It means that when the materials are under the vacuum condition,it makes use of the high shear emulsifier to distribute one orseveral phases to another continuous phase rapidly and evenly.The materials will be processed in the narrow space betweenstator and rotor by strong energy of motion produced by themechanical effect. By the operation of hydraulic shearing.centrifugal extruding,impacting, breaking and turbulence for over100 thousand times per minute, the materials will be dispersedand emulsified instantly and evenly. After reciprocating circulationat high frequency, the fine finished products of stable and highquality without bubbles will be achieved.

PERFORMANCES AND FEATURES

1. The vacuum emulsifiers produced by our company includemany varieties.The homogenizing systems include upperhomogenization, lower homogenization, internal and externalcirculating homogenization. The mixing systems include single-way mixing, double-way mixing and helical ribbon mixing. Thelifting systems include single-cylinder lifting and double-cylinder lifting.Various high quality products can be customized according to customer requirements.

2. The triple mixing adopts the imported frequency converter forspeed adjustment, which can meet different technological demands.

3. The homogenizing structure made through German technologyadopts the imported double-end mechanical seal effect. Themaximum emulsifying rotation speed can reach 4,200rpm andthe highest shearing fineness can reach 0.2-5um.

4. The vacuum defoaming can make the materials meet therequirement of being aseptic. The vacuum material sucking isadopted,and especially for the powder materials, vacuumsucking can avoid dust.

5. The emulsifying pot lid can adopt lifting system, easy to cleanand the cleaning effect is more obvious, the emulsifying pot canadopt tilt discharge.

6. The pot body is welded by imported three-layer stainless steelplate. The tank body and the pipes adopt mirror polishing, which fully conforms to GMP requirements.

7. According to technological requirements, the tank body canheat or cool the materials. The heating modes mainly includesteam heating or electric heating.

8. To ensure the control of the whole machine is more stable, theelectric appliances adopt imported configurations, so as to fullymeet the international standards.

HELICAL RIBON MIXING,INTERNAL AND EXTERNAL CIRCULATING HOMOGENIZATION

MAIN COMPOSITION

The vacuum emulsifying mixer is mainly composed ofwater pot, oil pot,emulsifying pot, vacuum system, lifting system (optional),electric control system (PLC is optional).operation platform, etc.

TECHNICAL PARAMETER

| Model | Capacity | Homogenizer Motor | Stir Motor | Dimension | Total Power(KW) | Limit Vacuum

(Mpa) |

| kw | r/min | kw | r/min | Length(mm) | Width(mm) | Height(mm) | Steam Heating | Electric Heating |

| WJ-LTR100 | 100L | 2.8-4 | 1440/2880 | 1.5 | 0-63 | 2750 | 2700 | 2250/3100 | 13 | 32 | -0.09 |

| WJ-LTR200 | 200L | 6.5-8 | 1440/2880 | 2.2 | 0-63 | 3100 | 3000 | 2500/3450 | 15 | 45 | -0.09 |

| WJ-LTR300 | 300L | 6.5-8 | 1440/2880 | 2.2 | 0-63 | 3500 | 3350 | 2650/3600 | 18 | 49 | -0.085 |

| WJ-LTR500 | 500L | 6.5-8 | 1440/2880 | 4 | 0-63 | 3850 | 3600 | 2750/4000 | 22 | 61 | -0.08 |

| WJ-LTR1000 | 1000L | 9-11 | 1440/2880 | 5.5 | 0-63 | 4200 | 3850 | 3300/4800 | 28 | 88 | -0.08 |

| WJ-LTR2000 | 2000L | 15 | 1440/2880 | 7.5 | 0-63 | 4850 | 4300 | 3800/5400 | 40 | 100 | -0.08 |

TOP HOMOGENIZER WITH PLC SYSTEM

USAGE AND APPLICATION FTELD

The product is mainly appled in such industries as dailychemical care producis,biopharmaceutical industry, foodindustry, paint and ink, nanometer materials, petrochemical industry, printing and dyeing auxiliaries, pulp & paper,pesticide,fertilizer, plastic & rubber, electrics andelectronics,fine chemical industry. etc. The emulsifyingeffect is more prominent for materials of high base viscosityand higih solid content.

