(1) Core process

Liquid filling → sealing → gas filling

This streamlined process is suitable for the production of most conventional aerosols, avoiding complex process changes and ensuring stable and continuous production.

(2) Equipment features

n Customizable capacity: adapted to the development stage of different sized companies. Small semi-automatic models can reach a capacity of 20 cans per minute, while large modular assembly lines can extend capacity to 150 cans per minute by adding filling heads and increasing conveyor speed.

n Strong compatibility: Supporting different tank sizes, it can handle medium-viscosity liquids, which reduces the cost of equipment replacement during production changeover.

n Convenient operation: Equipped with bilingual HMI (Human Machine Interface), operators can master parameter setting and troubleshooting skills in 1-2 weeks.

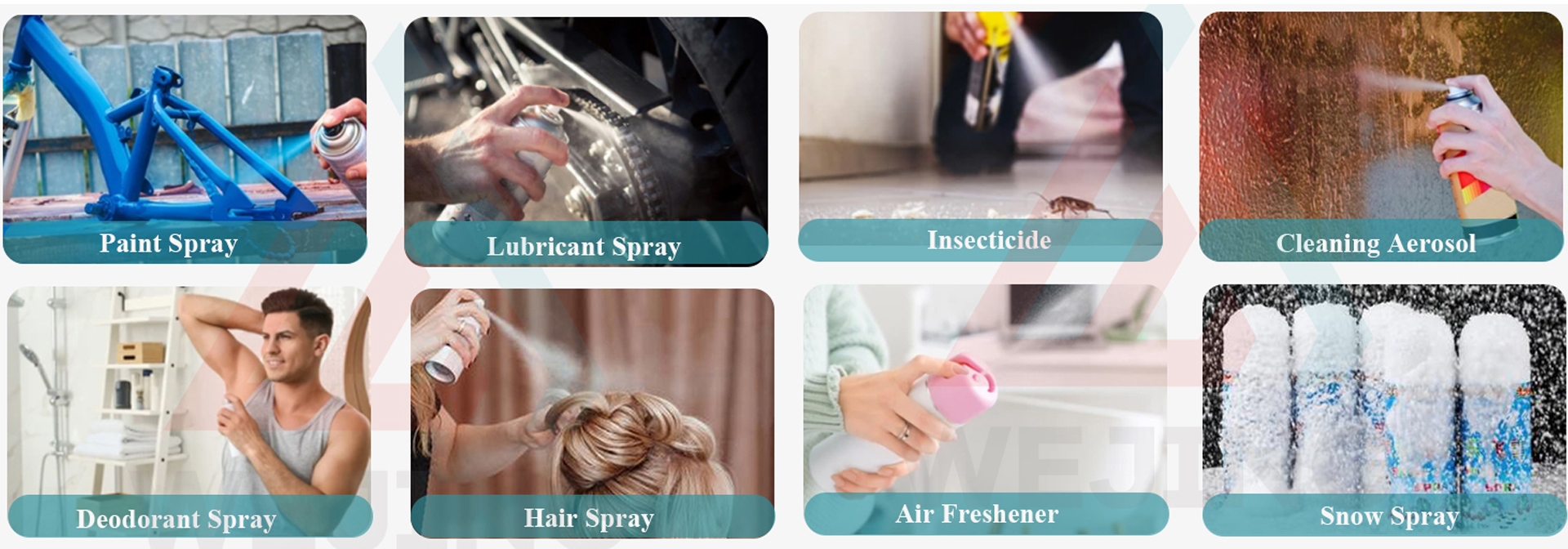

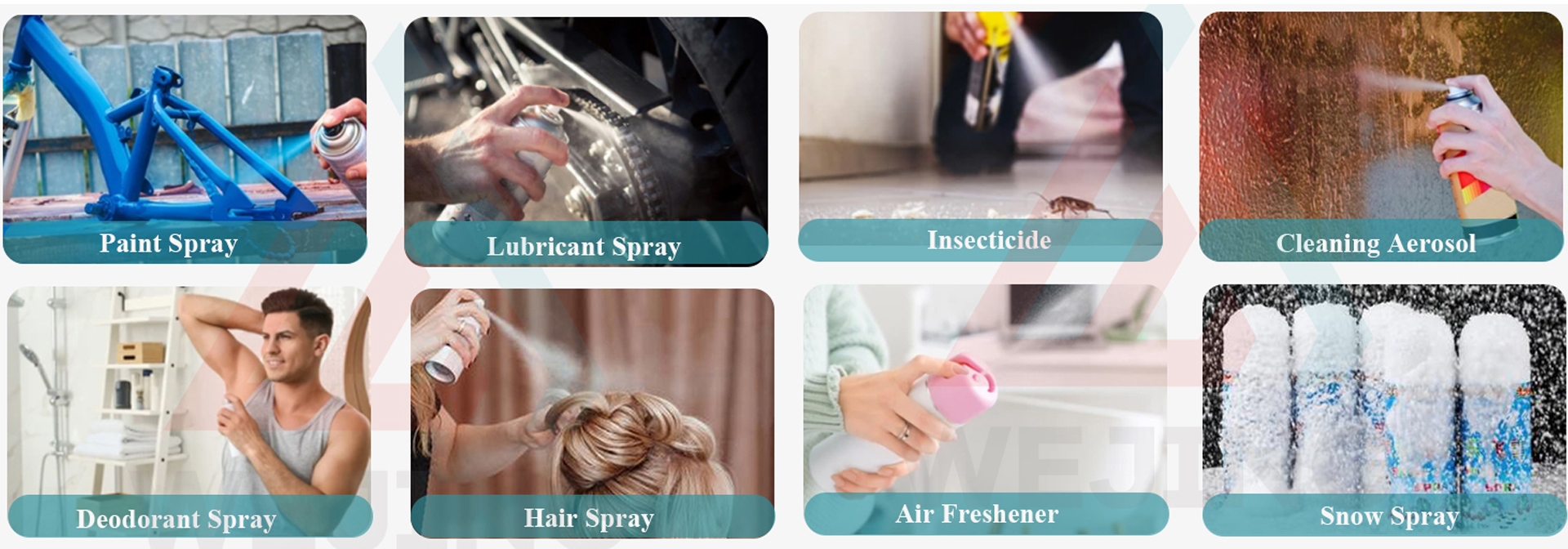

(3) Core Application Areas

Widely used in daily and industrial aerosol industries with high demand, such as:

n Industrial cleaning (e.g., precision parts cleaner)

n Daily chemicals (e.g., styling sprays)

n Home care (e.g., furniture polish)

n Insecticides (e.g., household mosquito repellent sprays)

n Typical Product Examples

n Self-spraying paints, aerosol cleaners, air fresheners, household insecticides, automotive interior cleaners, hairspray gels, lubricating fluids.

(1) Core process

Gas filling and sealing → Liquid filling

Unique “first inflate and then liquid injection” process combined with the built-in inner bag, which fundamentally solves the problem of chemical reaction between the active ingredient and the propellant.

(2) Equipment features

n Isolation protection: built-in food-grade/medical-grade inner bag to isolate the liquid raw materials from the tank and propellant, effectively solving the packaging problems of strong corrosive raw materials (such as strong acids and alkalis), so that the shelf life of the product is extended by more than 50%.

n Aseptic operation: for pharmaceutical and cosmetic products, the production line can be equipped with 100,000 clean room and ultraviolet sterilization system to meet the requirements of GMP standards.

n Precise dosing: The liquid filling system adopts servo motor-driven piston pumps, with a filling accuracy of ±1%, ensuring uniform dosage for each can.

