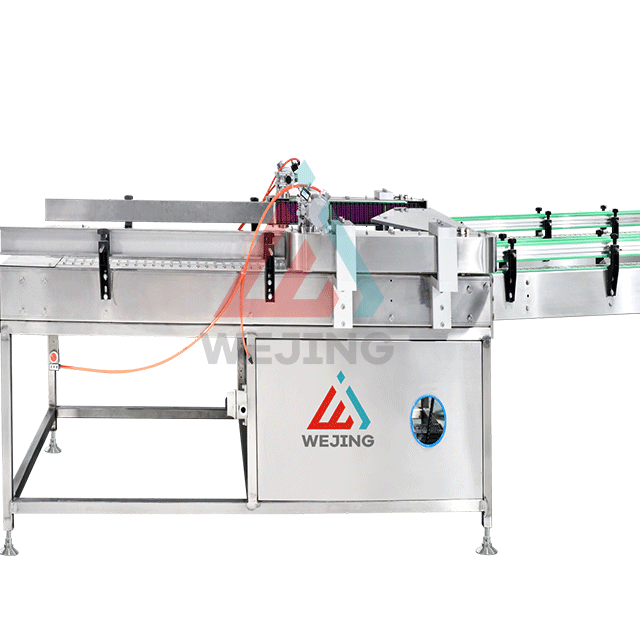

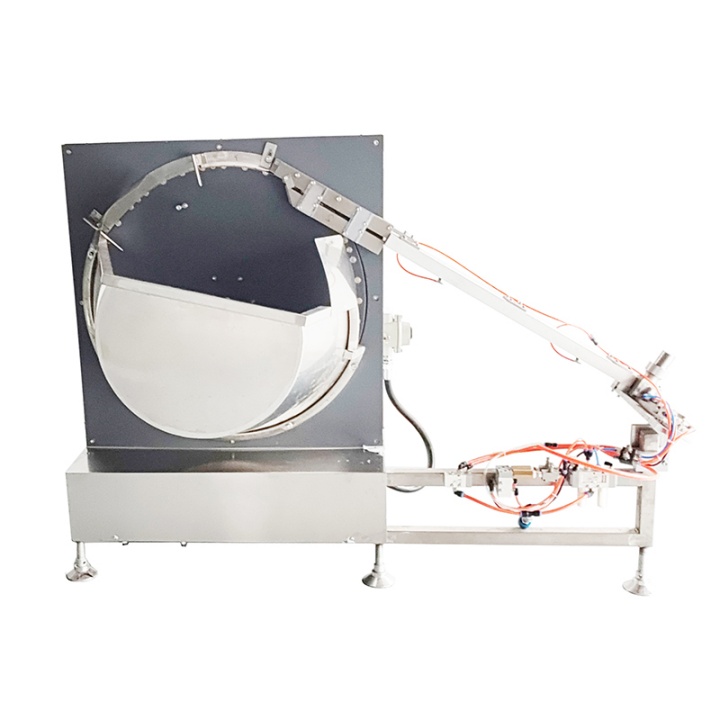

Can feeding Machine

Maintain a proper and organized can feeding pattern along the conveyor belt, ensuring cans are aligned correctly and evenly spaced to prevent blockages and promote a smooth, continuous flow. This task is vital for efficient coordination between different stages of production and contributes to maximized throughput.