TECHNICAL PARAMETER

| Model | Capacity | Homogenizer Motor | Stir Motor | Dimension | Total Power(KW) | Limit Vacuum

(Mpa) |

| kw | r/min | kw | r/min | Length(mm) | Width(mm) | Height(mm) | Steam Heating | Electric Heating |

| WJ-LTP5 | 5L | 0.37 | 0-3000 | 0.18 | 0-63 | 1260 | 540 | 1600/1850 | 2 | 5 | -0.09 |

| WJ-LTP10 | 10L | 0.75 | 0-3000 | 0.37 | 0-63 | 1300 | 580 | 1600/1950 | 3 | 6 | -0.09 |

| WJ-LTP50 | 50L | 3-5.5 | 0-3000 | 1.1 | 0-63 | 2600 | 2250 | 1950/2700 | 9 | 18 | -0.09 |

| WJ-LTP100 | 100L | 4-7.5 | 0-3000 | 1.5 | 0-63 | 2750 | 2380 | 2100/2950 | 13 | 32 | -0.09 |

| WJ-LTP200 | 200L | 5.5-11 | 0-3000 | 2.2 | 0-63 | 2750 | 2750 | 2350/3350 | 15 | 45 | -0.09 |

| WJ-LTP300 | 300L | 7.5-11 | 0-3000 | 2.2 | 0-63 | 2900 | 2850 | 2450/3500 | 18 | 49 | -0.085 |

| WJ-LTP500 | 500L | 11 | 0-3000 | 4 | 0-63 | 3650 | 3300 | 2850/4000 | 24 | 63 | -0.08 |

| WJ-LTP1000 | 1000L | 15 | 0-3000 | 5.5 | 0-63 | 4200 | 3650 | 3300/4800 | 30 | 90 | -0.08 |

| WJ-LTP2000 | 2000L | 15 | 0-3000 | 7.5 | 0-63 | 4850 | 4300 | 3800/5400 | 40 | _ | -0.08 |

TOP HOMOGENIZER DOUBLE-WAY MIXING

Discription

Vacuum Homogenizing & Emulsifying is indispensableequipment to paste honey and is very useful experimenttool in cosmetic factory with complete function and highguality.

Specification: 50L,100L,200L,300L,500L. Type:Hydraulic lifting Pneumatic lifting.

TECHNICAL PARAMETER

| Model | Capacity | Homogenizer Motor | Stir Motor | Dimension | Total Power(KW) | Limit Vacuum

(Mpa) |

| kw | r/min | kw | r/min | Length (mm) | Width (mm) | Height (mm) | Steam Heating | Electric Heating |

| WJ-LTP5 | 5L | 0.37 | 0-3000 | 0.18 | 0-63 | 1260 | 540 | 1600/1850 | 2 | 5 | -0.09 |

| WJ-LTP10 | 10L | 0.75 | 0-3000 | 0.37 | 0-63 | 1300 | 580 | 1600/1950 | 3 | 6 | -0.09 |

| WJ-LTP50 | 50L | 3-5.5 | 0-3000 | 1.1 | 0-63 | 2600 | 2250 | 1950/2700 | 9 | 18 | -0.09 |

| WJ-LTP100 | 100L | 4-7.5 | 0-3000 | 1.5 | 0-63 | 2750 | 2380 | 2100/2950 | 13 | 32 | -0.09 |

| WJ-LTP200 | 200L | 5.5-11 | 0-3000 | 2.2 | 0-63 | 2750 | 2750 | 2350/3350 | 15 | 45 | -0.09 |

| WJ-LTP300 | 300L | 7.5-11 | 0-3000 | 2.2 | 0-63 | 2900 | 2850 | 2450/3500 | 18 | 49 | -0.085 |

| WJ-LTP500 | 500L | 11 | 0-3000 | 4 | 0-63 | 3650 | 3300 | 2850/4000 | 24 | 63 | -0.08 |

| WJ-LTP1000 | 1000L | 15 | 0-3000 | 5.5 | 0-63 | 4200 | 3650 | 3300/4800 | 30 | 90 | -0.08 |

| WJ-LTP2000 | 2000L | 15 | 0-3000 | 7.5 | 0-63 | 4850 | 4300 | 3800/5400 | 40 | _ | -0.08 |

FIXED POT, BOTTOM HOMOGENIZER WITH INTERNAL AND EXTERNAL CIRCULATION

TECHNICAL PARAMETER

| Model | Capacity | Homogenizer Motor | Stir Motor | Dimension | Total Power(KW) | Limit Vacuum

