Product Advantage:

1. High efficiency and productivity: The automated production line can complete the capping process of aerosol spray cans quickly and accurately, improving production efficiency and output.

2. High precision and quality: Equipped with precision capping devices and control systems, the production line ensures the accuracy and consistency of the capping operation, improving product quality.

3. Flexible production: The production line can adjust the production speed and process parameters according to different product specifications and production requirements, realizing flexible production.

4. Easy to operate and maintain: The interface of the equipment is simple and intuitive, and the maintenance is convenient, reducing the difficulty of operator training and maintenance costs.

5. Safety and reliability: Designed with multiple safety protection devices, the production line ensures the safety and reliability of the production process, reducing the risk of accidents.

Technical Parameters:

Technical Parameter | Description |

Speed | ≥ 120 bottles /min |

Suitable can diameter | 35-70mm |

Suitable can height | 70-330mm |

Control | Electricity control |

Alarm system | Equipped with uncovered alarm device |

Air source | 0.8Mpa |

Power | 2kW |

Size | 1900*1700*850mm |

Weight | 300kg |

Product Uses:

1. Personal care and hygiene: The production line is suitable for packaging personal care products like hairspray, deodorant, and sunscreen spray.

2. Home improvement and cleaning: It can be used for packaging household products such as air fresheners, furniture polish sprays, and carpet cleaners.

3. Automotive and industrial: The line is ideal for packaging automotive and industrial products like lubricants, paints, and adhesives.

4. Gardening and agriculture: It can be employed in packaging garden and agricultural products such as plant fertilizers, pesticides, and herbicides.

5. Medical and pharmaceutical: The production line is suitable for packaging medical and pharmaceutical products like nasal sprays, asthma inhalers, and disinfectant sprays.

Product Operate Guide:

1. Pre-startup inspection: Before starting the equipment, ensure that all components are properly installed and connected. Check if the power supply, air source, and conveyor belt are functioning normally.

2. Adjust parameters: According to the requirements of different products, adjust the parameters of the equipment, such as pressure, speed, and temperature, to ensure the best capping effect.

3. Feeding and conveying: Place the aerosol cans waiting for capping on the conveyor belt, and ensure an appropriate spacing between the cans to avoid congestion or missed caps.

4. Start the equipment: After confirming that all preparations are complete, start the equipment. Observe the operation of the equipment to ensure a smooth capping process.

5. Quality inspection: Regularly check the quality of the caps, such as sealability and appearance. If any problems are found, adjust the equipment parameters or carry out maintenance promptly.

Please note that this is only a basic operating guide, and the specific operating steps and precautions may vary depending on the equipment model and production requirements. Before operating the equipment, please carefully read the operating manual and follow the instructions of professionals.

FAQ:

1. What is the Capping Machine Production Line for Aerosol Spray Can?

The Capping Machine Production Line is a fully automated system designed for the production of aerosol spray cans. It performs various functions such as filling, crimping, and capping the cans with lids to ensure a secure and leak-proof seal.

2. How does the Capping Machine Production Line work?

The production line works by automatically feeding empty cans, filling them with the desired product, and then crimping and securing the lids. It utilizes advanced technologies and precise control systems to ensure high productivity and consistent quality.

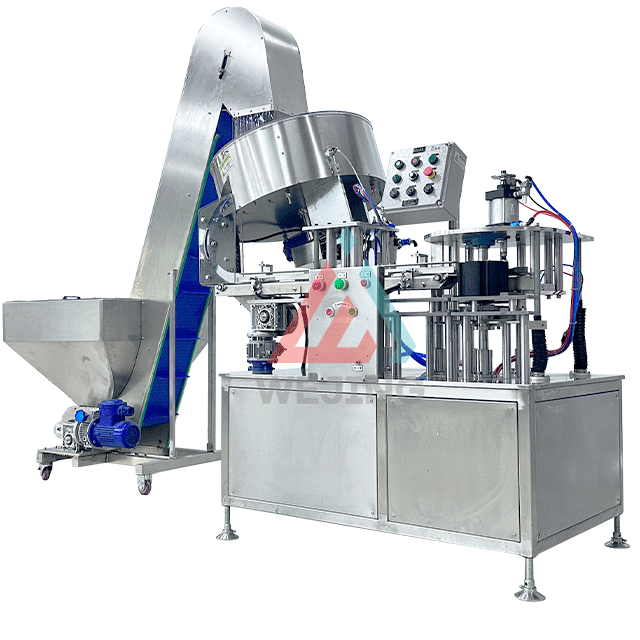

3. What are the key components of the Capping Machine Production Line?

The key components of the capping machine production line include a conveyor system, filling machines, crimping devices, cap feeding mechanisms, and inspection stations. These components work together to ensure efficient and precise operation during the can filling and capping process.

4. Can the production line handle different can sizes and shapes?

Yes, the Capping Machine Production Line is designed to handle a variety of can sizes and shapes. It can be customized and adjusted to accommodate different dimensions and configurations, allowing for flexibility in production requirements.

5. How is quality control ensured during the production process?

Quality control is ensured through various inspection stations incorporated into the production line. These stations include visual inspection for any defects, leak testing to ensure proper seals, and cap alignment verification. By implementing these quality control measures, defects can be minimized, and the integrity and safety of the aerosol spray cans are ensured.