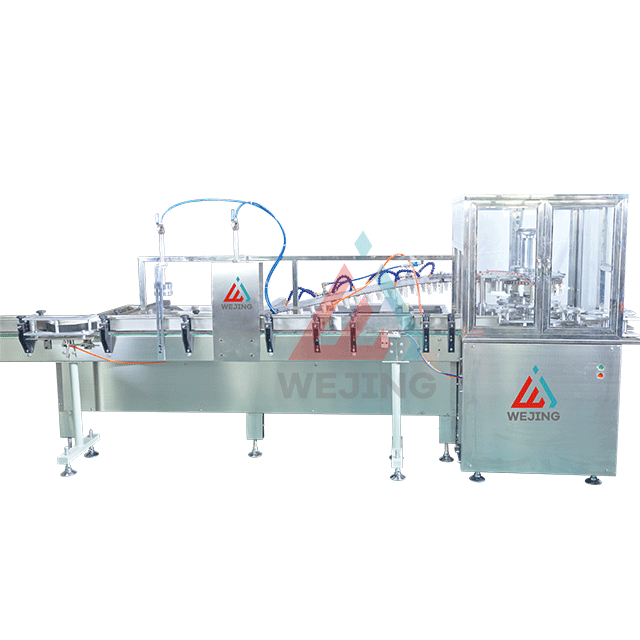

Weight checking machine

Employed for real-time weight scrutiny of individual cans during the aerosol manufacturing process, this system continuously monitors each can's weight as it moves through the production line, thereby ensuring precise adherence to weight specifications and enhancing overall product quality control.