(Mpa) |

| kw | r/min | kw | r/min | Length(mm) | Width(mm) | Height(mm) | Steam Heating | Electric Heating |

| WJ-V100 | 100L | 2.8-4 | 1440/2880 | 1.5 | 0-63 | 2750 | 2700 | 2250 | 13 | 32 | -0.09 |

| WJ-V200 | 200L | 6.5-8 | 1440/2880 | 2.2 | 0-63 | 3100 | 3000 | 2500 | 15 | 45 | -0.09 |

| WJ-V300 | 300L | 6.5-8 | 1440/2880 | 2.2 | 0-63 | 3500 | 3350 | 2650 | 18 | 49 | -0.085 |

| WJ-V500 | 500L | 6.5-8 | 1440/2880 | 4 | 0-63 | 3850 | 3600 | 2750 | 22 | 61 | -0.08 |

| WJ-V1000 | 1000L | 9-11 | 1440/2880 | 5.5 | 0-63 | 4200 | 3850 | 3300 | 28 | 88 | -0.08 |

| WJ-V2000 | 2000L | 11-14 | 1440/2880 | 5.5 | 0-63 | 4500 | 4050 | 3800 | 34 | _ | -0.08 |

| WJ-V3000 | 3000L | 15-18 | 1440/2880 | 7.5 | 0-63 | 4800 | 4300 | 4100 | 40 | _ | -0.08 |

BOTTOM HOMOGENIZER DOUBLE-WAY MIXING

DISCRIPTION

WJ-ED series vacuum emulsifying machine adopt advanced overseas technology. lt is specially designed forcosmetic cream and pharmaceutical cream products. Thewhole system is consist of water pot, oil pot, main pot,vacuum pump, hydraulic system, tilting discharge system,electric controlling system, platform etc.

TECHNICAL PARAMETER

| Model | Capacity | Homogenizer Motor | Stir Motor | Dimension | Total Power(KW) | Limit Vacuum

(Mpa) |

| kw | r/min | kw | r/min | Length(mm) | Width(mm) | Height(mm) | Steam Heating | Electric Heating |

| WJ-LBD5 | 5L | 0.37 | 0-3000 | 0.18 | 0-63 | 1260 | 540 | 1600/1850 | 2 | 5 | -0.09 |

| WJ-LBD10 | 10L | 0.75 | 0-3000 | 0.37 | 0-63 | 1300 | 580 | 1600/1950 | 3 | 6 | -0.09 |

| WJ-LBD50 | 50L | 3-5.5 | 0-3000 | 1.1 | 0-63 | 2600 | 2250 | 1950/2700 | 9 | 18 | -0.09 |

| WJ-LBD100 | 100L | 4-7.5 | 0-3000 | 1.5 | 0-63 | 2750 | 2380 | 2100/2950 | 13 | 32 | -0.09 |

| WJ-LBD200 | 200L | 5.5-11 | 0-3000 | 2.2 | 0-63 | 2750 | 2750 | 2350/3350 | 15 | 45 | -0.09 |

| WJ-LBD300 | 300L | 7.5-11 | 0-3000 | 2.2 | 0-63 | 2900 | 2850 | 2450/3500 | 18 | 49 | -0.085 |

| WJ-LBD500 | 500L | 11 | 0-3000 | 4 | 0-63 | 3650 | 3300 | 2850/4000 | 24 | 63 | -0.08 |

| WJ-LBD1000 | 1000L | 15 | 0-3000 | 5.5 | 0-63 | 4200 | 3650 | 3300/4800 | 30 | 90 | -0.08 |

| WJ-LBD2000 | 2000L | 15 | 0-3000 | 7.5 | 0-63 | 4850 | 4300 | 3800/5400 | 40 | _ | -0.08 |

VACUUM PASTE CREAM MACHINE

DISCRIPTION

The vacuum machine produced by our company is widely used for manufacturing paste-like products, toothpaste,cosmetics, foods and chemistry industry, etc. This equipment includes paste machine, pre-mix boiler.gluewater boiler, powder material hopper, colloid pumpand operation platform.