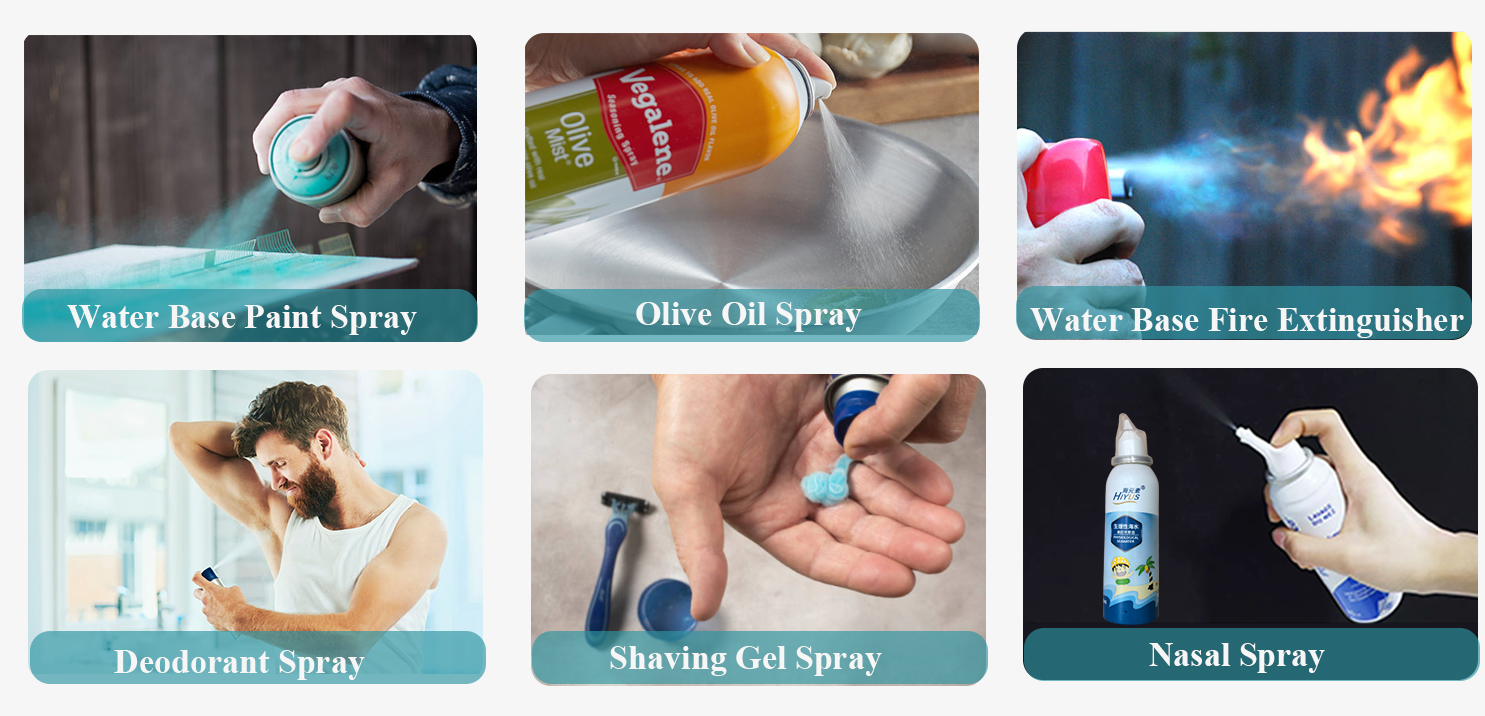

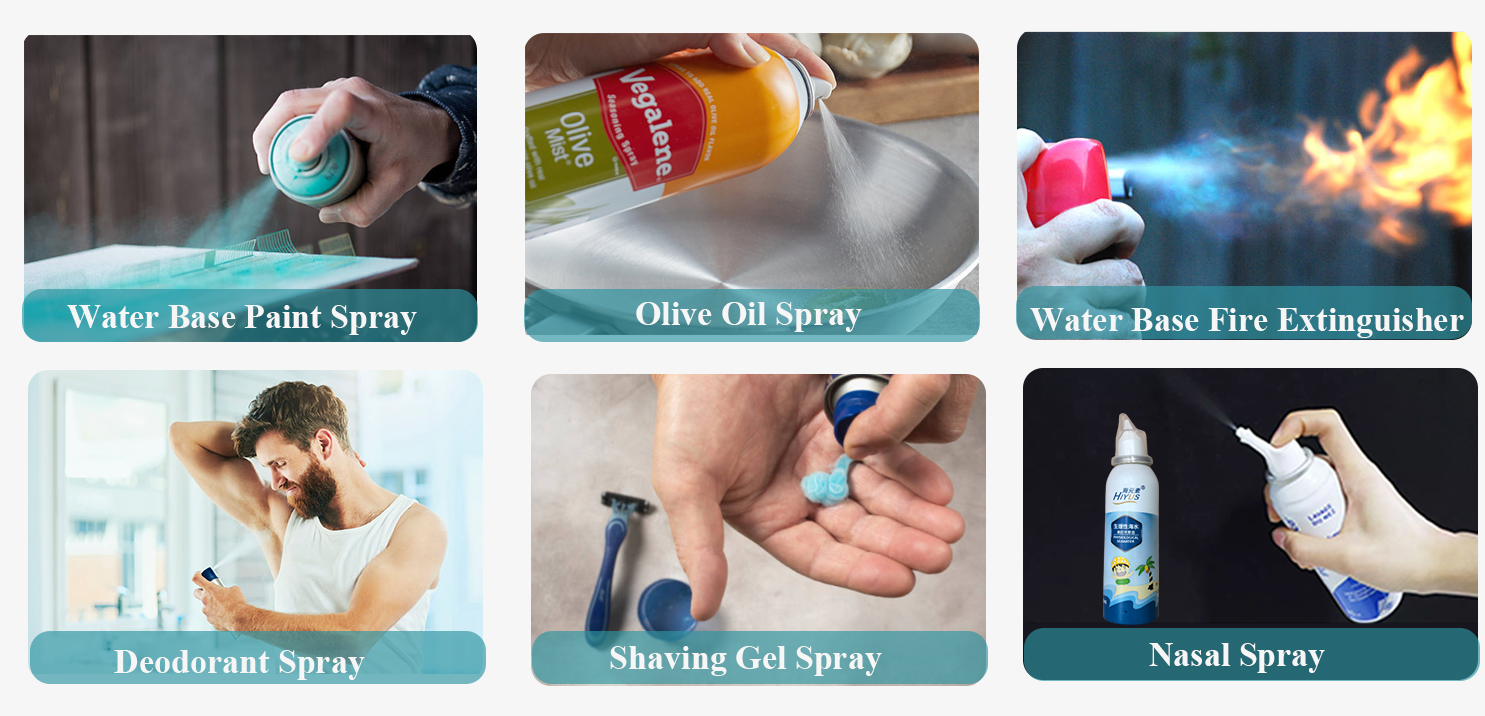

(3) Typical Product Examples

n Nasal Spray

n Olive Oil Spray

n Deodorant Spray

n Shaving Gel Spray

n Water Base Paint Spray

n Water Base Fire Extinguisher

(1) Core Process

Vacuum Pumping → Gas Filling → Sealing

Pre-vacuum step can remove the residual air in the tank, ensure the purity of the filled gas, and avoid the hidden danger caused by gas mixing.

(2) Equipment Features

n High filling accuracy: Adopting negative pressure compensation technology and high-precision pressure sensor, the gas filling accuracy is controlled at ±1% to ensure stable product performance.

n Safety Protection: Equipped with multiple safety mechanisms, including automatic pressure relief for overpressure, emergency stop button and gas leakage detection and alarm, in line with ISO 10297 and other international safety standards.

n Corrosion resistance: gas contact parts are made of 316L stainless steel, which can resist corrosion of most inert gases and hydrocarbon gases, extending the service life of the equipment to 8-10 years.