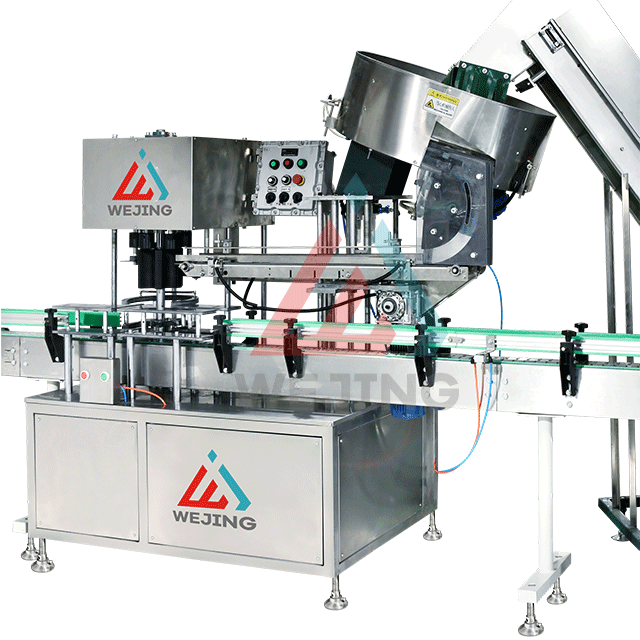

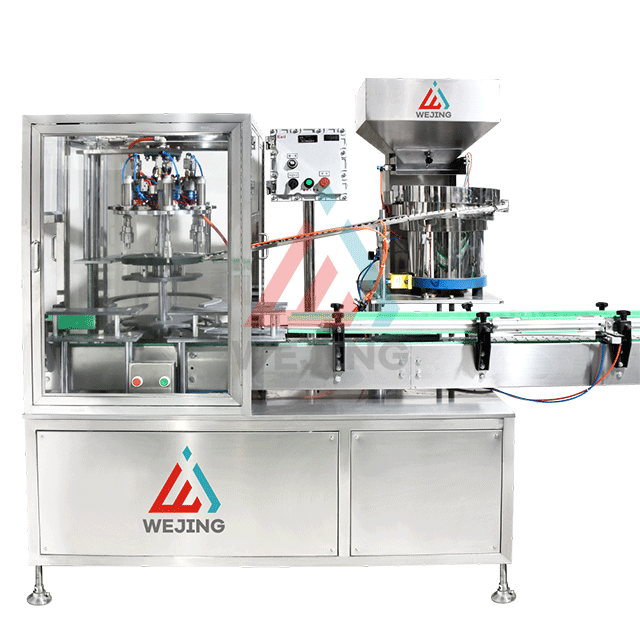

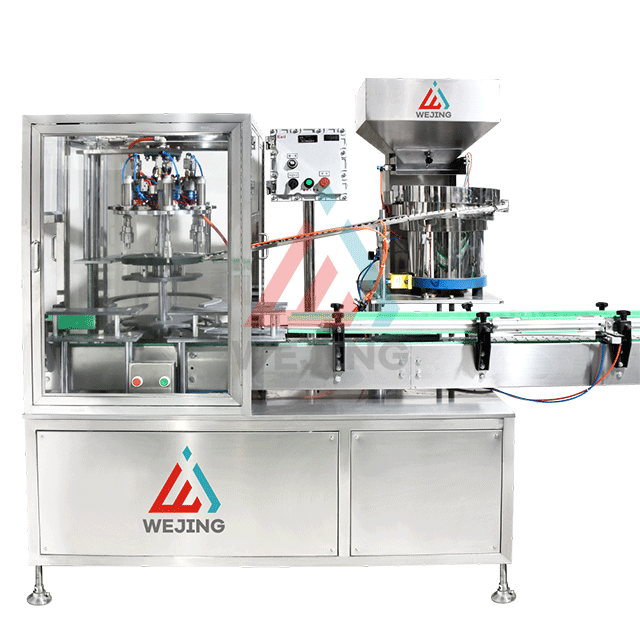

Auto Actuator Fixed Machine

This machinery is specifically designed for the automated and accurate mounting of actuators onto aerosol containers within the production process. It efficiently ensures that each aerosol product has its actuator securely and properly installed, which is a critical step in preparing the final, functional package.

Safety cover Fixed Machine

This specialized equipment serves the purpose of meticulously placing and securing the safety covers on aerosol spray cans during the manufacturing process. Its role is integral in safeguarding the functionality and user safety by effectively installing these protective covers onto each aerosol product, thereby completing a vital assembly stage.

Auto valve inserting machine

Consisting of three core components, this system includes a valve selection apparatus that carefully selects the appropriate valves, followed by a valve insertion mechanism responsible for precisely positioning the valves into the aerosol cans. Lastly, it features a valve pressing device that firmly secures the valves in place, thus forming a cohesive unit that ensures the proper and efficient assembly of aerosol cans.

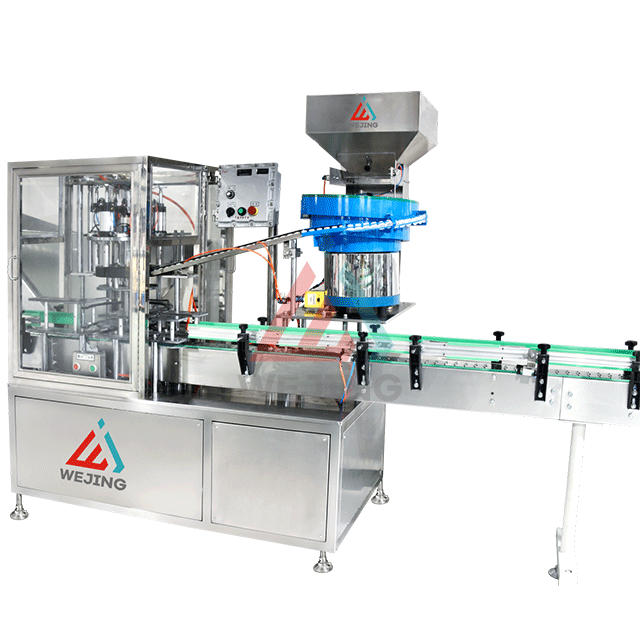

Auto cap presser machine

This dedicated machinery serves the essential function of externally packaging aerosol products with plastic caps, facilitating a secure and aesthetically pleasing finish. It expertly handles the process of picking, aligning, and fixing plastic caps onto each aerosol container, thereby completing a critical step in the overall production and presentation of the final product.

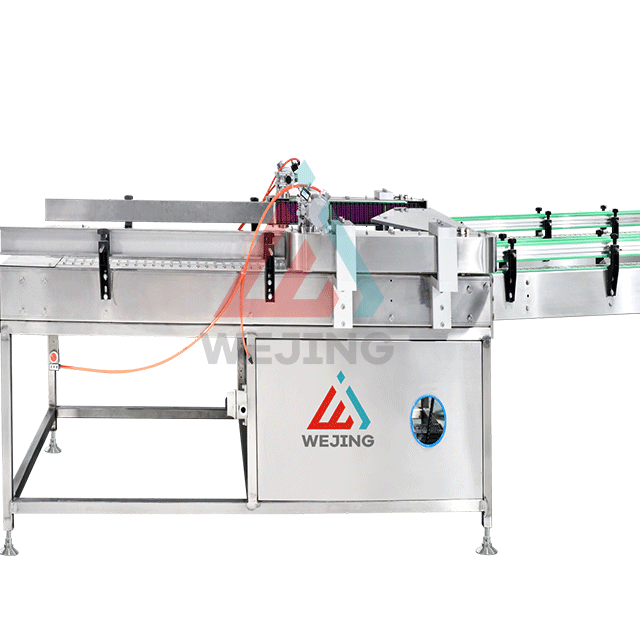

Water bath Detecting Machine

In the process, aerosol cans are systematically grabbed and guided by the mainframe into a dedicated detection slot where they undergo a persistent water bath examination. This automation ensures that each aerosol product is securely held in place before being submerged for thorough testing, providing a seamless and continual quality control measure throughout the production line.