TECHNICAL PARAMETER

Type

| Volume

(L) | Power of Vaccum Pump

(kw) | Hydraulic Pump

(kw) | lifting Height of Vessel Cover

(mm) | Dimension(LxWxH)

(mm) | Weight

(kg) |

WJ-TP100

| 100

| 3 | 1.1

| 800 | 2450x1500x2040 | 2500

|

| WJ-TP700 | 700 | 4 | 1.5 | 1000 | 4530x3800x2480 | 3000 |

| WJ-TP1300 | 1300 | 7.5 | 2.2 | 1000 | 1920x3910x3200

| 4500 |

LIPSTICK MACHINE

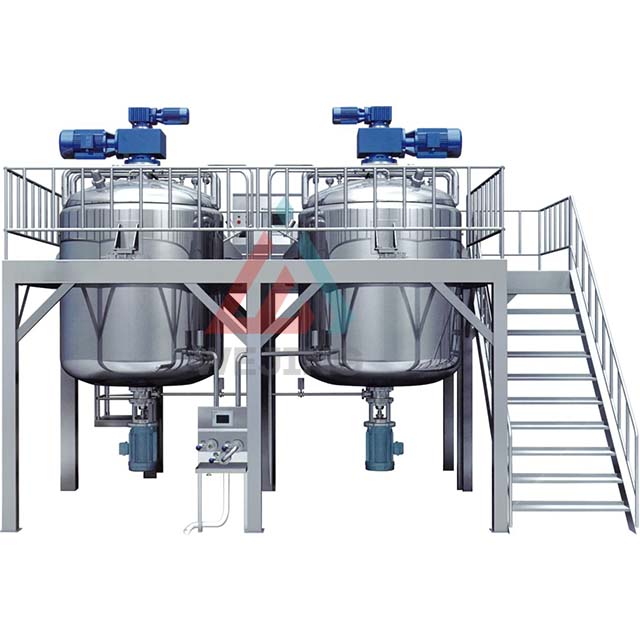

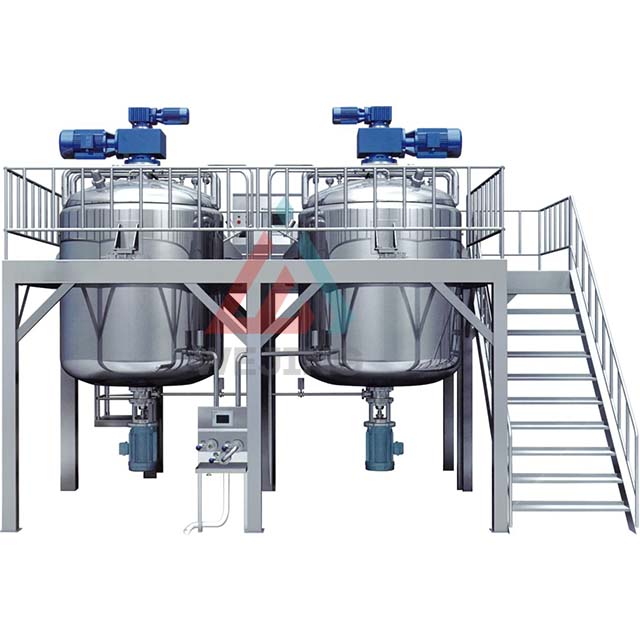

LIQUID WASHING HOMOGENIZING MIXER

USAGE

This unit is available for manufacturing liquid products (such asdetergent,shampoo, shower gel, etc.), it integrates mixing.homogenizing,heating,cooling, pump discharging finished products and defoaming (optional) functions. lt is the idealequipment for liquid products in domestic and international factories.

TECHNICAL PARAMETER

| Model | Capacity

(L) | Mixing Power

(kw) | Mixing Speed

(r/min) | Homogenizing Power

(kw) | Homogenizing Speed

(r/min) | Heating Method

|

| WJ-M200 | 200

| 0.75

| 0-65 | 2.2-4

| 3000 | Steam Heating or Electric Heating (optional) |

| WJ-M300 | 300 | 0.75 | 0-65 | 2.2-4 | 3000 |

| WJ-M500 | 500 | 2.2

| 0-65 | 5.5-7.5 | 3000 |

| WJ-M1000 | 1000 | 4

| 0-65 | 5.5-7.5 | 3000 |

| WJ-M2000 | 2000 | 5.5 | 0-53 | 11-15 | 3000 |

| WJ-M3000 | 3000 | 7.5 | 0-53 | 18 | 3000 |

| WJ-M5000 | 5000 | 11 | 0-42 | 22 | 3000 |

| WJ-M10000 | 10000 | 15 | 0-42 | 30 | 3000 |