(3) Core Application Areas

n Focus on storage and transportation scenarios with stringent requirements for gas purity and pressure stability:

n Gas storage (e.g. small portable cylinders)

n Medical oxygen supply (e.g. home oxygen therapy cylinders)

n Refrigeration equipment (e.g. air conditioner refrigerant charging)

n Lighter fuel (e.g. butane gas canisters)

(4) Typical Product Examples

Outdoor stove gas canisters, portable oxygen cylinders, refrigerant canisters (R32/R410A), and lighter fuel canisters.

4. Foam Sealant Specialized Filling Line

(1) Core Process

Initial liquid filling → second liquid filling → sealing → initial gas filling → second gas filling

Dual-liquid and dual-gas filling process ensures accurate foam sealant composition ratio and stable foaming performance.

(2) Technical breakthroughs and equipment features

n Double-liquid filling technology: independently control the filling amount of two-component raw materials (polyol and isocyanate), with a ratio adjustment range of 1:1 to 3:1, ensuring that the foam has excellent adhesion and compression resistance.

n Dynamic pressure adjustment: The gas filling system adopts a proportional pressure valve, which adjusts the pressure in real time according to the ambient temperature (5℃-35℃), and controls the foam expansion rate stably in the range of 300%-600%, which can satisfy the strict construction requirements (e.g. avoiding the deformation of windows and doors due to over-expansion).

n Anti-clogging design: The filling nozzle is equipped with an automatic cleaning channel, and solvent can be used to remove the residual material every shift, avoiding nozzle clogging and reducing maintenance costs.

(3) Core application areas

n Designed for the production of foam sealants for the building and decoration industry:

n Building sealing (e.g. wall and window gap sealing)

n Window and door installation (e.g. door frame bonding and sealing)

n Duct filling (e.g. water pipe, air conditioning pipe insulation sealing)

Selection Guide: How to Match Your Production Needs

In order to select the most suitable aerosol filling line, companies need to consider three core elements:

(1) Capacity Requirements

n For small businesses (annual production <500,000 cans): it is recommended to start with semi-automatic equipment (e.g., semi-automatic general purpose filling machine with a capacity of 5-15 cans per minute). Initial investment is low (~$4-6k) and can be upgraded to a fully automated line at a later stage.

n Medium-sized enterprises (annual production capacity of 500,000-5 million cans): choose a modular design of small fully automatic production line (30-100 cans per minute), with additional filling heads or conveyor lines as capacity grows.

n Large-scale enterprises (annual production capacity >5,000,000 cans): Priority is given to the use of large-scale fully automated assembly lines (130-150 cans / min), to achieve continuous production around the clock.

(2) Product characteristics

n Liquid viscosity: low viscosity liquids (e.g., water-based detergents) choose gravity filling system; high viscosity liquids (e.g., creamy shaving foam) use piston filling system.

n Packaging specifications: if the production of a variety of tank specifications, the need to choose the production line equipped with a rapid can changer (mold change time < 30 minutes); BOV packaging must be equipped with a dedicated BOV production line.

(3) Compliance Requirements

n Food and Pharmaceutical Industry: The equipment must comply with GMP standards, with food grade 304 stainless steel for material contact parts, and equipped with CIP (Cleaning in Place) system.

n Hazardous chemicals (e.g. pesticides, alcohol sprays): the production line must be certified as explosion-proof (e.g. ATEX Zone 1, NEC Class I Zone 1) and equipped with anti-static conveyor belts.

n International market: export to EU needs to meet CE standards; US market needs to meet FDA and OSHA requirements.

Conclusion

From general daily chemical products to professional medical gases and construction foam sealants, the four mainstream aerosol filling lines meet the diversified needs of the industry through technological innovation. With the development of smart manufacturing, modern filling lines are integrating IoT, AI and other technologies to achieve higher efficiency, precision and safety.

For customized equipment selection solutions (e.g., calculating the required capacity based on product type and annual production, or recommending compliant equipment for a specific market), please click on “Enquire Now”. Our technical team with more than 10 years of experience will provide a one-stop solution to help you build an efficient and safe aerosol production system.