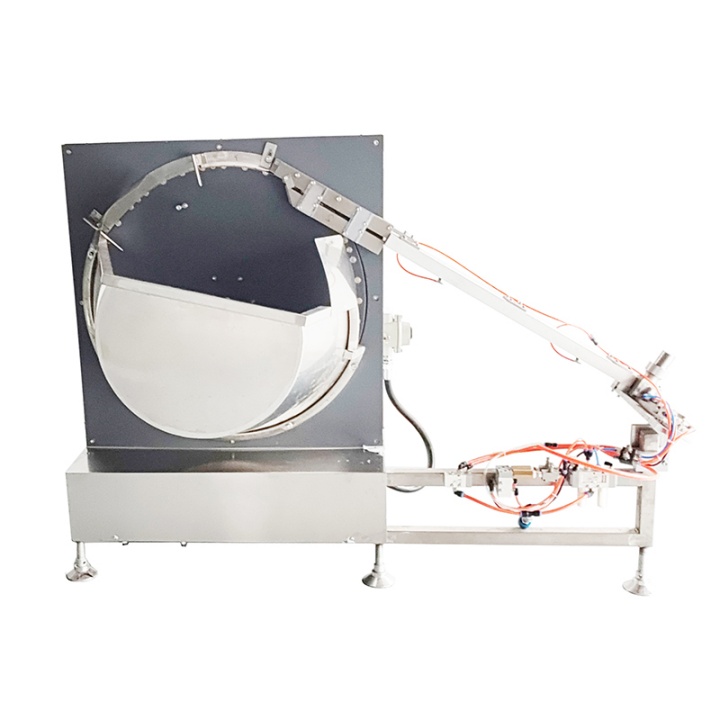

Glass Bead Inserted lachine

Glass Bead Inserted lachine

Featuring a built-in funnel and a state-of-the-art rotary table with a self-selecting glass bead mechanism, this apparatus constitutes an integral component widely employed across multiple industries. Notably, it is commonly seen in automated spray painting operations, the production of festive ribbon decorations, and the cosmetics sector where the inclusion of glass beads is paramount. Its versatility makes it indispensable in processes that necessitate the precise application or incorporation of glass beads.

Products:

1. In the realm of Personal Care, the system handles the packaging of deodorants, hair sprays, and cosmetic products, guaranteeing swift and sanitary encapsulation.

2. For Household Cleaning applications, it reliably fills air fresheners, disinfectants, and cleaning polishes at a consistently high production rate.

3. Within the Pharmaceutical sector, it caters to Metered Dose Inhalers (MDIs), topical formulations, and sanitizing agents, ensuring stringent dosing accuracy and uncompromising cleanliness standards.

4. Serving Industrial purposes, it expertly packages lubricants, bonding agents, and protective coatings with exactitude and rapidity.

FAQ:

Q: What range of goods can be processed using a high-speed aerosol filler?

A: It proficiently packs a broad spectrum of aerosol goods, encompassing deodorants, paints, and a variety of personal grooming essentials.

Q: Is the machine capable of handling aerosol cans of differing dimensions?

A: Indeed, it boasts flexibility, effortlessly adjusting to fill cans of diverse diameters and heights via interchangeable parts.

Q: To what extent is the filling accuracy maintained in these machines?

A: The machines rely on intricate valves and automated mechanisms to uphold a high level of precision, often complemented by integrated weighing scales for fill quantity validation.

Q: Would these machines be fit for filling combustible materials?

A: Absolutely, provided they comply with stringent safety standards such as ATEX certification, making them suitable for dealing with flammable substances.

Q: Are there measures in place to prevent over- or under-filling?

A: Many models incorporate sophisticated weight checking mechanisms that proactively detect and reject cans that don't meet the required fill volume.